In-space-capsule 3D printing device for microgravity environment

A 3D printing and microgravity technology, applied in the field of 3D printing, to achieve the effect of reducing motion vibration interference, high scientific value and application value, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

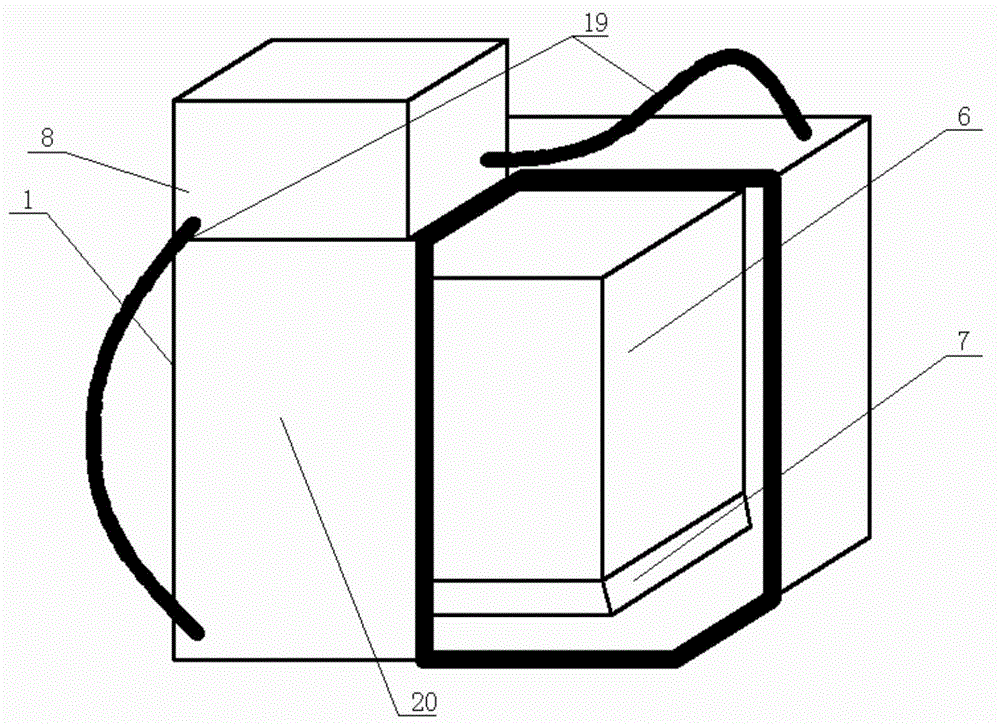

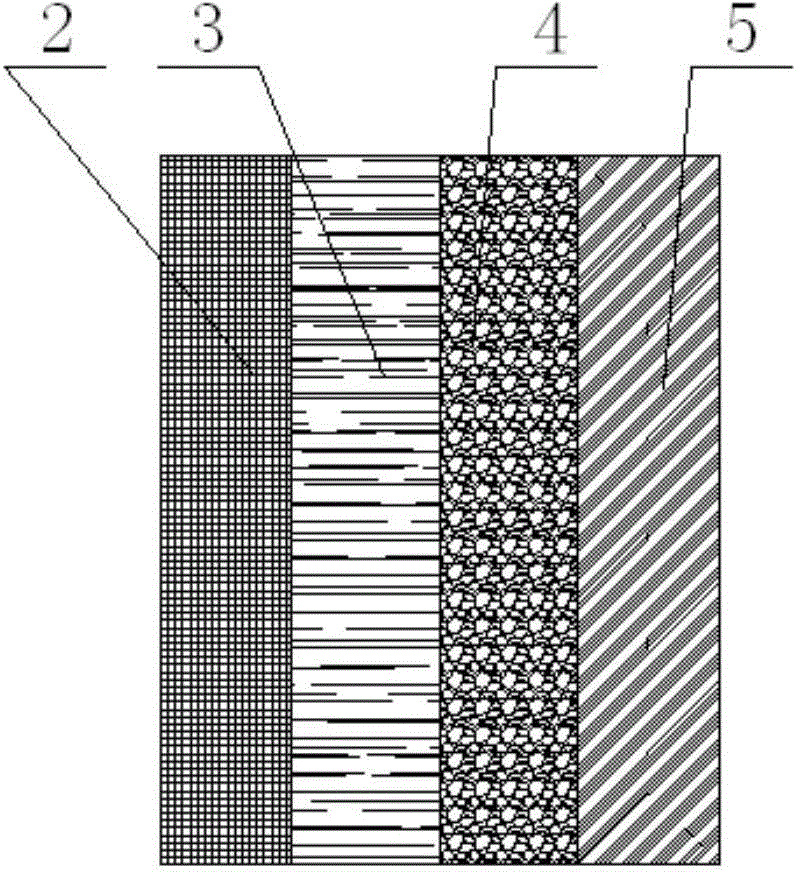

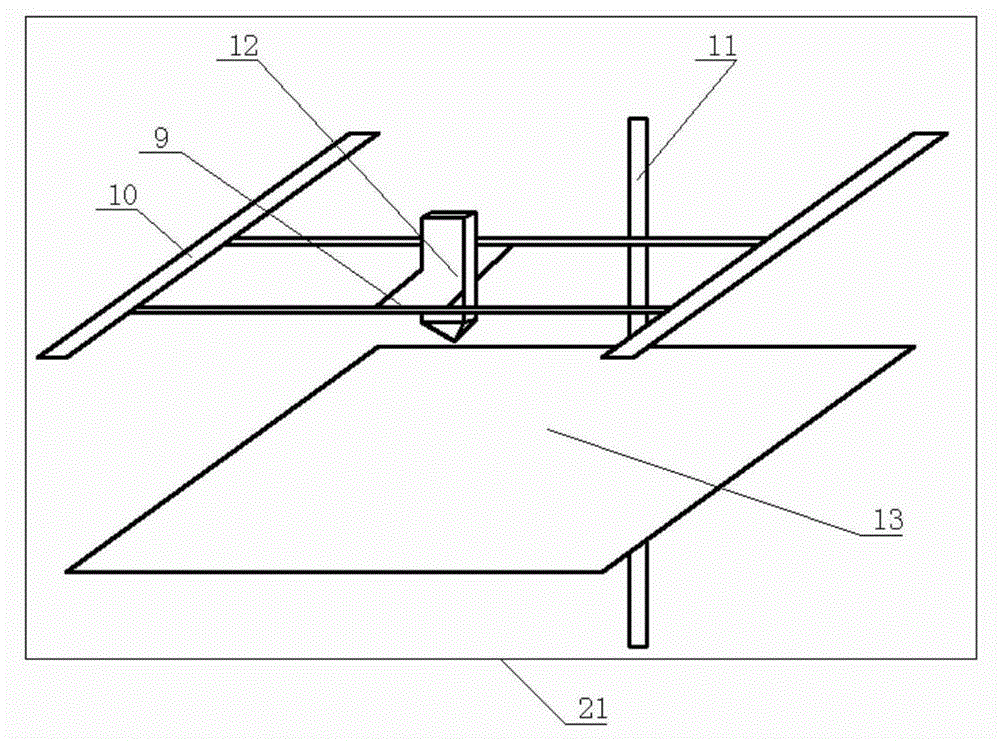

[0025] refer to figure 1 , a 3D printing device in a space capsule facing a microgravity environment, including a printer 20, the exterior of the printer 20 is a functional composite closed casing 1, and the air outlet of the printer 20 in the functional composite closed casing 1 passes through an air guide hose 19 Connect the air inlet of the atmosphere and temperature control device 8, send the gas in the printer 20 into the atmosphere and temperature control device 8 through the air guide hose 19, and connect the air outlet of the atmosphere and temperature control device 8 through the air guide hose 19 The air intake hole of the printer 20 in the composite closed casing 1, the atmosphere and temperature control device 8 filter and purify the gas and control the temperature of the gas, and then send it into the printer 20. The forced convection process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com