Discharging device for medical accessory assembling machine

A technology of assembling machine and blanking, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of poor blanking reliability, poor stability and reliability, and unsuccessful blanking, and achieve reliable and safe blanking process. High and stable effect of blanking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

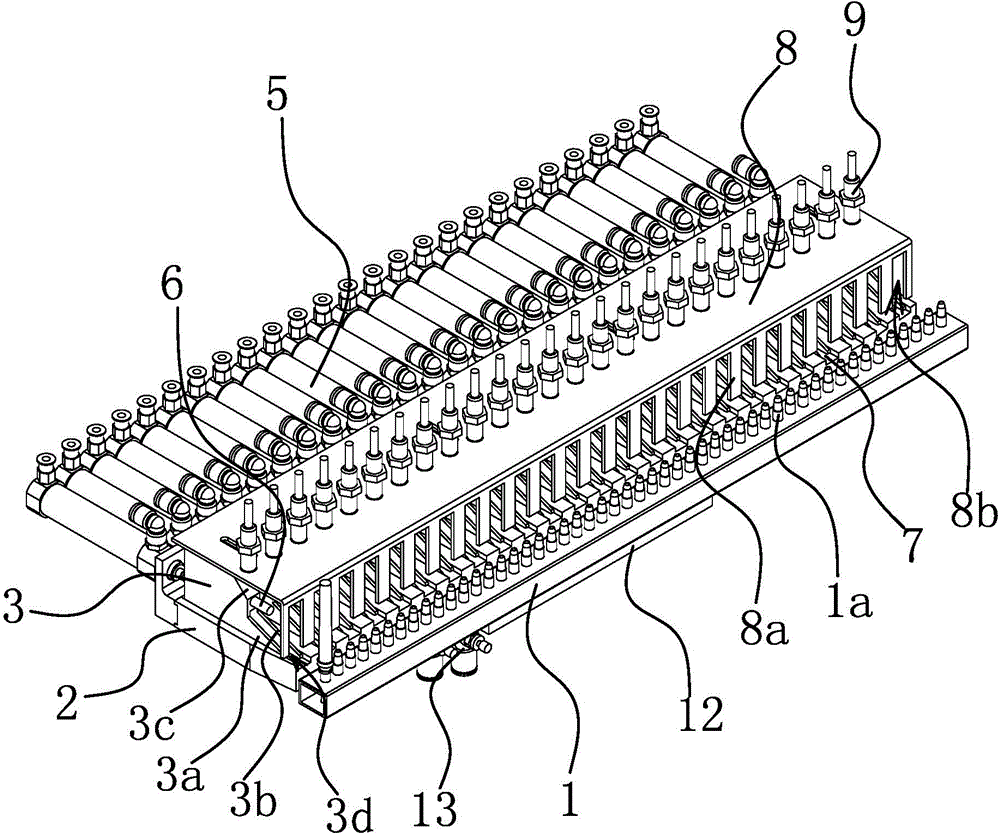

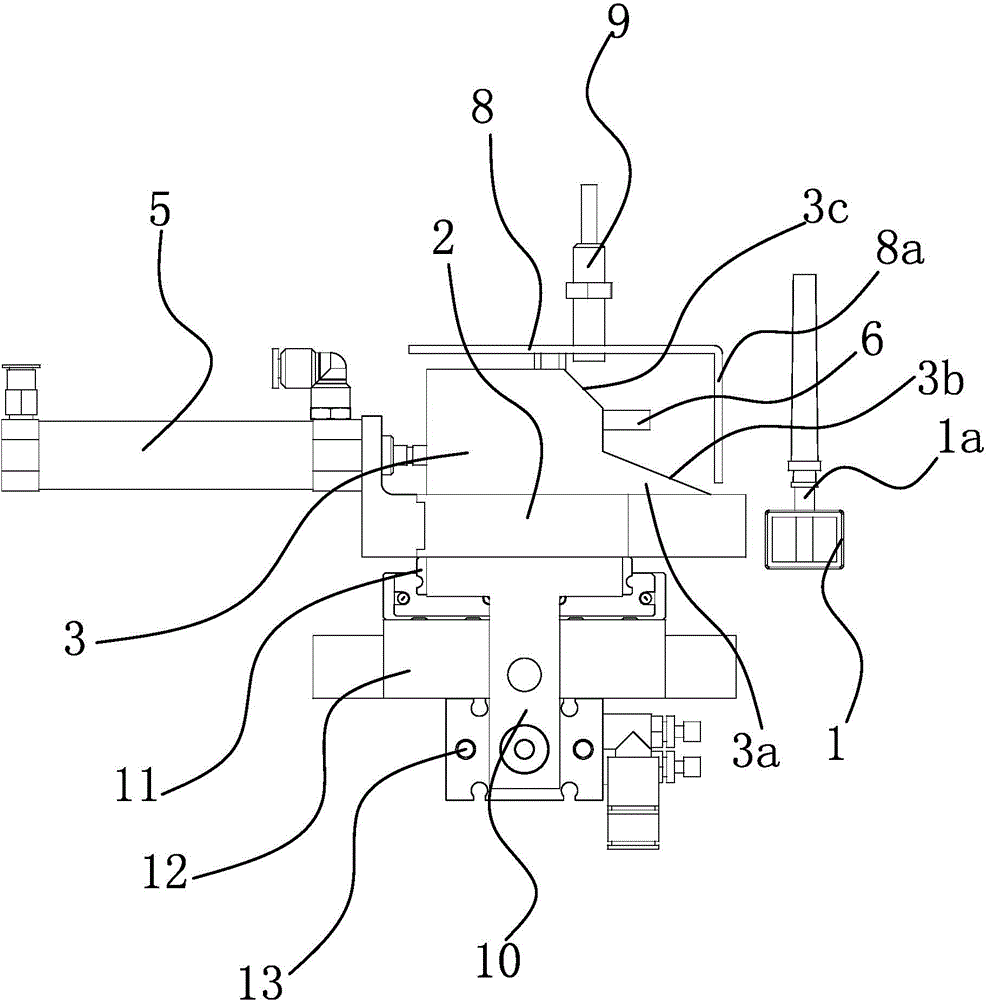

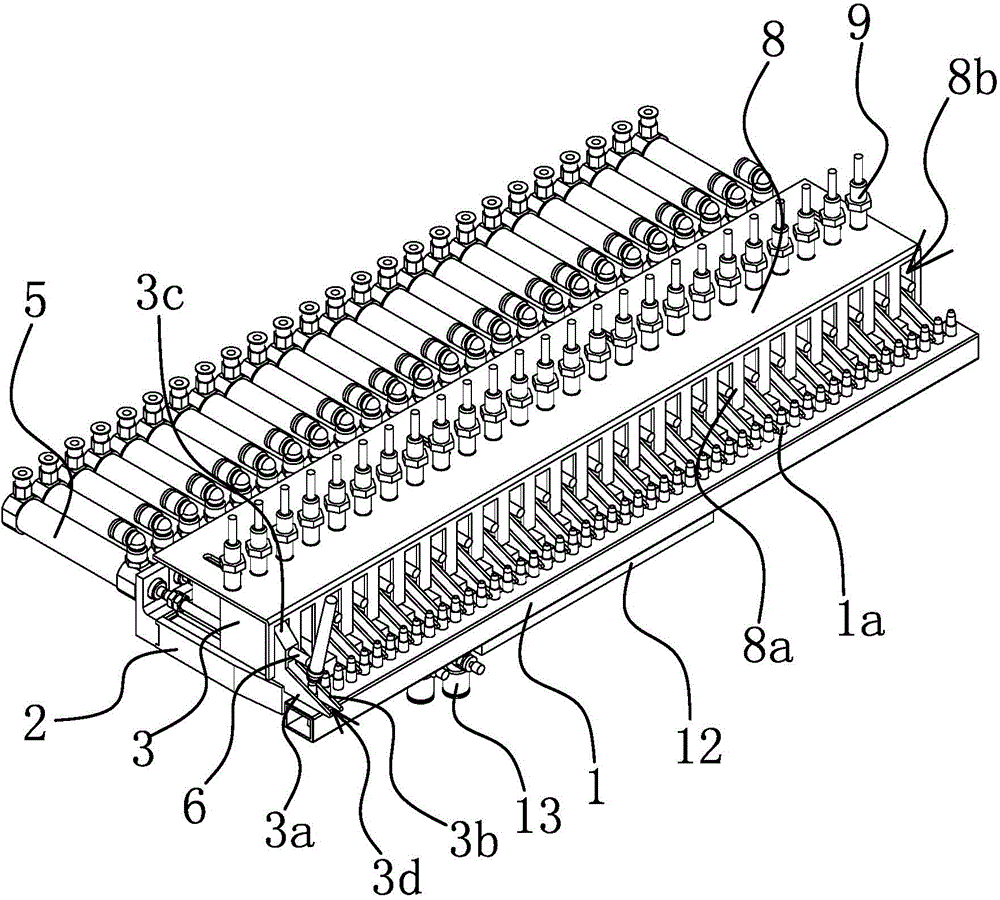

[0032] This blanking device is mainly used for the blanking of injection needles. The medical accessories assembly machine includes a frame, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the unloading device includes a carrier 1 arranged on a frame and a mount 2 located on one side of the carrier 1 , and a material box is arranged on the other side of the carrier 1 . The top of the mounting base 2 is also provided with a fixed plate 8, the fixed plate 8 is arranged horizontally, the carrier 1 is in the shape of a strip, and a number of positioning columns 1a for medical accessories to be socketed and positioned are arranged on the carrier 1 at even intervals, the positioning columns 1a The cross-section is circular, and a number of blanking blocks 3 are evenly spaced on the mounting base 2. The end of the blanking block 3 opposite to the carrier 1 is the front end. Mobile drive source one. Specifically, the driving source one is a plurality of cylinders o...

Embodiment 2

[0041] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the guide structure includes a slide rail arranged on the mounting base 2 along the direction perpendicular to the length of the carrier 1, and a slider is fixed at the bottom of the slider. The slide block is slidably connected on the slide rail.

Embodiment 3

[0043] The structure and principle of this embodiment are basically the same as that of Embodiment 1 and Embodiment 2. The difference is that the drive structure includes a servo motor fixed on the frame, and the output shaft of the servo motor is fixedly connected with a screw mandrel. The length direction of the mounting base 2 is parallel to the length direction of the carrier 1, and a threaded hole is opened on the mounting seat 2, and the screw rod is threaded in the threaded hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com