Flame welding repair machine for industrial kiln and furnace

An industrial furnace and welding repair technology, applied in the direction of gas flame welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of uneven delivery of welding repair materials, low operating efficiency, limited negative pressure force, etc., to improve reliability Control performance, improve welding repair quality, reliable effect of feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

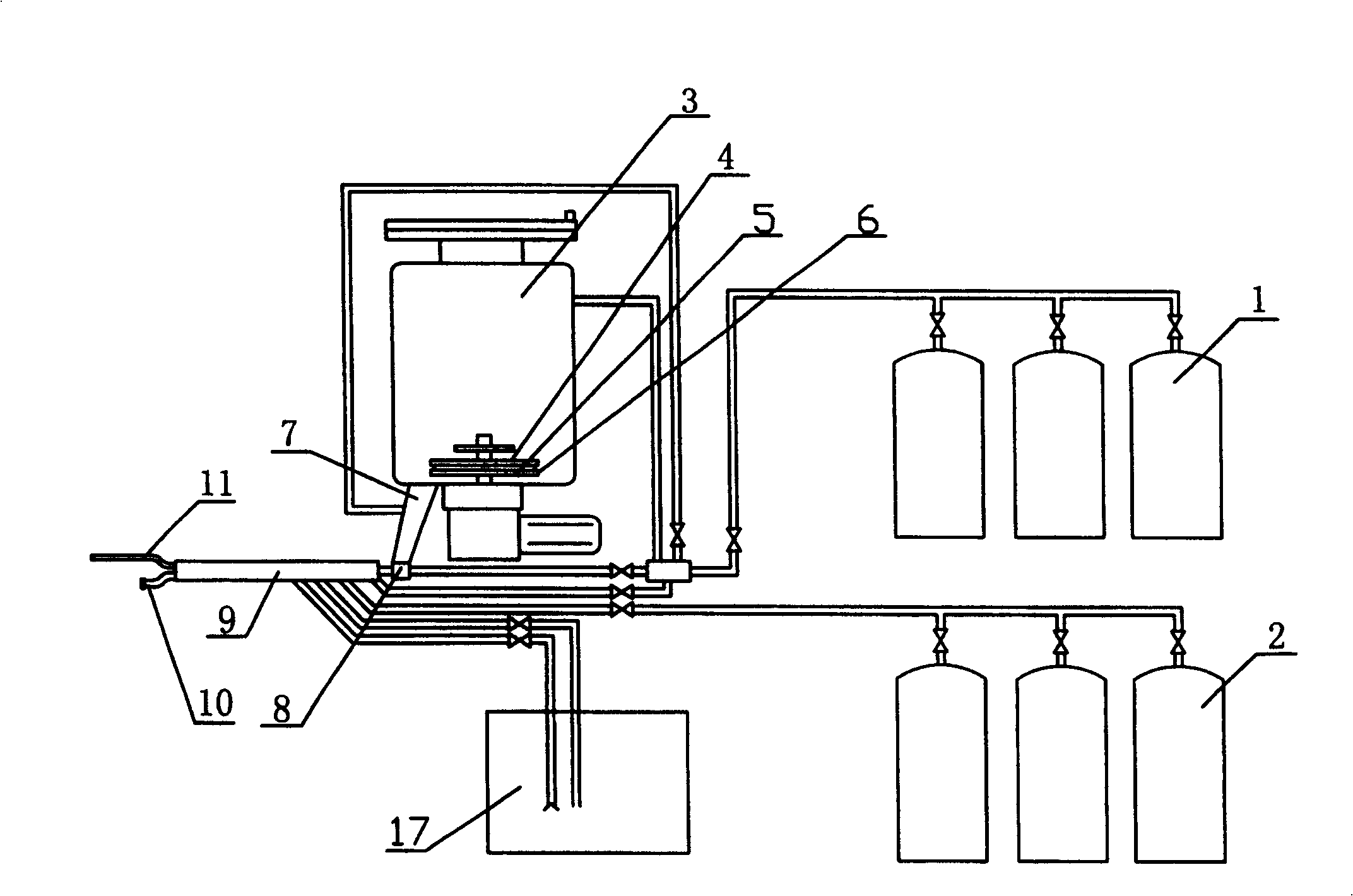

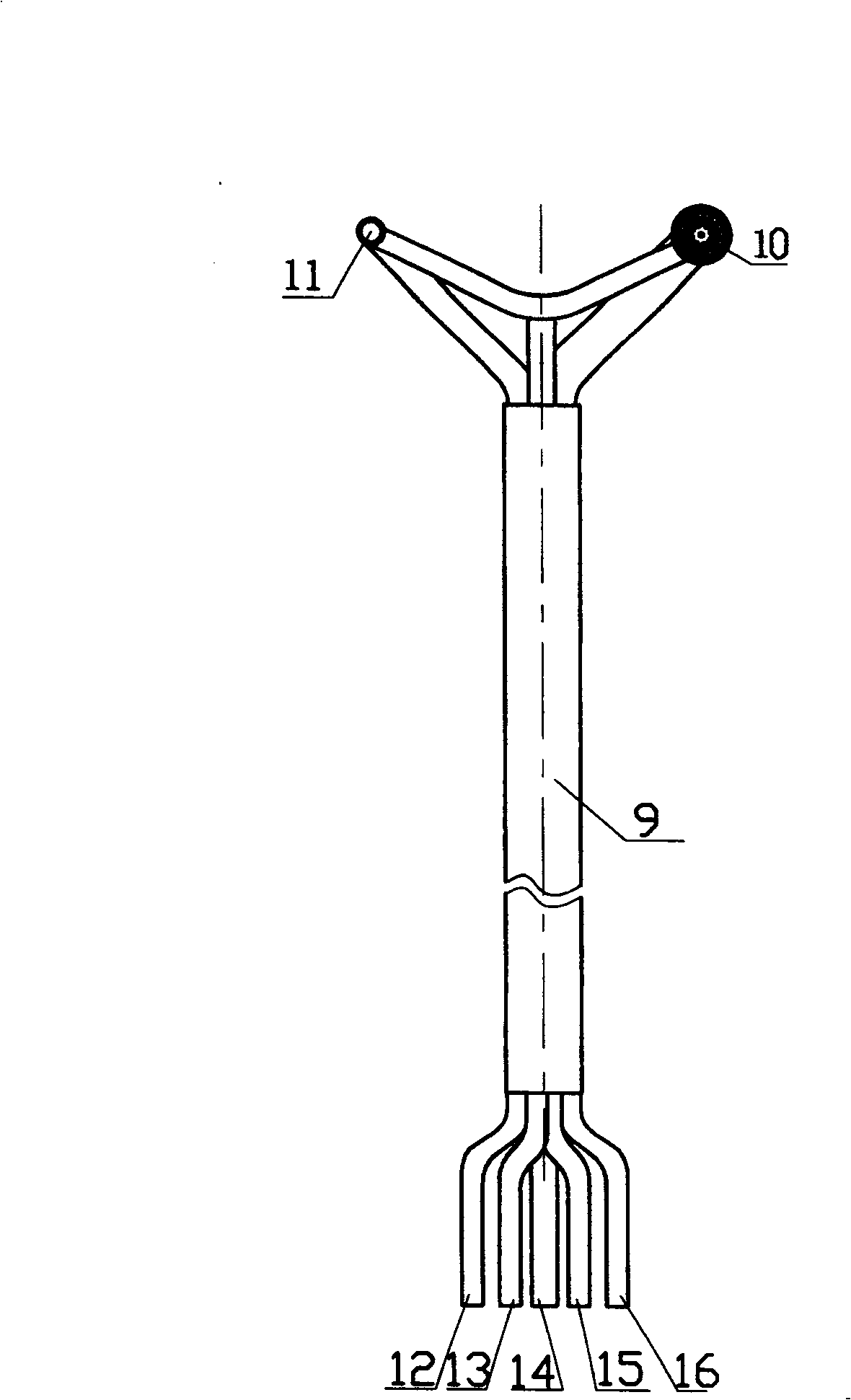

[0021] Such as figure 1 , 2 , shown in 3, industrial furnace flame welding repair machine of the present invention, comprises welding repairing material feeding system, oxygen supply system 1, gas supply system 2, air hammer, trowel, gunning gun 9, control box, is located at The gas outlet, oxygen outlet, gunning material outlet, cooling water inlet and outlet, gas pressure gauge, oxygen pressure gauge, oxygen flow meter, gas flow meter, power supply device, and disc feeder on the control box, the gas can be It is any one or a mixture of two or more of acetylene, propane, methane, propylene, gasoline, and diesel. It is characterized by:

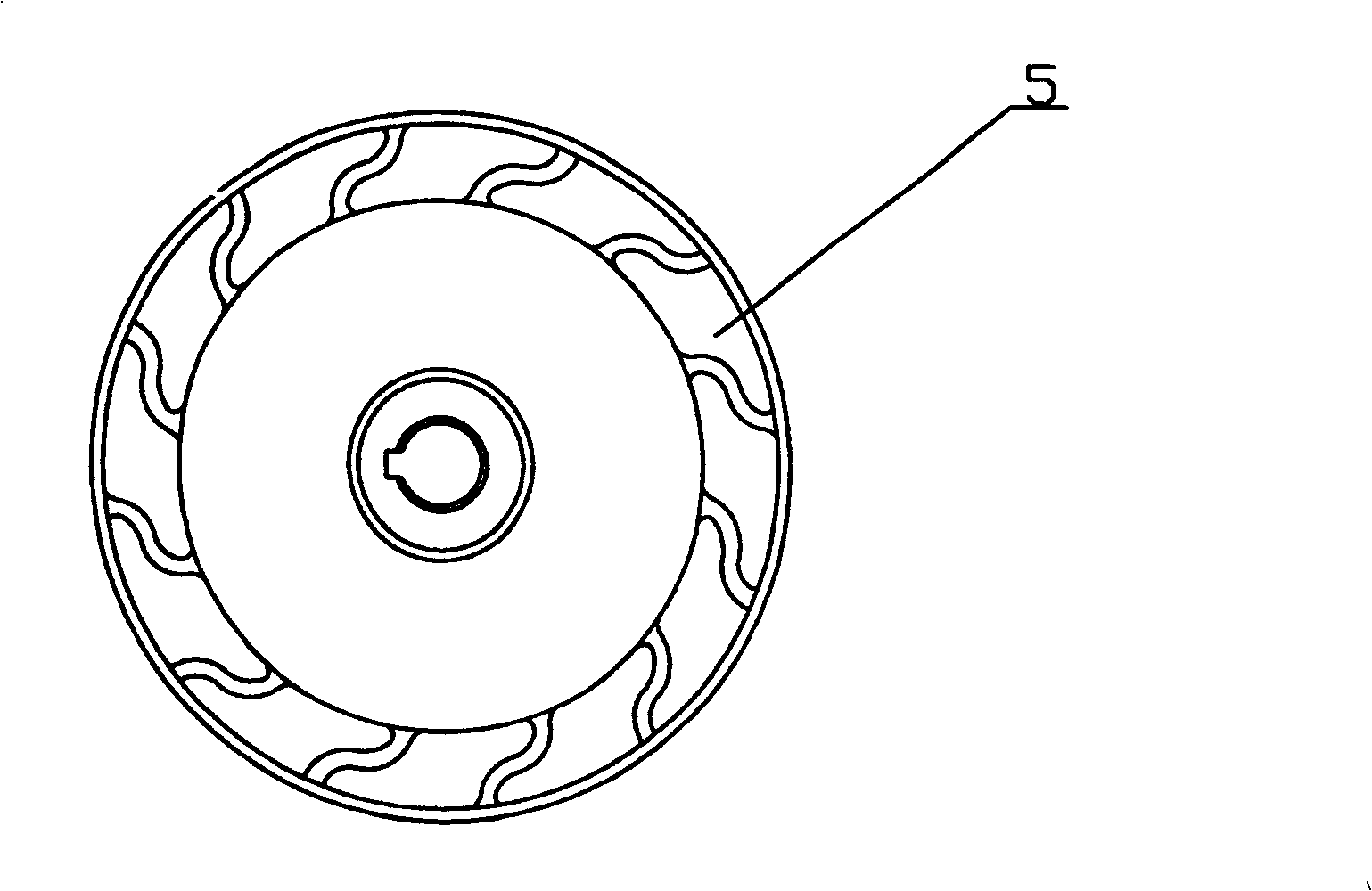

[0022] 1) The disc of the disc feeder is composed of a stirring wheel, an upper feeding tray 4 located under the stirring wheel, a lower feeding tray 6, a middle plate 5 sandwiched between the upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com