Automatic washing type industrial wastewater purification device

An industrial wastewater and automatic flushing technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as waste of manpower and material resources, low efficiency of impurities, and increase of enterprise costs. Achieve the effect of improving filtration efficiency, long working life and reducing enterprise cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

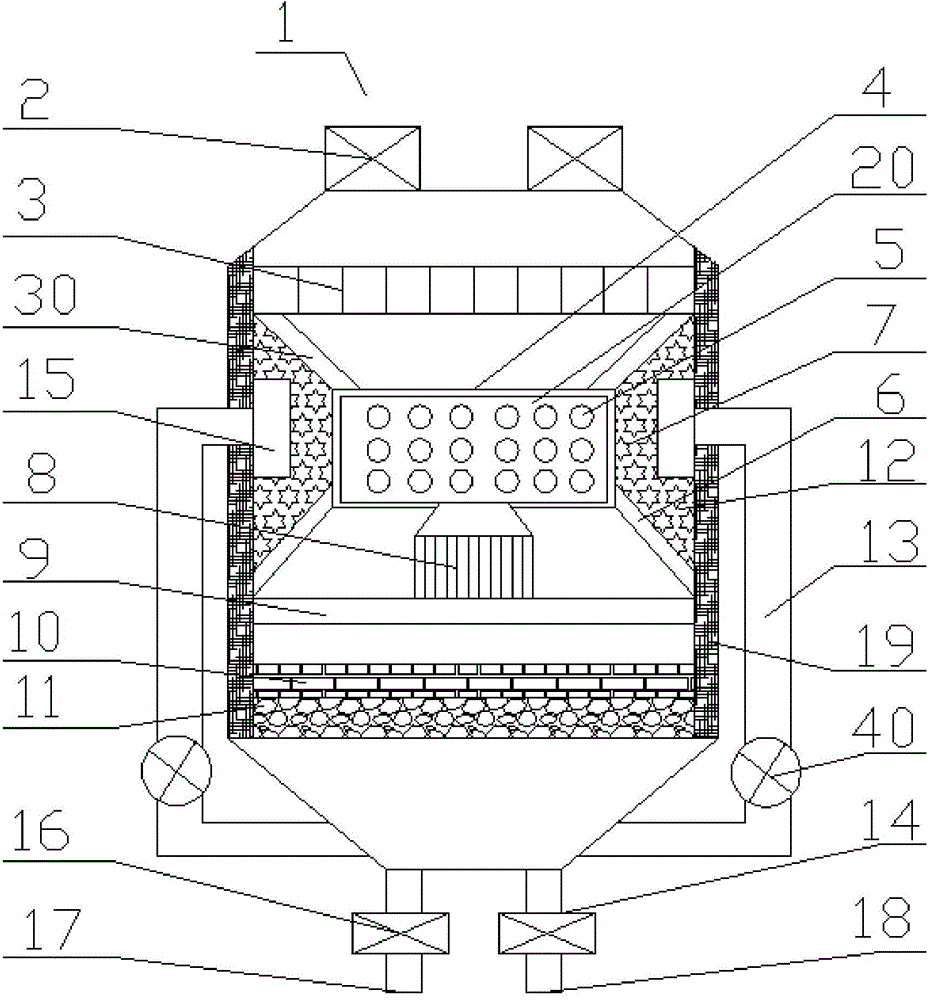

[0028] Such as figure 1 As shown, a kind of automatic flushing type industrial waste water purifying device, it comprises main body 1, and described main body 1 comprises water inlet 2, water outlet 18, frequency conversion motor 8, clean room 12 and conduit 13, is provided with trapezoidal The trapezoidal sewage cavity and the cylindrical body of the body 1 are connected by an open-close or lap joint, and the trapezoidal sewage cavity can be opened or removed when needed, so as to clean up the impurities inside the body 1; in the body 1 The lower end of the body is provided with an inverted trapezoidal water purification chamber, and the water inlet 2 is symmetrically arranged on both sides of the top of the body 1, so that sewage can be added from the two water inlets 2 at the same time, so that the sewage can be evenly distributed from the two water inlets 2 Flowing into the body can improve work efficiency. A number of uniformly arranged drainage plates 3 are arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com