Tooth repair material as well as preparation method and application thereof

A tooth restoration material and reinforced technology, applied in dental preparations, dentistry, dental prosthesis, etc., can solve the problems that cannot meet the mechanical requirements of dental crowns and bridges, and the clinical application of lithium disilicate glass ceramics is not widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

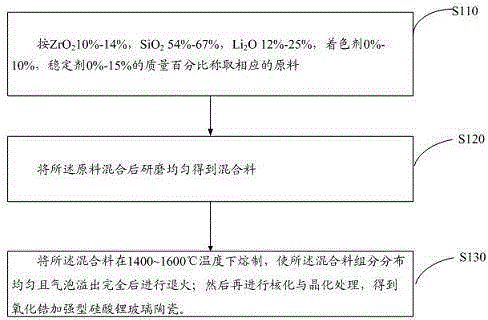

[0021] see figure 1 , the preparation method of the dental restoration material of one embodiment, comprising:

[0022] S110, press ZrO 2 10%-14%, SiO 2 54%-67%, Li 2 O 12%-25%, coloring agent 0%-10%, stabilizer 0%-15% by mass percentage to take corresponding raw materials;

[0023] S120. After mixing the raw materials, grind them uniformly to obtain a mixture.

[0024] Through preliminary grinding, the raw materials of each component are pre-mixed, which is beneficial to the quality of the finished product.

[0025] S130. Melting the mixture at a temperature of 1400-1600° C., so that the components of the mixture are evenly distributed and the air bubbles are completely overflowed, and then annealed; then nucleation and crystallization are performed to obtain zirconia-reinforced silicon lithium oxide glass ceramics.

[0026] In one embodiment, the nucleation and crystallization treatment is as follows: first nucleation at 650-800° C. for 1-9 hours, and then heating up ...

Embodiment 1

[0030] The chemical composition and mass percentage of the tooth restoration material are: ZrO 2 10%, SiO 2 55%, Li 2 O 12%, Eu 2 o 3 10%, SrO13%. Mix the above components and grind them evenly to obtain a mixture

[0031] Melt the mixture at a temperature of 1400°C, so that the components of the mixture are evenly distributed and the air bubbles overflow completely before annealing; first nucleate at 650°C for 9 hours, then raise the temperature to 600°C for crystallization treatment for 20 hours , to obtain zirconia reinforced lithium silicate glass ceramics.

Embodiment 2

[0033] The chemical composition and mass percentage of the tooth restoration material are: ZrO 2 14%, SiO 2 60%, Li 2 O 20%, MnO 2 5%, Y 2 o 3 1%. After mixing the above components, grind them evenly to obtain a mixture;

[0034] Melt the mixture at a temperature of 1500°C so that the components of the mixture are evenly distributed and the air bubbles overflow completely before annealing; first nucleate at 750°C for 5 hours, then raise the temperature to 1000°C for crystallization for 15 hours , to obtain zirconia reinforced lithium silicate glass ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com