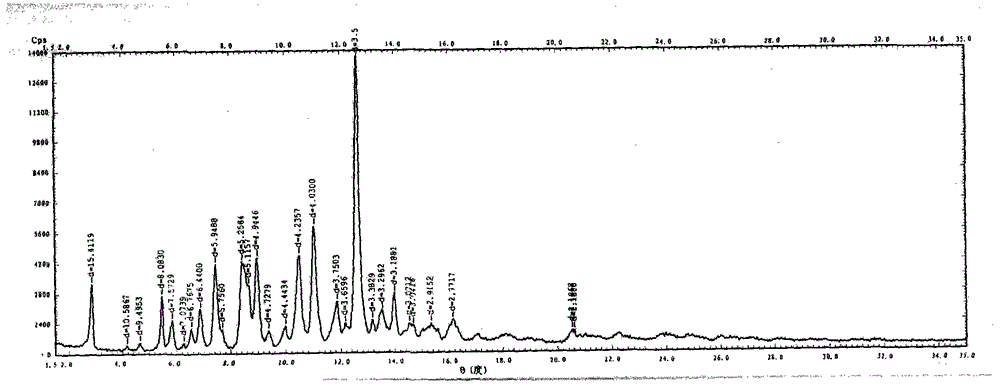

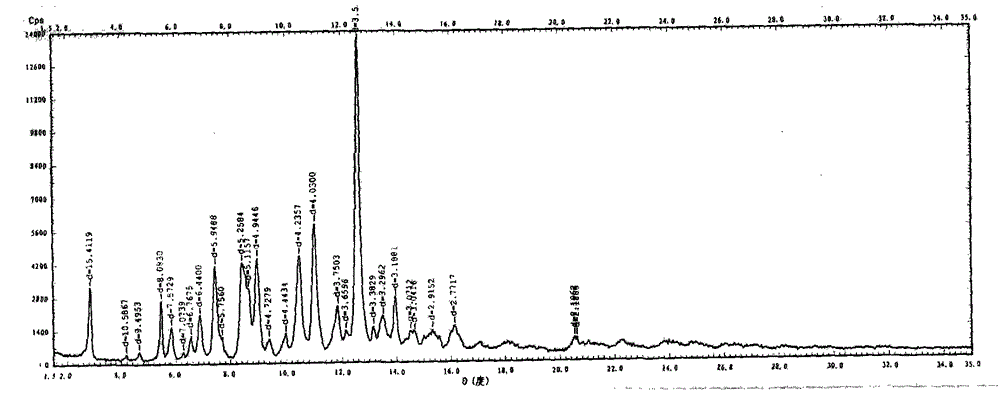

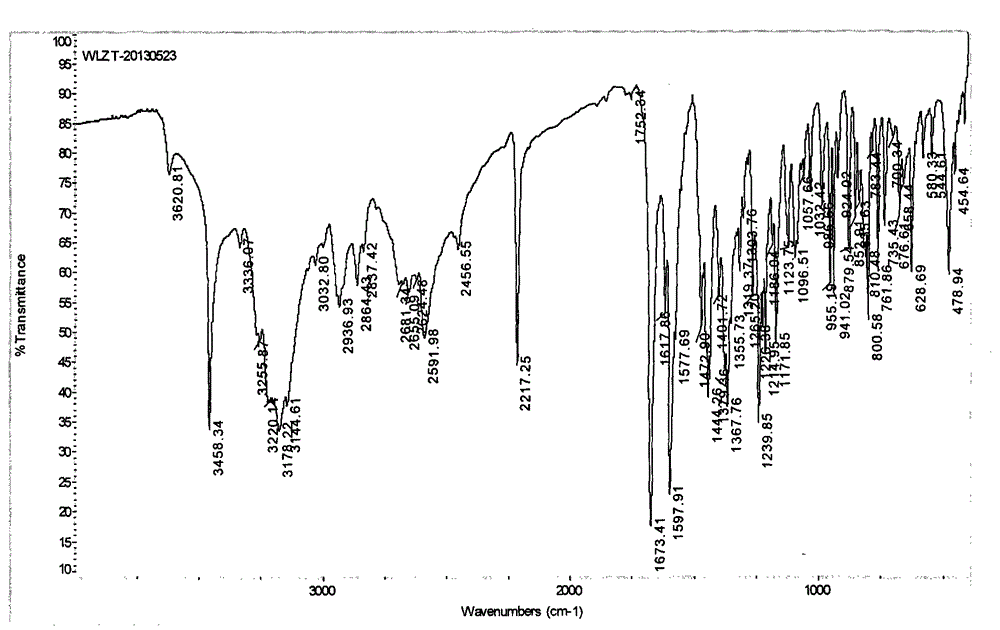

Novel preparation method of III crystal-form vilazodone hydrochloride

A technology of vilazodone and vilazodone hydrochloride, applied in the directions of organic chemistry, organic chemistry, etc., can solve problems such as inability to realize industrialized production, and achieve a shortened process time, good reproducibility, and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve vilazodone (4.41g, 10mmol) in 30mL of tetrahydrofuran, control the temperature at 25°C, slowly add 3mL of 1N HCl, stir for 30 minutes, a white solid precipitates, filter, and vacuum dry at 120°C for 72 hours to obtain hydrochloric acid Vilazodone III crystal form 4.2g, yield 88%.

Embodiment 2

[0024] Dissolve vilazodone (4.41g, 10mmol) in 30mL of tetrahydrofuran, control the temperature at 30°C, slowly add 3mL of 1N HCl, stir for 30 minutes, a white solid precipitates, filter, and vacuum dry at 130°C for 24 hours to obtain hydrochloric acid Vilazodone III crystal form 4.3g, yield 90%.

Embodiment 3

[0026] Dissolve vilazodone (4.41g, 10mmol) in 30mL of tetrahydrofuran, control the temperature at 40°C, slowly add 3mL of 1N HCl, stir for 30 minutes, a white solid precipitates, filter, and vacuum dry at 150°C for 20 hours to obtain hydrochloric acid Vilazodone III crystal form 4.1g, yield 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com