Method for preparing immobilized cellulase

A technology of cellulase and cellulose acetate, which is applied in the direction of fixing on/in the organic carrier, and can solve the problems of poor stability, easy inactivation, denaturation, and easy inactivation of free cellulase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

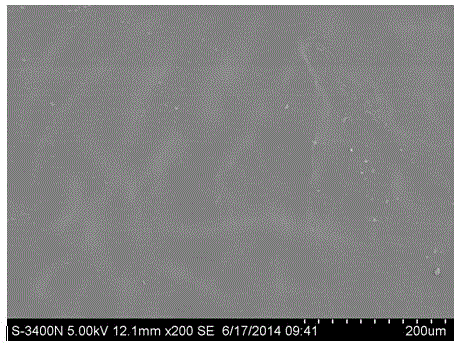

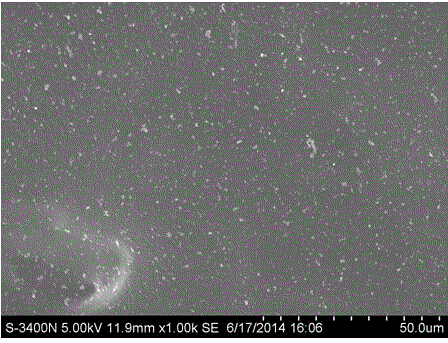

Image

Examples

specific Embodiment approach 1

[0008] Embodiment 1: The method for immobilizing cellulase is realized through the following steps: 1. Preparation of composite membrane: 5 g of cellulose acetate is dissolved in 100 mL of acetone. The prepared polypropylene membrane was soaked in acetone solution dissolved in cellulose acetate to form a film naturally, and the cellulose acetate / polypropylene composite membrane was rinsed with deionized water and dried several times for later use; 2. Enzyme immobilization: the enzyme solution Cellulase with a concentration of 0.5-2.5% and disodium hydrogen phosphate-potassium dihydrogen phosphate buffer are mixed at a pH of 2 to 6, and a cellulose acetate / polypropylene composite film is added. After stirring for 1~5h, add 0.35~0.55% glutaraldehyde for cross-linking reaction for 1~5h, take out the enzyme film and wrap it on the surface of the cylinder to make an immobilized cellulase roll; Activity: The activity of cellulase is 5.103 U / cm 2 , the immobilized cellulase roller c...

specific Embodiment approach 2

[0009] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 2, the concentration of glutaraldehyde is selected to be 0.45-0.55%. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 2, the concentration of glutaraldehyde is selected to be 0.45-0.55%, and the immobilization temperature is 40-50°C. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com