A variable temperature deformation process and subsequent processing method suitable for mg‑gd‑y alloys

A processing method and alloy technology are applied in the field of industrial magnesium alloys, which can solve the problems of less application of magnesium alloys, and achieve the effects of solving incomplete deformation and improving recrystallization ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

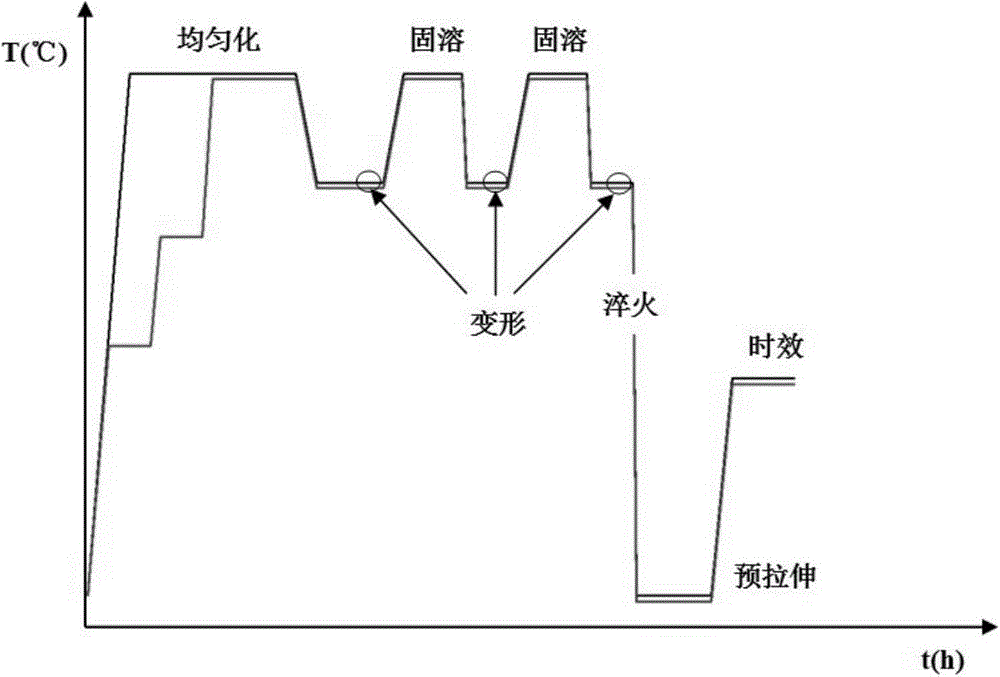

[0058] Embodiment 1 Diameter is the Mg-7Gd-5Y-1.5Nd-0.6Zr alloy deformation and subsequent processing method of 500mm

[0059] Homogenization treatment: heat the alloy ingot to 420°C and keep it for 6h; then raise the temperature to 500°C and keep it for 10h; continue to heat up to 540°C and keep it for 40h. Alloy cooling treatment: lower the alloy temperature to 500°C and keep it warm for 8 hours. Alloy deformation: The deformation method is direct extrusion after three-way forging. Alloy heating and solid solution: the alloy is heated to 530°C and kept for 10 hours. Alloy cooling treatment: cooling the alloy to 520°C and keeping it warm for 8 hours. Alloy deformation: the alloy is deformed again, and the deformation method is rolling. Subsequent processing method: Alloy quenching and water-cooling the rolled plate immediately, pre-stretch the plate by 2% by volume to eliminate residual stress, and then age the alloy at 220°C for 8 hours.

[0060] The implementation of th...

Embodiment 2

[0061] Embodiment 2 The deformation and follow-up processing method of Mg-8Gd-3Y-1Zn-0.6Zr alloy with a diameter of 200mm

[0062] Homogenization treatment: heat the alloy to 530°C and keep it warm for 24h. Alloy cooling treatment: lower the alloy temperature to 500°C and keep it warm for 10h. Alloy deformation: The alloy deformation method is rolling after extrusion. Alloy heating and solid solution: the alloy is heated to 530°C and kept for 4 hours. Alloy cooling treatment: cool the Mg-Gd-Y alloy to 500°C and keep it warm for 10 hours. The alloy continues to deform: the deformation method is rolling. Subsequent processing method: Quenching and water-cooling the deformed horse alloy, pre-stretching 3% to eliminate residual stress, and then aging the alloy at 225°C for 24h.

[0063] The implementation of the present invention can effectively improve the recrystallization ability of the alloy, the grain size after deformation is 5-10 μm, the fracture strength can reach up t...

Embodiment 3

[0064] Embodiment 3 The deformation and subsequent processing method of Mg-9Gd-4Y-2Zn-0.5Zr alloy with a diameter of 300mm

[0065] Homogenization treatment: heat the alloy to 535°C for 36h. Alloy cooling treatment: lower the alloy temperature to 520°C and keep it warm for 12h. Alloy deformation: The deformation method is rolling after extrusion. Alloy heating and solid solution: the alloy is heated to 530°C and kept for 4 hours. Subsequent processing method: immediately quench and water-cool the alloy after solid solution, pre-stretch 2% to eliminate residual stress, and then age the alloy at 240°C for 18 hours.

[0066] The implementation of the invention can effectively improve the alloy strength and weaken the alloy texture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com