Novel structural cadmium telluride thin-film battery and preparation method thereof

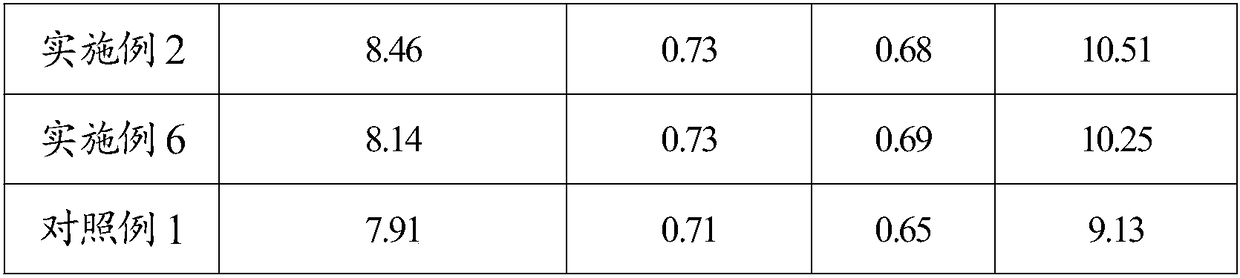

A technology of thin-film battery and new structure, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of affecting light energy, reducing the light transmittance of FTO substrates, affecting material properties, etc., to achieve improved uniformity and superior photoelectric performance , the effect of improving the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

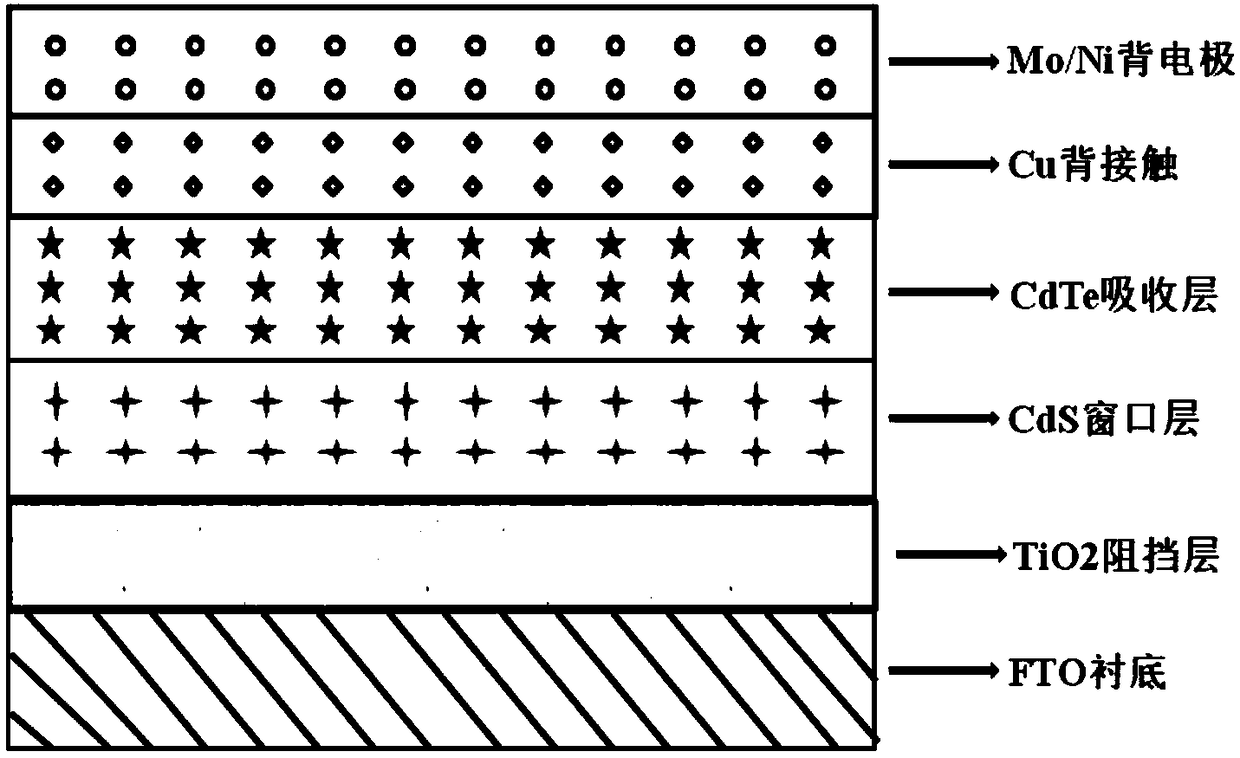

[0029] Such as figure 1 As shown, a new structure of cadmium telluride thin film battery is provided with FTO conductive glass substrate layer, TiO 2 Barrier layer, cadmium sulfide window layer, cadmium telluride light absorbing layer, Cu back contact layer and molybdenum nickel composite back electrode layer. Among them, the thickness of the conductive film in the substrate layer is 50nm, TiO 2 The thickness of the barrier layer is 200nm, the thickness of the cadmium sulfide window layer is 200nm, the thickness of the cadmium telluride light absorption layer is 2μm, the thickness of the Cu back contact layer is 50nm, and the thickness of the molybdenum nickel composite back electrode layer is 200nm.

[0030] The preparation method of the above-mentioned cadmium telluride solar cell comprises the following steps:

[0031] (1) Use FTO conductive glass as the substrate material, cut it into a size of 2cm×2cm, use ultrasonic cleaning method, clean it with absolute ethanol solut...

Embodiment 2

[0041] Such as figure 1 As shown, a new structure of cadmium telluride thin film battery is provided with FTO conductive glass substrate layer, TiO 2 Barrier layer, cadmium sulfide window layer, cadmium telluride light absorbing layer, Cu back contact layer and molybdenum nickel composite back electrode layer. Among them, the thickness of the conductive film in the substrate layer is 100nm, TiO 2 The thickness of the blocking layer is 300nm, the thickness of the cadmium sulfide window layer is 250nm, the thickness of the cadmium telluride light absorbing layer is 3μm, the thickness of the Cu back contact layer is 100nm, and the thickness of the molybdenum nickel composite back electrode layer is 300nm.

[0042] The preparation method of the above-mentioned cadmium telluride solar cell comprises the following steps:

[0043] (1) Use FTO conductive glass as the substrate material, cut it into a size of 2cm×2cm, use ultrasonic cleaning method, clean it with absolute ethanol sol...

Embodiment 3

[0053] Such as figure 1 As shown, a new structure of cadmium telluride thin film battery is provided with FTO conductive glass substrate layer, TiO 2 Barrier layer, cadmium sulfide window layer, cadmium telluride light absorbing layer, Cu back contact layer and molybdenum nickel composite back electrode layer. Among them, the thickness of the conductive film in the substrate layer is 150nm, TiO 2 The thickness of the barrier layer is 400nm, the thickness of the cadmium sulfide window layer is 300nm, the thickness of the cadmium telluride light absorption layer is 4μm, the thickness of the Cu back contact layer is 150nm, and the thickness of the molybdenum nickel composite back electrode layer is 400nm.

[0054] The preparation method of the above-mentioned cadmium telluride solar cell comprises the following steps:

[0055] (1) Use FTO conductive glass as the substrate material, cut it into a size of 2cm×2cm, use ultrasonic cleaning method, clean it with absolute ethanol sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com