A kind of color-preserving processing method of natural colored silk

A technology of colored silk and processing methods, which is applied in the fields of dyeing, textiles and papermaking, etc., can solve problems such as general effect, complicated process, unfavorable industrialized production, etc., and achieve high color depth and K/S value and high color retention rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

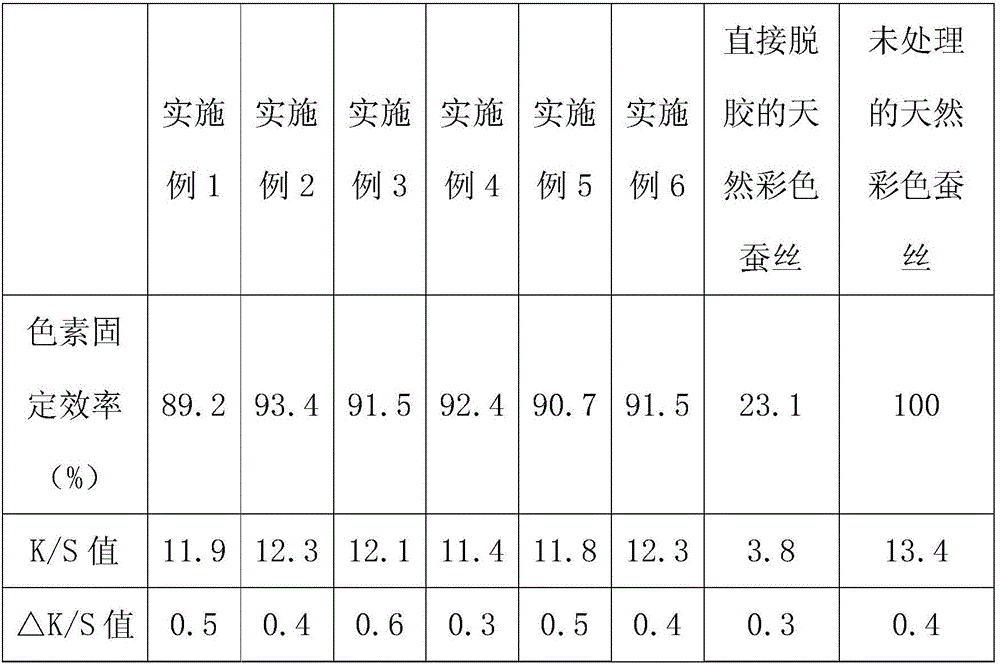

Examples

Embodiment 1

[0017] (1) Swelling: remove impurities from the natural colored silk, let it sit in warm water at 35°C for 20 minutes, and take it out after swelling occurs on the surface of the natural colored silk.

[0018] (2) Pigment adsorption and transfer: immerse the swollen natural colored silk in a nano-color fixing agent with a mass fraction of 2% nano-scale pigment adsorbent and 1.5% cross-linking agent EH, vibrate at 45°C for 30 minutes, and take it out. Wash with deionized water and steam at 80°C for 30 minutes.

[0019] (3) Degumming and pigment fixation: After degumming at 90°C to remove excess sericin on the surface of natural colored silk, immerse in the pigment fixative solution, soak at a constant temperature of 75°C for color fixation, wash once at 25°C, and dry at 60°C When the water content of natural silk is 25%, natural colored silk with color retention is obtained.

Embodiment 2

[0021] (1) Swelling: remove impurities from the natural colored silk, and soak it in warm water at 40°C for 10 minutes until the surface of the natural colored silk swells, then take it out.

[0022] (2) Pigment adsorption and transfer: immerse the swollen natural colored silk in a nano-color fixing agent with a mass fraction of 2% nano-scale pigment adsorbent and 1.5% cross-linking agent EH, shake at 45°C for 60 minutes at low temperature, and take it out. Wash with deionized water and steam at 100°C for 20 minutes.

[0023] (3) Degumming and pigment fixation: After degumming at 80°C to remove excess sericin on the surface of natural colored silk, immerse in the pigment fixative solution, soak at a constant temperature of 65°C for color fixation, wash twice at 25°C, and dry at 60°C When the water content of natural silk is 25%, natural colored silk with color retention is obtained.

Embodiment 3

[0025] (1) Swelling: Remove impurities from the natural colored silk, let it sit in warm water at 40°C for 20 minutes, and take it out after the surface of the natural colored silk swells.

[0026] (2) Pigment adsorption and transfer: immerse the swollen natural colored silk in a nano-color fixing agent with a mass fraction of 2% nano-scale pigment adsorbent and 1.5% cross-linking agent EH, shake at 45°C for 60 minutes at low temperature, and take it out. Wash with deionized water and steam at 100°C for 30 minutes.

[0027] (3) Degumming and pigment fixation: After degumming at 90°C to remove excess sericin on the surface of natural colored silk, immerse in the pigment fixative solution, soak at a constant temperature of 75°C for color fixation, wash once at 25°C, and dry at 60°C When the water content of natural silk is 25%, natural colored silk with color retention is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com