Processing equipment for reshaping rail head profiles

A contour processing and reshaping technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of high equipment maintenance cost, complex structure, affecting the smoothness and accuracy of rails, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

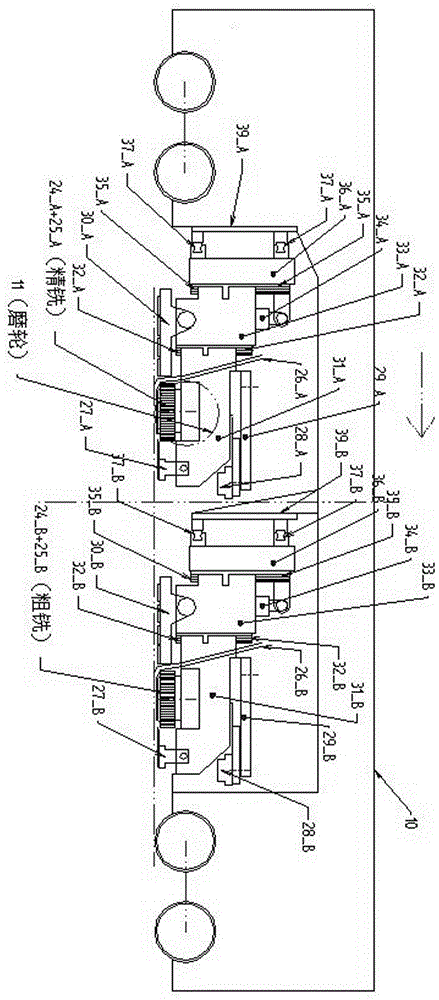

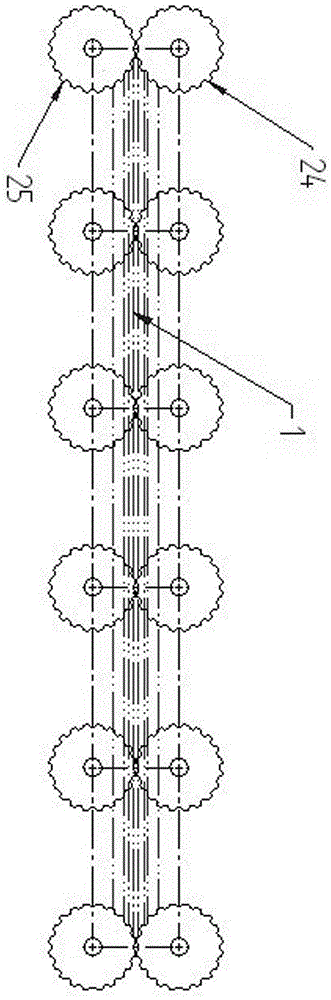

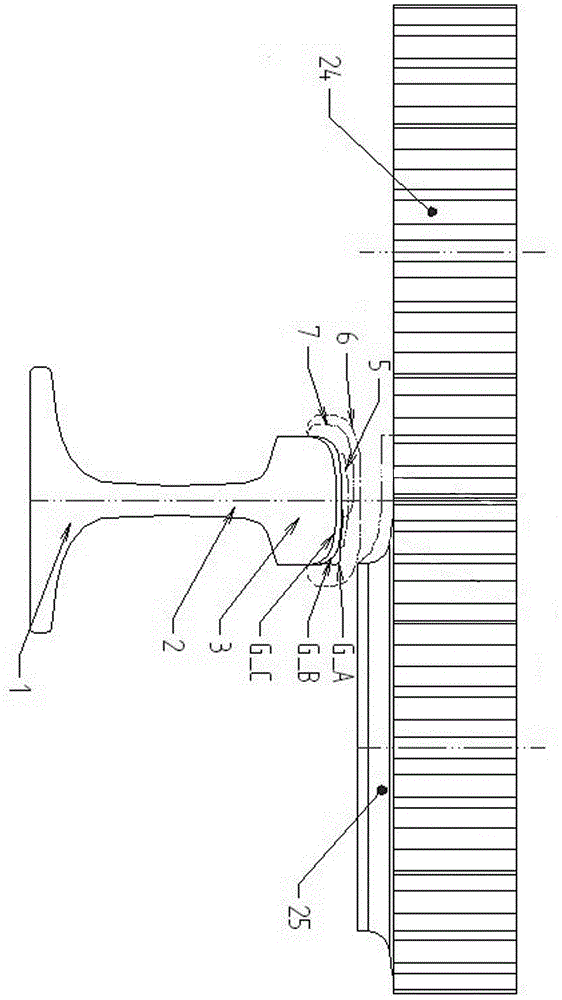

[0098] Example 1.1: Figure 1-Figure 5 They are respectively a structural schematic diagram of a preferred embodiment of the reshaped rail head profile processing equipment described in the first aspect of the present invention, the milling assembly in this embodiment, the meshing relationship between the milling assembly and the rail, the enlarged structure of the milling assembly, the milling assembly and The schematic diagram of the relative positions of the rails. In this embodiment, a reshaped rail head profile processing equipment includes rough milling equipment and fine milling equipment. The rough milling equipment is arranged in front of the advancing direction of the rail, and the rough milling equipment is arranged at Rear along the direction of advance of the rail.

[0099] In this embodiment, the rough milling equipment and the fine milling equipment are installed in the running device 10, so that the running device 10 can perform rough milling and finishing mill...

Embodiment 12

[0115] Embodiment 1.2, a reshaped rail head contour processing equipment, is the same as Embodiment 3.1, the difference is: the milling main unit 31_A lower part is equipped with a grinding drive device, the grinding drive device is connected to the grinding unit, the grinding The unit is used for fine grinding of rails.

[0116] In the above embodiment, the reshaping rail head profile processing equipment can respectively trim the rail profiles on the left and right sides or simultaneously trim the track profiles of the left and right rails in one pass; and the two sets of meshing milling cutters form The front and back of the equipment are arranged on the formed railway line, and the rough machining and finishing of the rail can be realized in one pass to meet the operation requirements of the railway line. The support base 39_B, 39_A is used to support the Y direction moving base 36_B, 36_A, and the moving base realizes the Y direction feed motion through the moving guide r...

Embodiment 21

[0119] Embodiment 2.1: a kind of processing method of reshaping rail head profile, it comprises the following steps:

[0120] a 1 .Arrange two sets of meshing milling cutter heads longitudinally along a single rail;

[0121] b 1 .Longitudinal arrangement of a group of meshing forming milling cutters I along the single rail in front of the reshaping rail head profile processing equipment running direction;

[0122] c 1 . A group of meshing and forming milling cutters II are longitudinally arranged along the single rail behind the running direction of the reshaping rail head profile processing equipment;

[0123] d 1 .Feed the meshing forming milling cutter disc Ⅰ to the rail head, roughing the profile of the rail head;

[0124] e 1 .Feed the meshing forming milling cutter disc II to the rail head to finish the profile of the rail head, thereby improving the smoothness of the processed rail surface;

[0125] f 1 .Reshaping rail head profile processing equipment advances ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com