Method for constructing external walls

A construction method and exterior wall technology, applied to walls, building components, buildings, etc., can solve problems such as inability to ensure that holes are fully filled, holes are not sealed tightly, and hidden dangers of water seepage in large exterior walls, achieving good prospects for popularization and application. Waterproof effect, achieve the effect of standardized construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] Referring to accompanying drawing, a kind of exterior wall construction method comprises the steps:

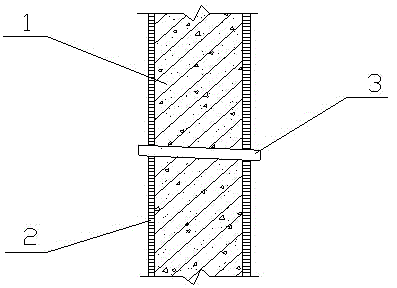

[0025] 1) Set the pouring formwork 2 on both sides of the shear wall 1 to be poured, use the pair of drawing rods 3 to connect the pouring formwork 2 on both sides into a whole, and reinforce the formwork;

[0026] 2) Concrete is poured between the pouring formwork 2 on both sides, and the shear wall 1 is obtained after the concrete is poured, and then the pair of drawing rods 3 and the pouring formwork 2 on both sides are removed in turn, and the pair of drawing wires is removed on the shear wall 1 at this time The position of the rod 3 leaves a hole through the indoor and outdoor;

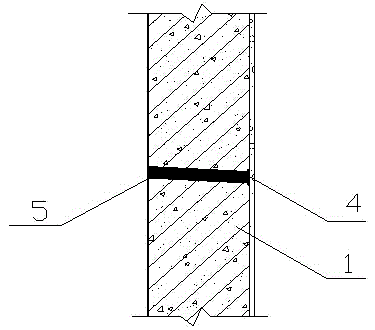

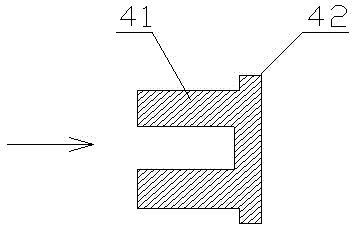

[0027] 3)) Select the appropriate rubber plug 4 according to the size of the hole, and use the rubber plug 4 to block the opening end of the hole outside before the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com