Tunnel secondary lining construction formwork trolley based on rectangular supports

A technology of rectangular support and formwork trolley, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc. It can solve the problems of easy inward deformation of side walls, unreasonable side wall support, mold running and floating, etc., so as to avoid cross operations Mutual interference, meet the needs of vehicles, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

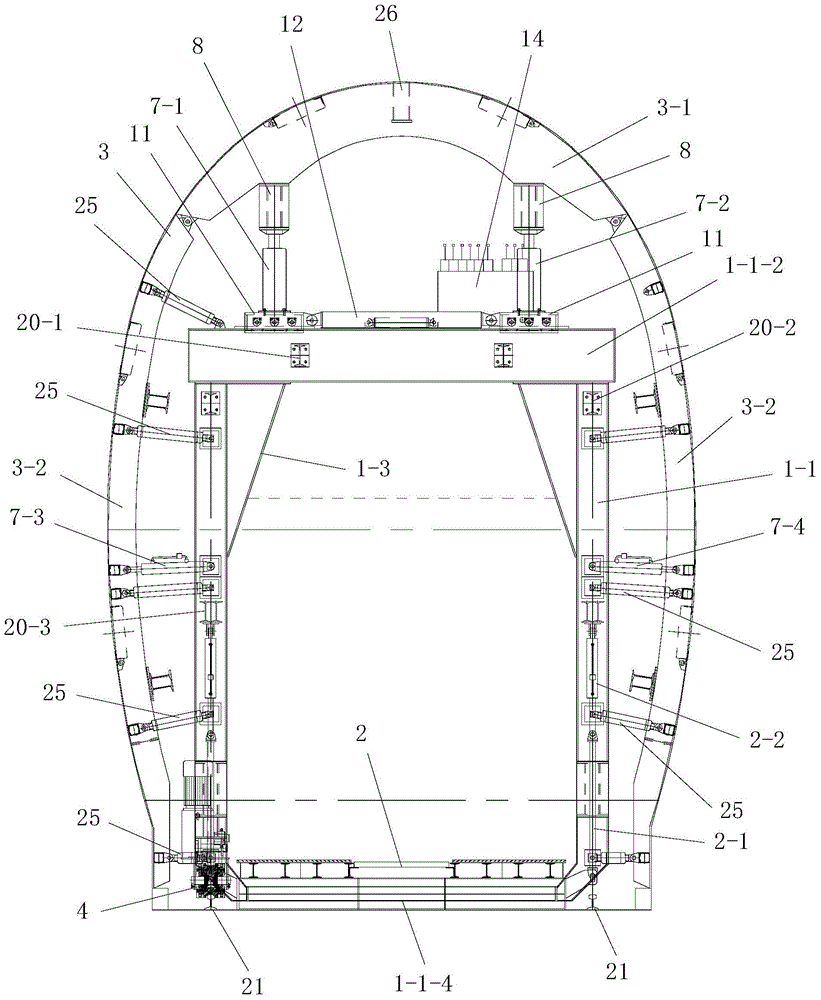

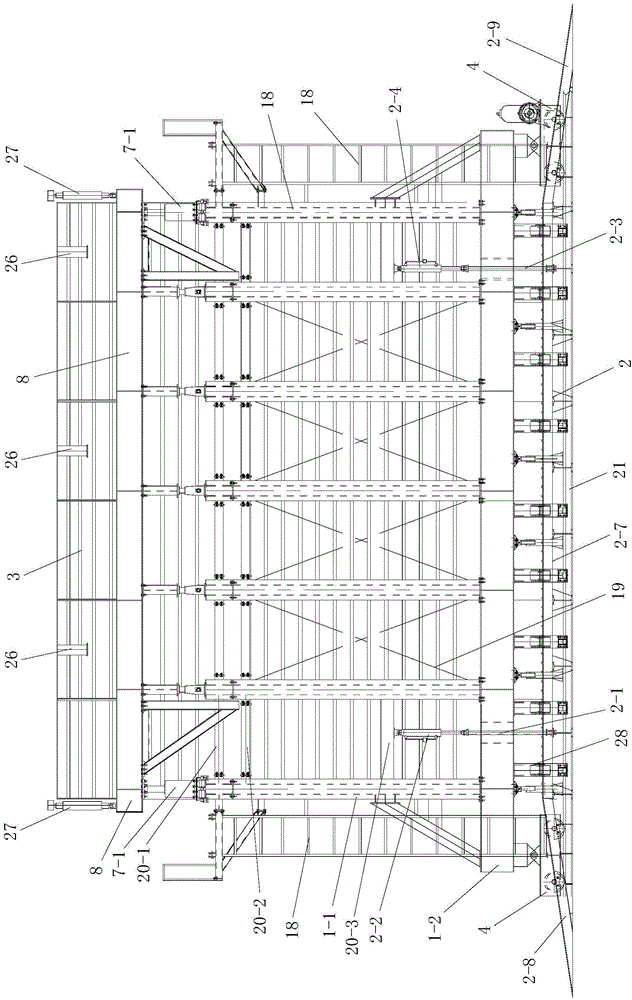

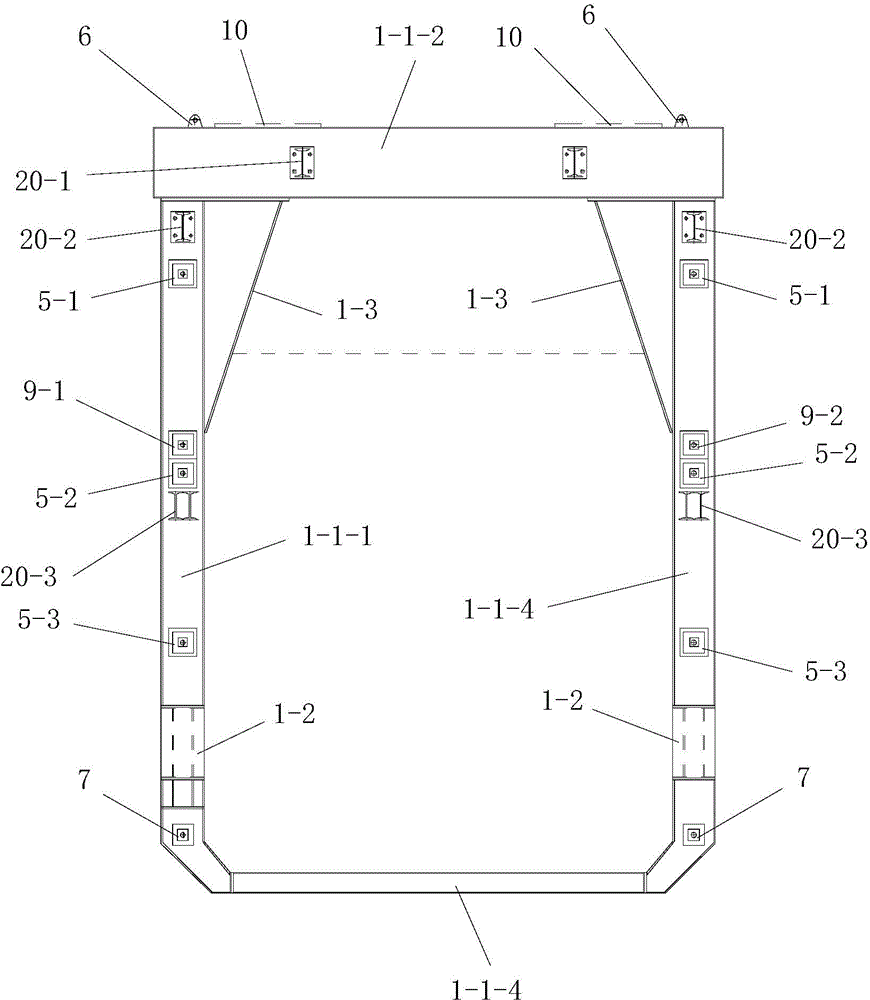

[0069] Such as figure 1 , figure 2 As shown, the present invention includes a rectangular support frame and a trestle assembly 2 located at the bottom of the rectangular support frame, and a formwork support system is provided outside the rectangular support frame to support the formwork assembly 3 for the second lining of the tunnel. The rectangular supporting frame is connected with the trestle assembly 2 as a whole.

[0070] The rectangular support frame includes two left and right walking beams 1-2 arranged on the same plane, a plurality of rectangular supports 1-1 all installed on the two walking beams 1-2 and connected to a plurality of the rectangular supports 1-2. The longitudinal connection structure between the supports 1-1, a plurality of the rectangular supports 1-1 are connected as a whole through the two walking beams 1-2 and the longitudinal connection structure, and the longitudinal connection structure includes multiple channels along the The longitudinal c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal length | aaaaa | aaaaa |

| Horizontal width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com