Special tube part jointing structure, jointing method, and special tube joint

A joint structure and joint method technology, applied in the direction of slender elements, building elements, etc., can solve the problems of inability to apply welded joints, difficult degrees of freedom of joints, and influence on dimensional accuracy, so as to improve structural rigidity and reduce interfacial corrosion , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described below with reference to the accompanying drawings.

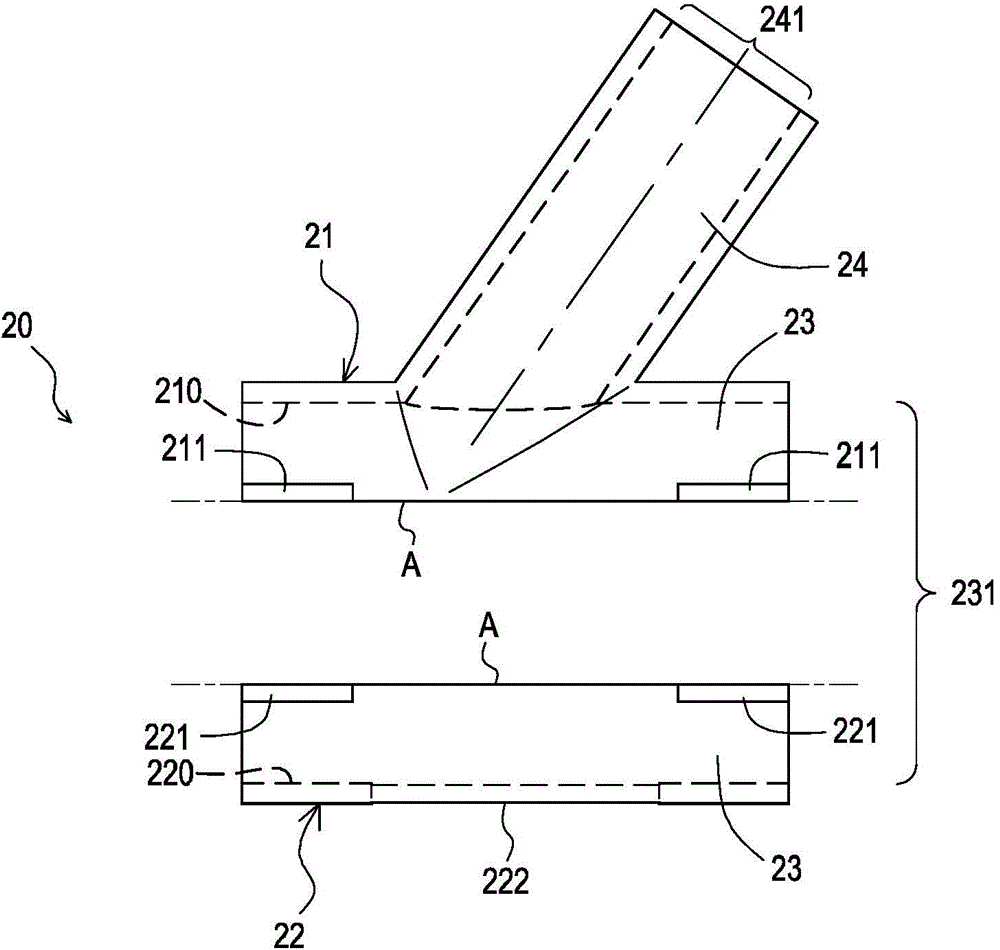

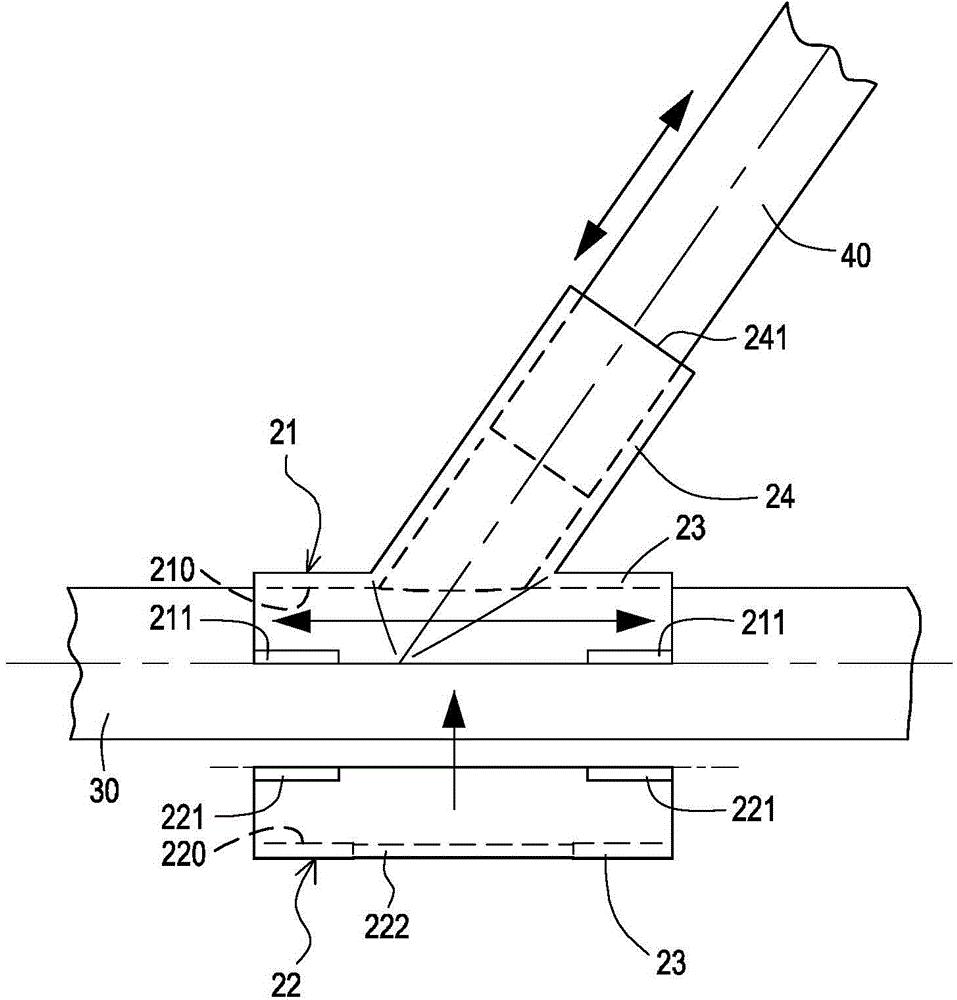

[0038] Such as figure 2 The illustrated front exploded view of the heterogeneous pipe joint of the present invention is shown. The different-material pipe joint 20 in this embodiment includes an upper joint body 21 and a lower joint body 22 . The upper joint body 21 is made of a first metal material (such as steel), and the lower joint body 22 is made of a second metal material (such as aluminum alloy) different from the first metal material. The bottom of the upper joint body 21 is a groove body 210 with a concave surface, the top of the lower joint body 22 is a groove body 220 with a concave surface, the upper joint body 21 and the lower joint body 22, Butt up and down to jointly define a first pipe body 23 and first nozzles 231 at both ends of the first pipe body 23, the upper joint pipe body 21 and the lower joint pipe body 22 are respectively at their pre-join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com