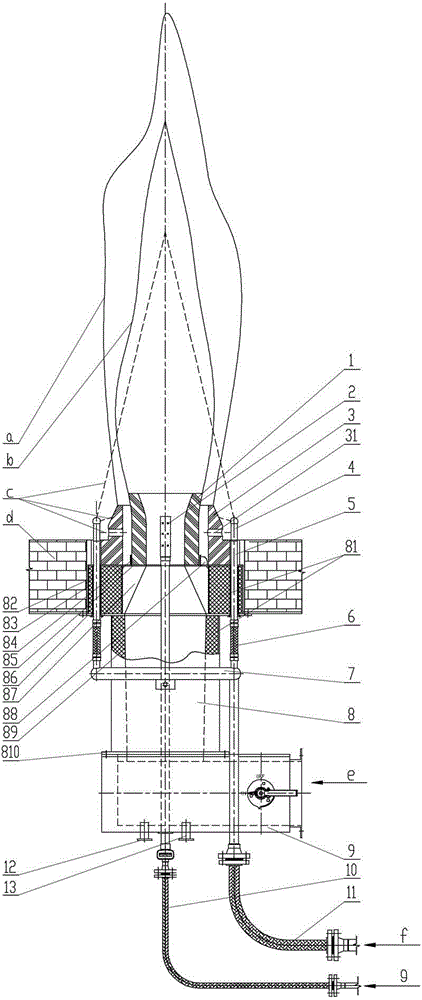

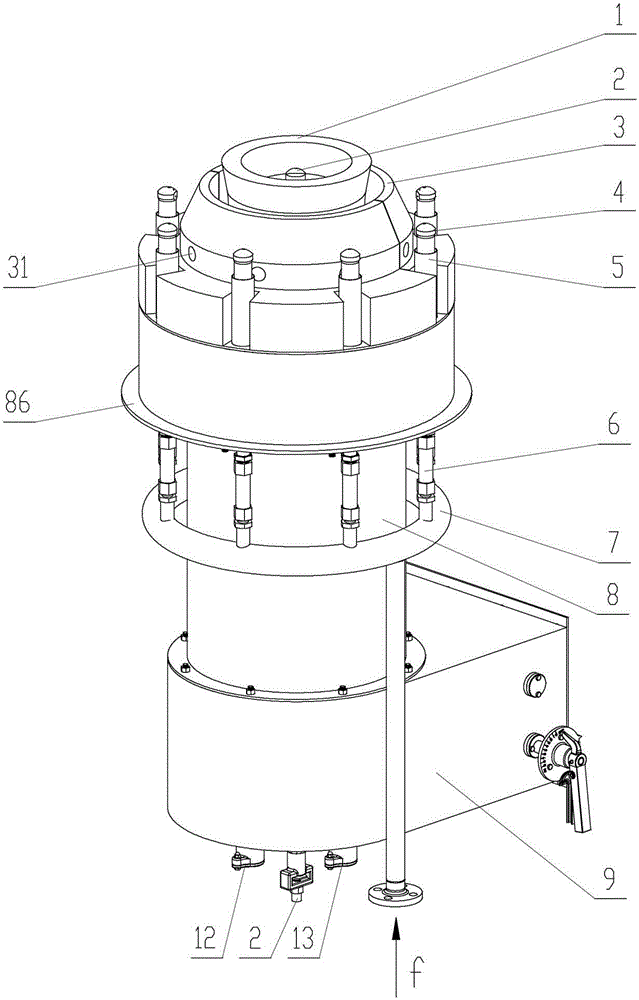

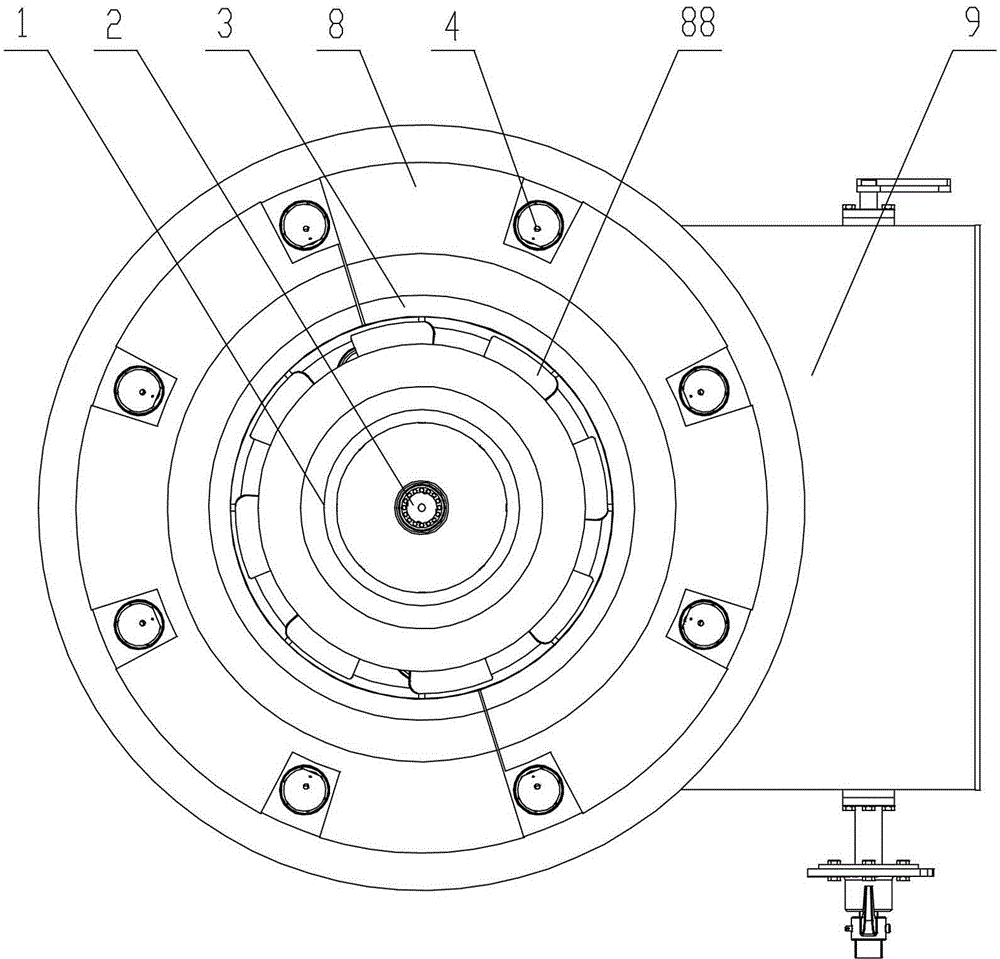

Bottom-mounted type NOx discharging circular flame gas burner

A gas burner and bottom-mounted technology, applied in the directions of gas fuel burners, burners, combustion methods, etc., can solve the problems of flame licking the furnace tube, secondary combustion of heating furnace hearth, fluttering, etc., to suppress NOx generation, realize Effects of NOx emission and low NOx emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The combustion air of the present invention realizes graded supply, that is, constitutes a swirl primary air channel and a direct jet secondary air channel; gas realizes three-stage supply, that is, the first fuel injection port corresponding to the gas through hole of the outer brazier brick, and the upper part of the outer wall of the outer brazier brick. The second fuel injection port, and the third fuel injection port above the corresponding inner brazier brick. At the same time, the mouth of the inner brazier brick is higher than the outer brazier brick, forming a certain height difference, which provides support for the realization of multi-stage and multi-flow field combustion. In the annular air passage between the inner brazier brick and the outer brazier brick for combustion-supporting air and combustion fuel, the primary wind forms a swirling flow, and realizes oxygen-poor and over-rich combustion in the annular air passage; further oxygen-poor oxygen is reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com