Tunable cascading micro-ring filter

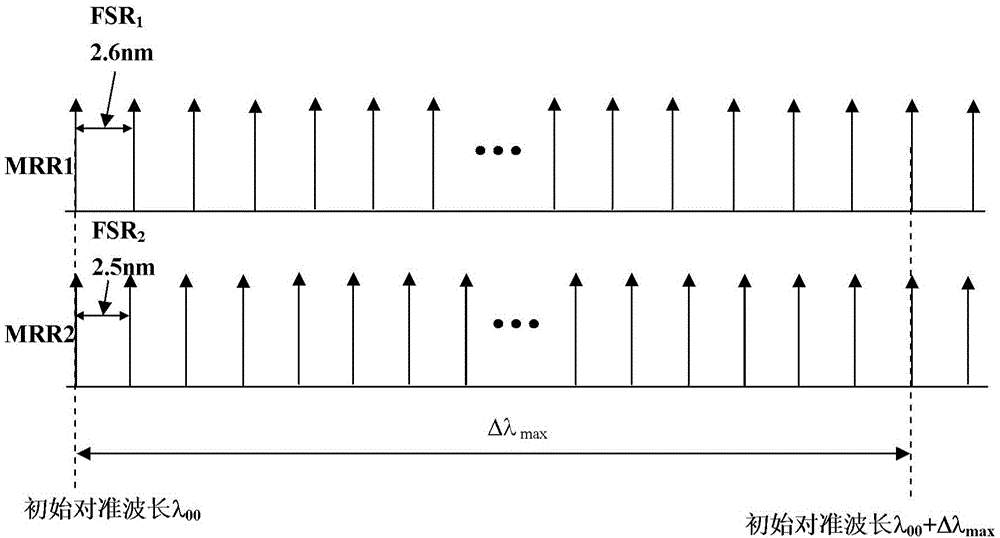

A filter and micro-ring technology, applied in the field of integrated optics, can solve the problems of large wavelength tuning, large heating current, frequency shift, etc., and achieve the effect of large-scale quasi-continuous filtering and precise thermo-optic tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0026] see figure 2 , figure 2 The structure and working principle diagram of a SOI planar optical waveguide thermo-optic tunable cascaded microring filter with a large wavelength tuning amount provided by the present invention includes:

[0027] An SOI single-mode input waveguide 10, preferably, the cross-sectional size of the waveguide is 450nm wide and 340nm high;

[0028] A single-mode connection waveguide 11, which is a horizontal U-shaped waveguide, one end of the U is used as the output waveguide of the first-stage SOI microring resonator 20, and the other end is used as the input waveguide of the second-stage SOI microring resonator 21 ;

[0029] A first-stage SOI microring resonator 20 with a radius of prefe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com