System and method for calibration optimizing experiment of hybrid power assembly based on working condition self-learning

A hybrid and self-learning technology, which is applied in the general control system, control/regulation system, adaptive control, etc., can solve the problems of difficult to meet the promotion and reference of hybrid vehicles, high cost, hardware resource limitations, etc., to achieve optimal And experimental verification, the effect of reducing the cost of optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

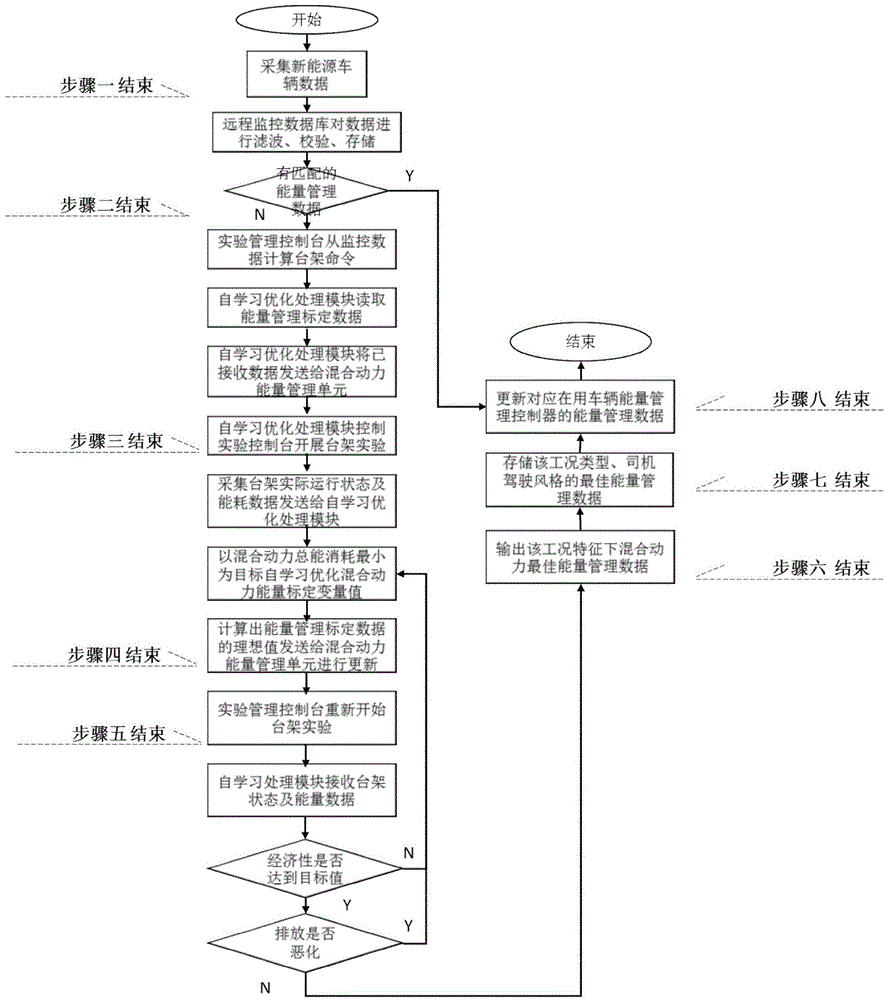

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

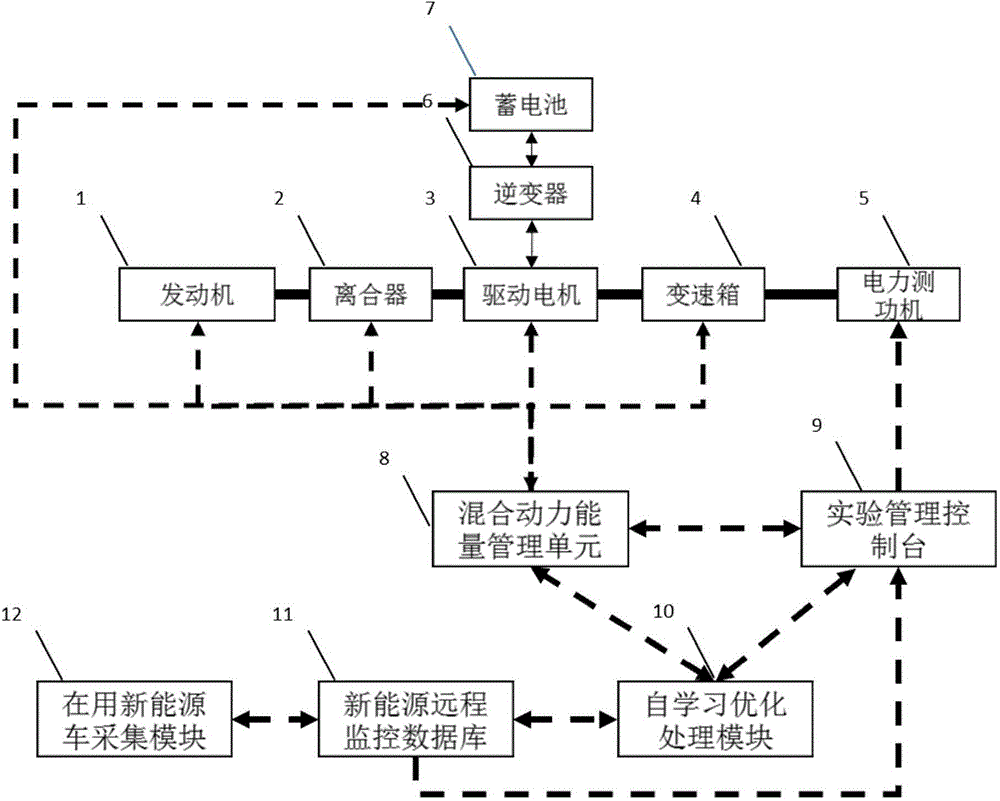

[0031] figure 1 Shown is the structure diagram of the hybrid powertrain optimization calibration experiment system based on working condition self-learning. A hybrid powertrain optimization calibration experimental system based on working condition self-learning of the present invention shown in the figure, the system includes:

[0032] A hybrid powertrain system, the hybrid powertrain system includes an engine 1, the engine is mechanically connected to a drive motor 3 via a clutch 2, as a power drive source for a hybrid vehicle, and the drive motor 3 is mechanically connected to a gearbox 4 connected, the drive motor 3 is sequentially connected with the inverter 6 and the storage battery 7 by cables to realize the bidirectional flow of electric energy;

[0033] A hybrid powertrain bench system, the hybrid powertrain bench system includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com