Composite sound absorption structure

A sound-absorbing and sound-absorbing board technology, which is applied in the direction of sound-producing equipment and instruments, can solve the problems of poor processing technology and the sound-absorbing characteristics of micro-perforated boards cannot be expanded to the maximum extent, so as to achieve controllable production costs, The sound absorption effect is remarkable and the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

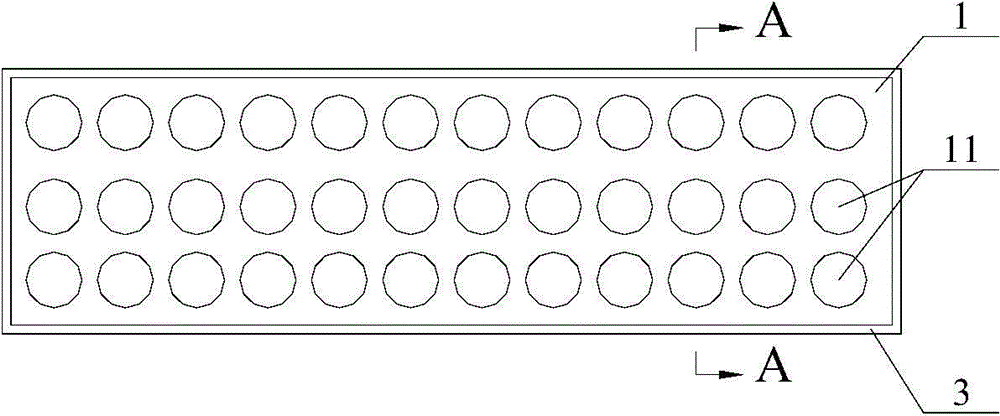

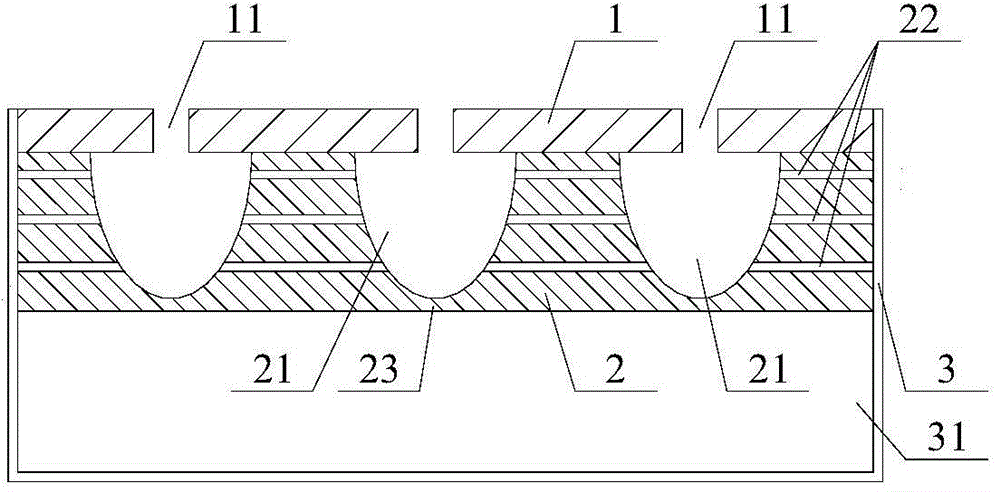

[0030] See figure 1 and figure 2 ,in, figure 1 It is a top view of the composite sound-absorbing structure described in this embodiment, figure 2 for figure 1 The A-A section diagram.

[0031] The composite sound-absorbing structure is composed of a sound-absorbing panel and a structural matrix 3 compositely connected with a resonant cavity 31 between them. The sound-absorbing panel is composed of a micro-perforated plate 1 and a plate base 2 that are attached together, and the cavity 31 is formed between the structural base 3 and the plate base 2 . Such as figure 1 As shown, the micro-perforated plate 1 is provided with a plurality of through sound-absorbing holes 11; here, the sound-absorbing holes 21 on the micro-perforated plate 1 are circular, in fact, the micro-perforated plate 1 can also be designed as a rectangle, Hexagonal, oval or irregular shapes. Such as figure 2 As shown, the panel base 2 is provided with a plurality of sound-absorbing cavities 21 , and...

Embodiment 2

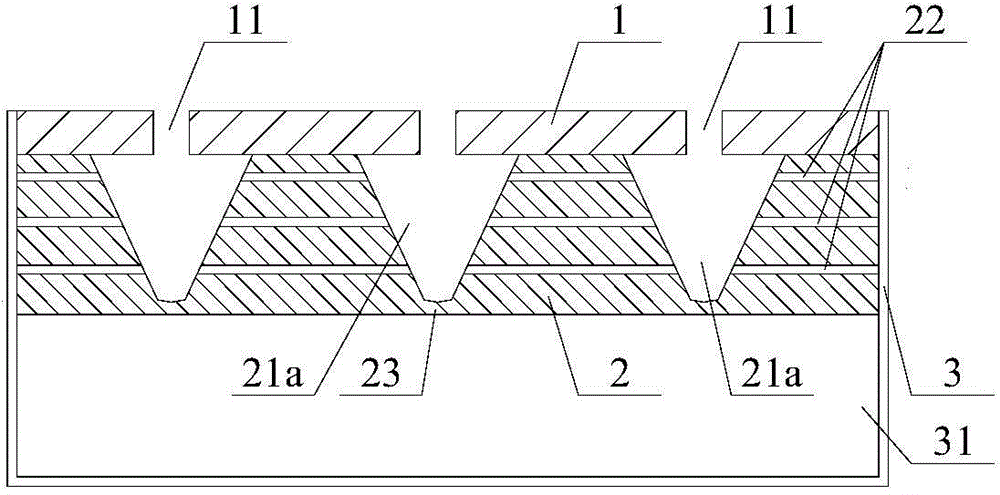

[0041] See image 3 , which shows a cross-sectional view of the composite sound-absorbing structure described in the second embodiment, and its cutting position is the same as figure 2 The cutting position is the same. In addition, it should be noted that the same functional components in the figure are shown with the same symbols, so as to clearly show the differences and connections between the two embodiments.

[0042] The difference between this solution and the first embodiment is that the cross-sectional profile of the sound-absorbing cavity in the first embodiment is a parabolic shape with an upward opening; while in this solution, the cross-sectional profile of the sound-absorbing cavity 21a is a conical shape with an upward opening. The composition and connection relationship are the same as those of the first embodiment, so this embodiment will not repeat them.

[0043] In summary, the present invention has the following advantages:

[0044] (1) The composite sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com