Preparation method of large-size graphene/graphite composite negative pole material

A technology of negative electrode material and large size, applied in the field of preparation of composite negative electrode material, can solve the problems of low initial coulombic efficiency, high discharge platform, low energy density and power density, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

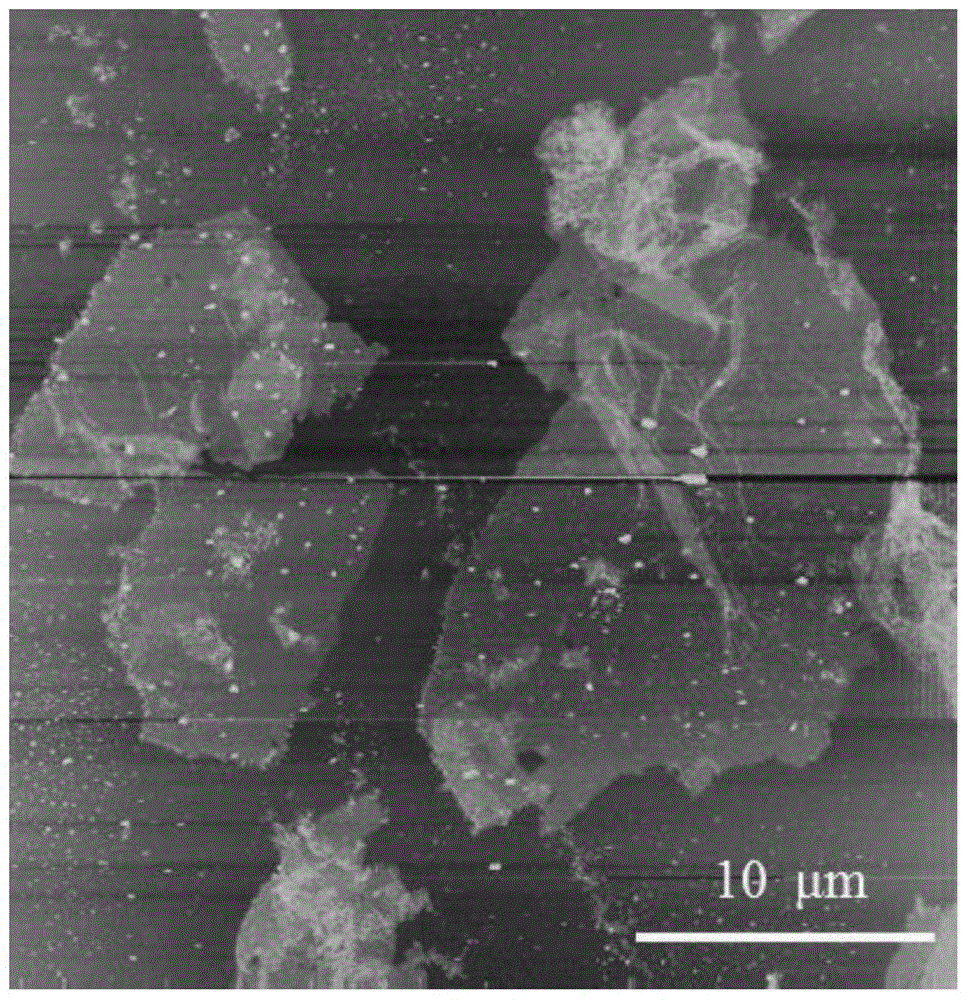

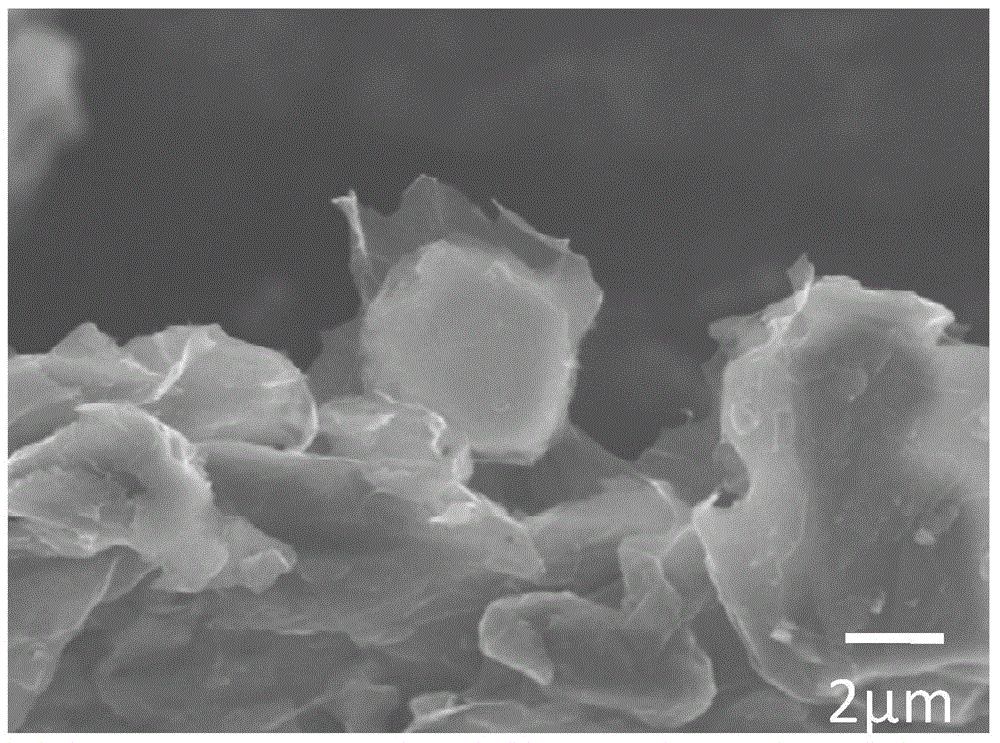

[0030] Specific embodiment one: this embodiment is a kind of preparation method of large-scale graphene / graphite composite negative electrode material and is finished according to the following steps:

[0031] 1. Preparation of large-size graphene oxide:

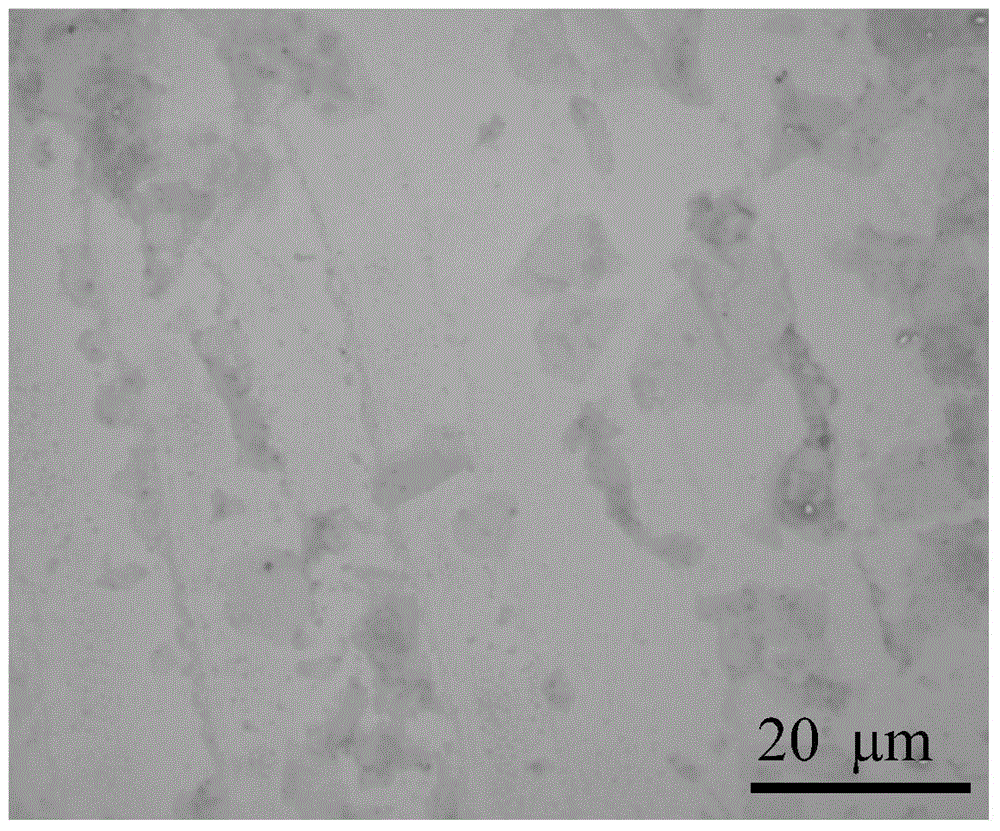

[0032] ①. Add flake graphite with a particle size of 300 μm to 500 μm into the mixed acid of sulfuric acid and nitric acid, then stir and react at a stirring speed of 300r / min to 500r / min for 24h to 48h, and then filter to obtain black powder ;Then use distilled water to wash the black powder 3 to 5 times, and then dry at a temperature of 60°C to 80°C for 12h to 24h to obtain the dried black powder; put the dried black powder into the power of 500W to 1000W 60s~180s in the microwave oven to get worm-like graphite;

[0033] The particle diameter described in step 1. is that the quality of the flake graphite of 300 μm~500 μm and the volume ratio of the mixed acid of sulfuric acid and nitric acid are 3g:(400mL~450mL);

[0034...

specific Embodiment approach 2

[0050] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the particle size of the large-sized graphene oxide obtained in step 1 ③ is 10 μm to 100 μm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0051] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the particle size of the graphite in step 2 ② is 10 μm-500 μm. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com