Integrated motor and actuator control method thereof

A control method and drive technology, which is applied in the direction of electric components, mechanical energy control, multiple motor speed adjustment, etc., can solve the problems of large volume and large diameter of motors, achieve the effects of reducing moment of inertia, reducing winding current, and solving safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

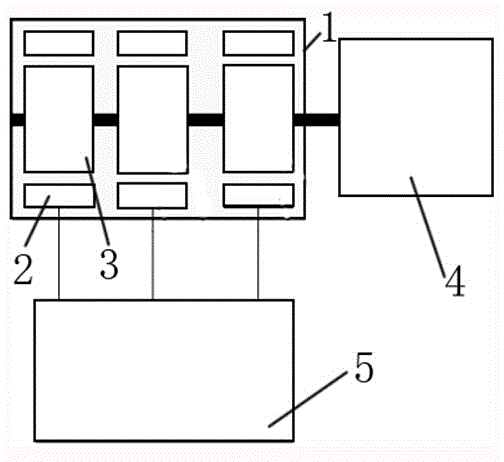

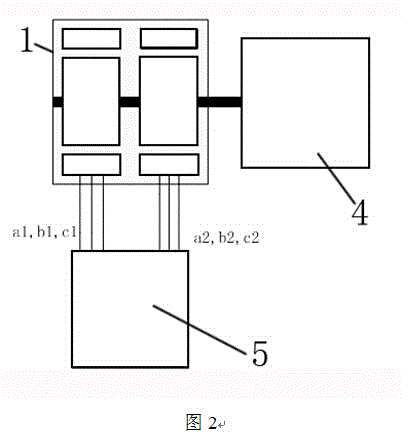

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

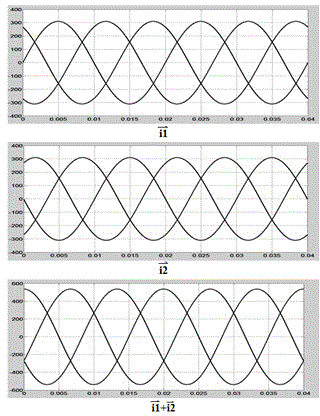

[0020] like figure 1 As shown, an integrated motor and its driver control method, including the control method of the integrated motor and the driver, the integrated motor includes a casing 1, stators and rotors of N motor units, and a driver 5, N The motor units are installed inside the same casing 1 and are coaxial, and N motor units provide power for the load 4 . The driver outputs N channels of 3-phase power supply, which are respectively electrically connected to drive N motor units. The N motor units, each motor unit includes a rotor 3 and a stator 2; the driver is a multi-channel 3-phase output driver, which can drive multiple independent motor units at the same time; the control method of the driver adopts three-phase drive control , each 3-phase output of the driver drives one of the motor units; the multi-channel 3-phase output driver can cut off the damage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com