Asymmetric rigid-flex circuit board and its preparation method

A rigid-flexible combination and asymmetric technology, which is applied in the fields of printed circuit manufacturing, printed circuit, printed circuit assembly of electric components, etc., can solve the problem of poor production yield of purely flexible areas, poor bonding force and easy delamination, Poor exposure of the flexible layer and other issues, to achieve the effect of enhanced product reliability, improved product reliability, and enhanced bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present application will be further elaborated below by way of examples.

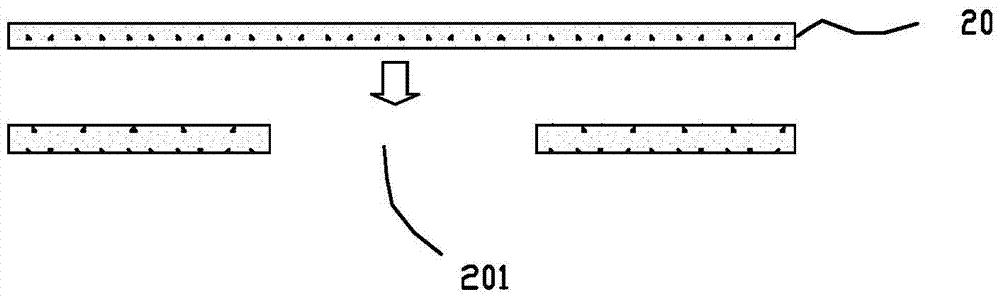

[0051] A method for preparing an asymmetric rigid-flex circuit board, the asymmetric rigid-flex circuit board comprising a rigid board, a dielectric layer and a flexible board stacked in sequence, the preparation method comprising the following steps:

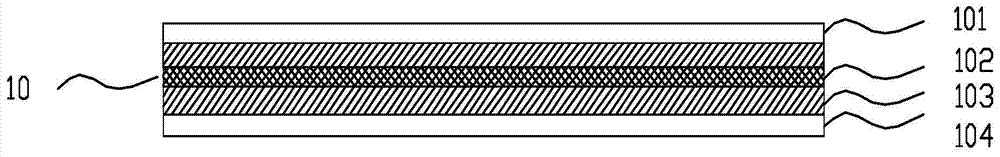

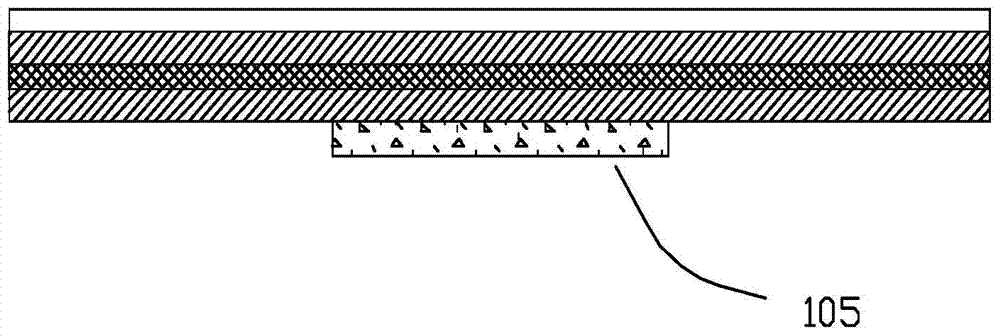

[0052] The production of the flexible board 10: the double-sided flexible board is etched, the copper layer 104 on one side is removed to expose the TPI layer 103 of the flexible board, and then the cover film 105 is pasted on the flexible area of the TPI layer (such as figure 2 shown).

[0053] The flexible board is made of a double-sided flexible board etched into a single side, so that the TPI layer is in contact with the dielectric layer, and the PI layer 102 is prevented from directly contacting the dielectric layer, so that the bonding force of the circuit board is better and the reliability is higher. (PI surface is smooth, has no bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com