Target device for inductive displacement measurement of a master piston

A technology of target equipment and displacement measurement, which is applied in the direction of electric/magnetic position measurement, mechanical equipment, measuring devices, etc., and can solve problems such as the inability to center the aluminum target body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

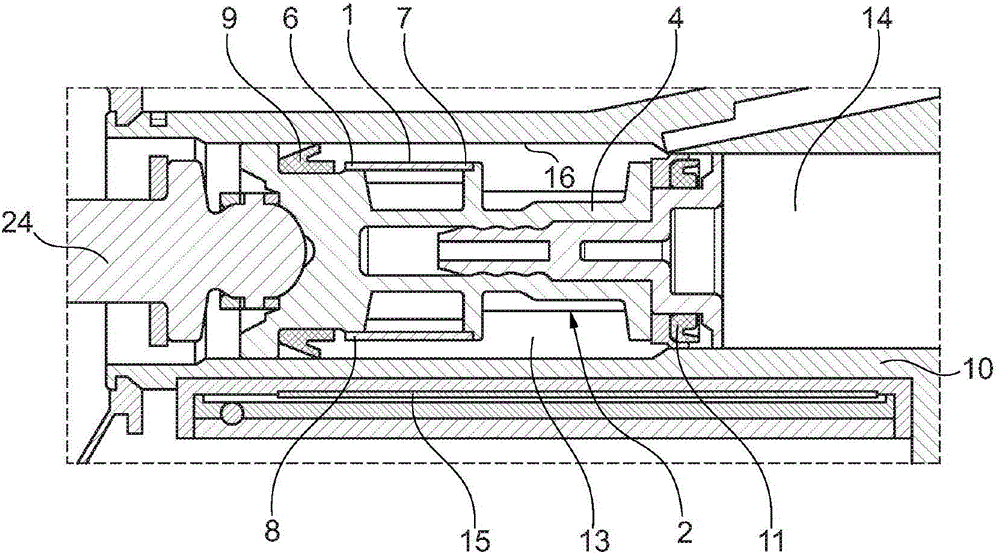

[0028] exist figure 1 shows a target device 1 which is applied to a piston body 4 . The piston body 4 is located in a master cylinder 10 with an inner wall 16 . The master cylinder 10 has a primary pressure chamber 13 and a secondary pressure chamber 14 . The piston body 4 is driven via an actuator 24 . For sealing, a first axial sealing ring 9 and a second axial sealing ring 11 are provided, the first axial sealing ring 9 sealing in the primary pressure chamber and the second axial sealing ring 11 in the secondary pressure chamber Sealing is performed in a state moving to the right according to the figure. The target device 1 is designed such that it can likewise be introduced into the secondary pressure chamber 14 . The target device 1 has a first end 6 and a second end 7 , wherein the first end 6 here forms a stop 8 for a first axial sealing ring 9 . The position of the piston body 4 or of the target device is registered via the induction coil 15 .

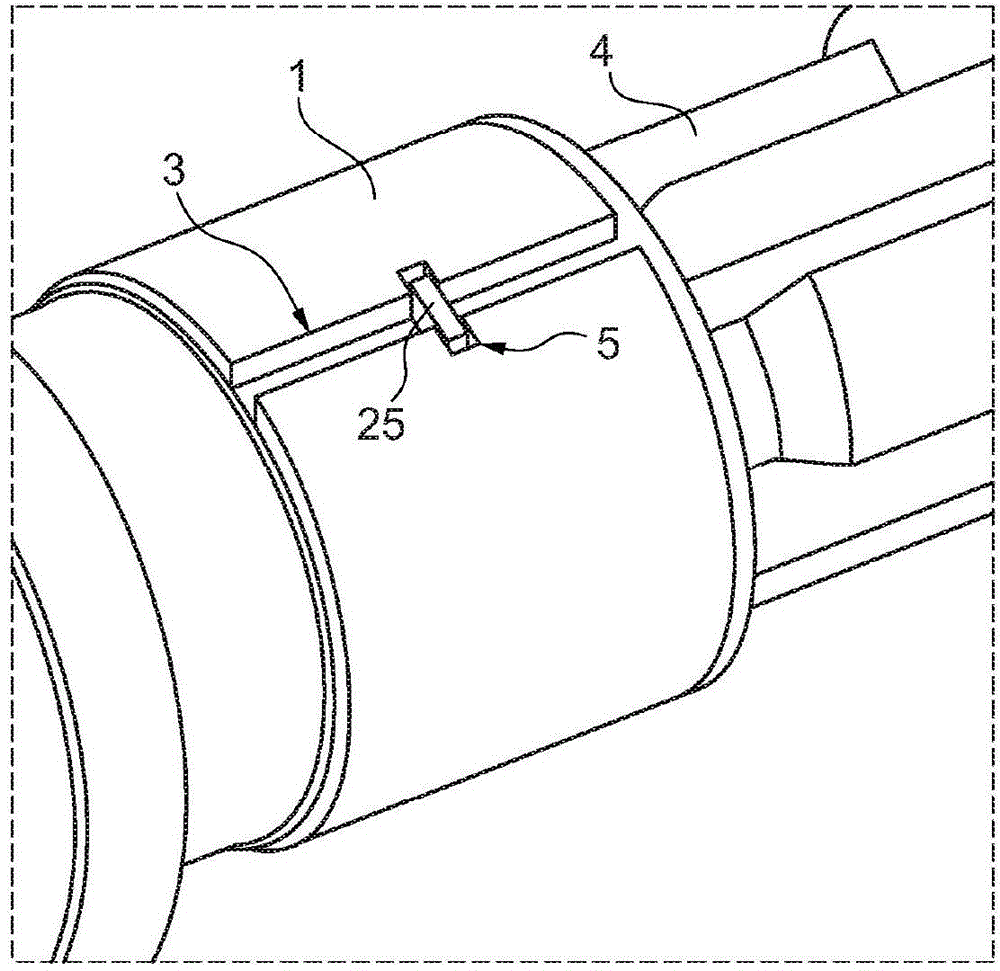

[0029] exist figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com