Yoke for universal joint and production method therefor

A technology of universal joints and manufacturing methods, which is applied in the direction of manufacturing tools, engine components, and assembly of parts into assemblies, etc., which can solve the problems of difficulty in strength design and achieve the effect of easy strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

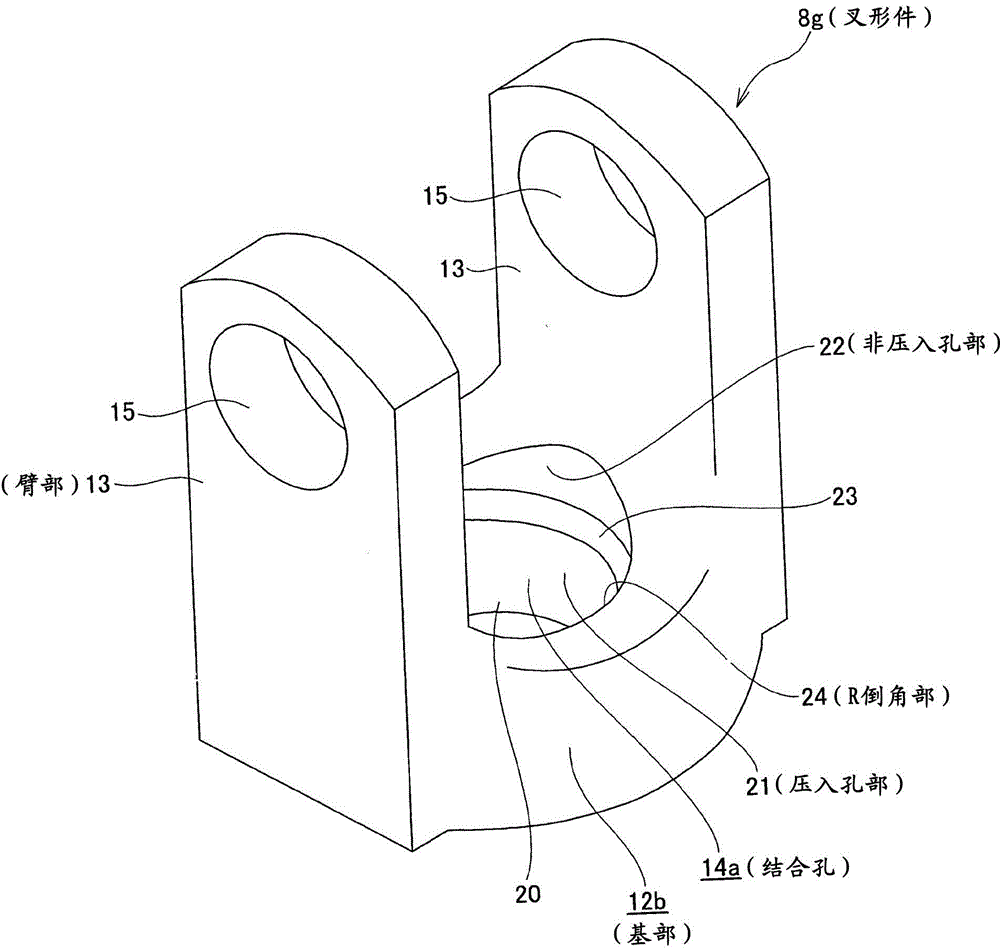

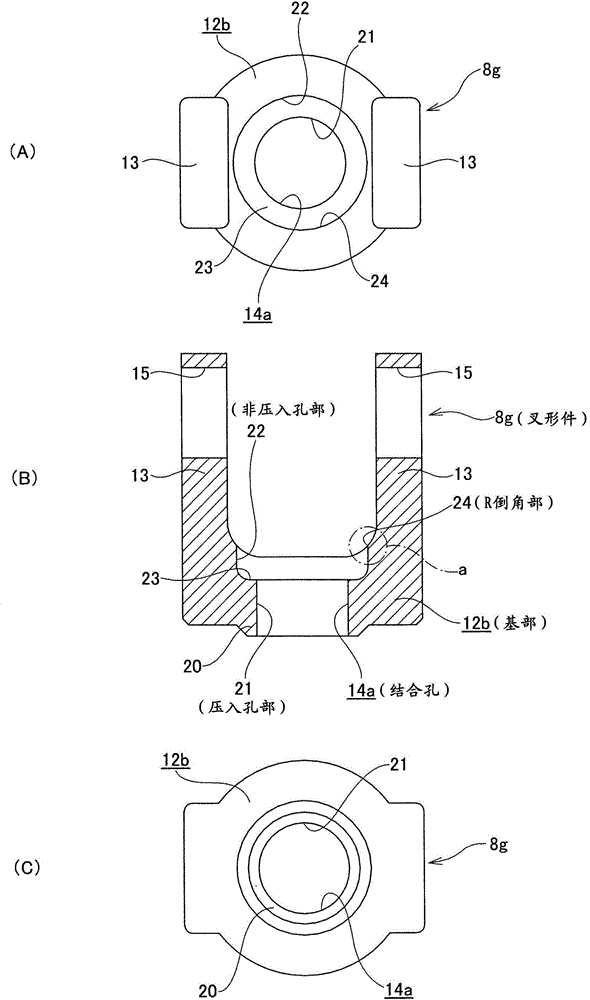

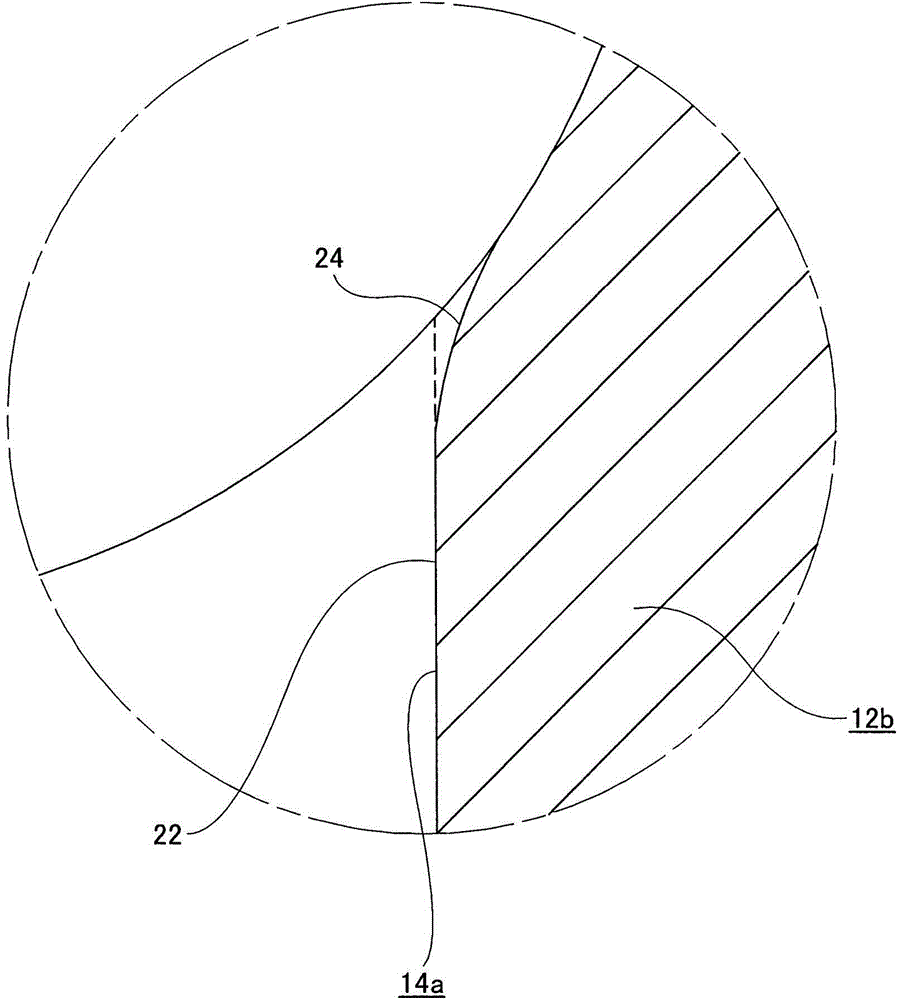

[0063] (First example of implementation)

[0064] Figure 1 ~ Figure 7 The first example of the embodiment of the present invention is shown. The features of this example are mainly the structure of the coupling hole 14a provided in the radial center portion of the base portion 12b, and the manufacturing method of the fork 8g provided with such coupling hole 14a. Including the aspect that the central portion of the other side surface of the base portion 12b in the axial direction is provided with the projecting ring portion 20 that can improve the welding strength, the structure and function of the other portions are the same as those described above. Figure 14 The second example of the conventional structure shown is the same, so that repeated descriptions are omitted or are briefly described. Hereinafter, the description will focus on the characteristic parts of this example. In the following description, in the axial direction of the fork 8g (and its intermediate material), o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com