Disinfectant and its preparation method and device

A technology for disinfecting liquid and mixing liquid, applied in the field of disinfecting liquid, can solve the problems of inability to use disinfection, unsafe, metal corrosion, etc., and achieve the effects of easy storage, safe use, and low corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

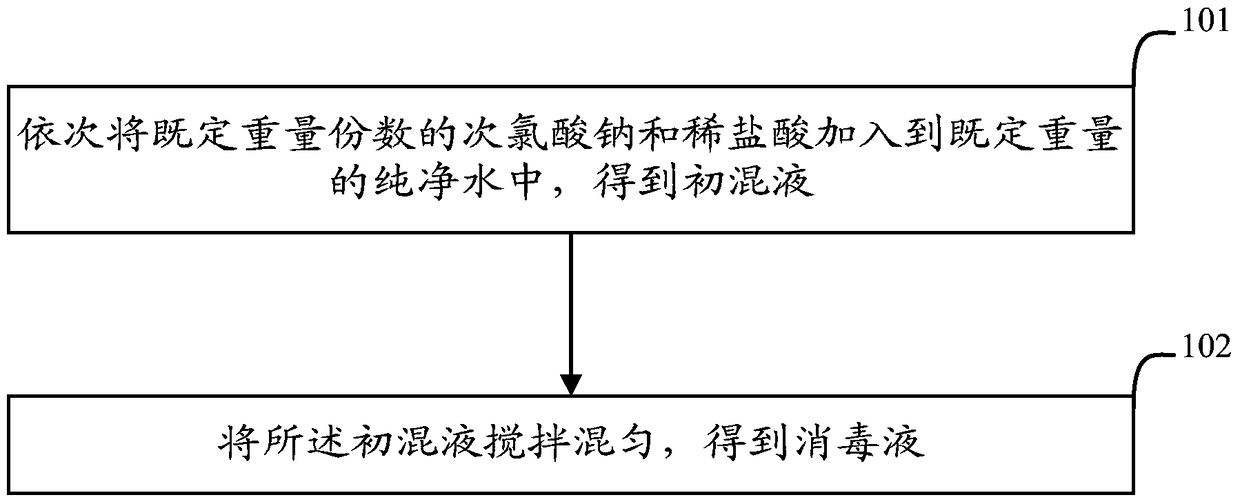

[0041] Please refer to figure 1 , the invention provides the preparation method of above-mentioned disinfectant, comprises the following steps:

[0042] Step 101: sequentially adding sodium hypochlorite and dilute hydrochloric acid in predetermined weight parts into pure water of predetermined weight to obtain an initial mixture;

[0043] In this step, in order to achieve the effect of mixing as soon as possible, preferably, the time used for adding the sodium hypochlorite and the dilute hydrochloric acid to the purified water is 0.1-5 seconds.

[0044] Step 102: Stir and mix the primary mixture to obtain a disinfectant solution.

[0045] In this step, the preferred stirring speed is 50 rpm and the time is 90 seconds.

[0046] Next, in combination with the above content, specific examples of the disinfectant solution of the present invention and its preparation method will be given.

Embodiment 1

[0048] The disinfectant solution provided by the embodiments of the present invention, in parts by weight, its raw material components include:

[0049] 99.3 parts of pure water, 0.4 part of sodium hypochlorite and 0.3 part of dilute hydrochloric acid, wherein the available chlorine content of sodium hypochlorite is 8%; the mass concentration of dilute hydrochloric acid is 10%. In addition, the specific weight of each part can be selected according to the capacity of specific manufacturing equipment, for example, it can be preferably 50 g.

[0050] Preparation

[0051] Sodium hypochlorite and dilute hydrochloric acid of given weight are added into purified water respectively within 3 seconds to obtain the initial mixed solution; the obtained initial mixed solution is stirred for 90 seconds at a rotating speed of 50 rpm; a disinfectant solution is obtained; standby (in use, specifically as a spray) use).

Embodiment 2

[0053] The disinfectant solution provided by the embodiments of the present invention, in parts by weight, its raw material components include:

[0054] 99.4 parts of pure water, 0.3 part of sodium hypochlorite and 0.3 part of dilute hydrochloric acid, wherein the available chlorine content of sodium hypochlorite is 7%; the mass concentration of dilute hydrochloric acid is 11%. In addition, the specific weight of each part can be selected according to the capacity of specific manufacturing equipment, for example, it can be preferably 50 g.

[0055] Preparation

[0056] Sodium hypochlorite and dilute hydrochloric acid of given weight are added into purified water respectively within 4 seconds to obtain the initial mixed solution; the obtained initial mixed solution is stirred for 90 seconds at a rotating speed of 50 rpm; a disinfectant solution is obtained; standby (in use, specifically as a spray) use).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com