Once-formed soft bag connector and infusion soft bag with same

A molding and interface technology, applied in the field of infusion soft bags, can solve the problems of complex production process, poor sealing, secondary pollution, etc., and achieve the effect of reducing pollution, preventing denaturation and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

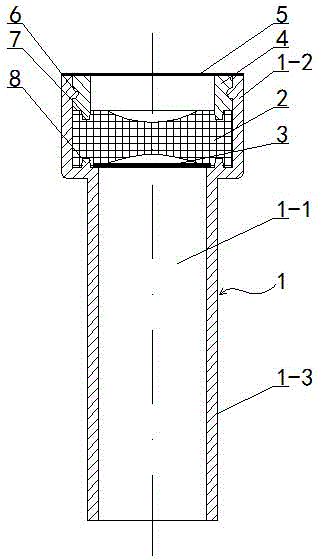

[0040] as attached figure 1 As shown, the one-time molded soft bag interface is mainly composed of an interface body 1, a rubber plug 2, a sealing diaphragm 3, a sealing pressure ring 4 and a sealing film 5.

[0041] The interface body 1 is a one-time molding structure, with a drug infusion channel 1-1 inside, a sealing port 1-2 at one end, and a welding part 1-3 at the other end.

[0042] The sealing port 1-2 is used to cooperate with the rubber plug 2, the sealing diaphragm 3, the sealing pressure ring 4 and the sealing film 5 to form the sealing structure of the interface. The sealing port 1-2 is coaxially arranged on the upper end of the interface body 1, and its inner diameter is slightly larger than the diameter of the drug delivery channel 1-1, and is located at the junction of the sealing port 1-2 and the drug delivery channel 1-1. Form a shoulder. The sealing diaphragm 3 is fixedly arranged on said shoulder. The sealing film 5 is fixedly arranged at the opening end...

Embodiment 2

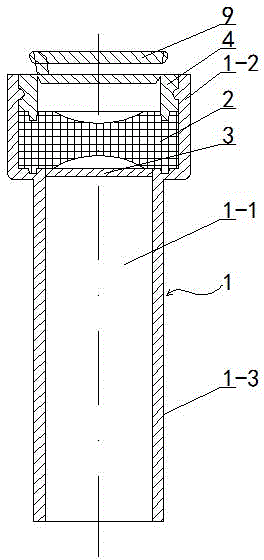

[0048] as attached figure 2 As shown, the once-formed soft bag interface is mainly composed of an interface body 1, a rubber plug 2, a sealing diaphragm 3, a sealing pressure ring 4 and a sealing pull ring 9.

[0049] The structure and connection relationship of the interface body 1, the rubber plug 2, and the sealing pressure ring 4 are basically the same as those in the first embodiment. The main differences are:

[0050] 1. The sealing diaphragm 3 is integrally formed with the interface body 1, and its position is located at the shoulder;

[0051] 2. A sealing pull ring 9 is fixed on the top of the sealing pressure ring 4, and the dustproof effect is achieved through the sheet-shaped sealing structure of the sealing pull ring 9.

Embodiment 3

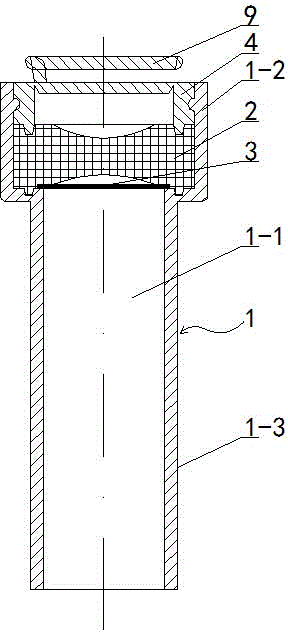

[0053] as attached image 3 As shown, the once-formed soft bag interface is mainly composed of an interface body 1, a rubber plug 2, a sealing diaphragm 3, a sealing pressure ring 4 and a sealing pull ring 9.

[0054] The structure and connection relationship of the interface body 1, the rubber plug 2, the sealing diaphragm 3, and the sealing pressure ring 4 are basically the same as those in the first embodiment. The main difference is that a sealing ring 9 is fixed on the top of the sealing pressure ring 4 , and the dust-proof effect is achieved through the sheet-shaped sealing structure of the sealing ring 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com