A multi-cytokines sequential slow-release microsphere-hydrogel composite system and its preparation method

A composite system and slow-release microsphere technology, which is applied in the field of multi-cytokine sequential slow-release microsphere-hydrogel composite system and its preparation field, can solve the problem that seed cells and cytokines cannot aggregate, proliferate, and affect the repair of defective cartilage. Issues such as speed and extent, and reduced efficacy of stem cell homing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

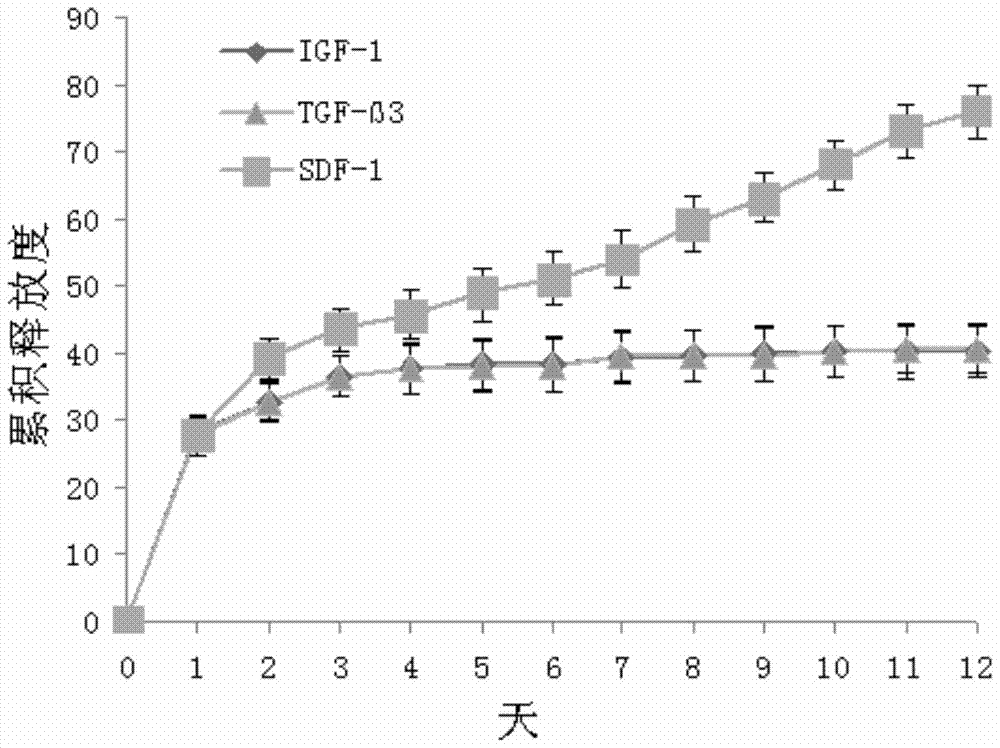

[0047] Example 1. Preparation of IGF-1-loaded PLGA Microspheres

[0048] The W / O / W emulsification-solvent evaporation method was used to prepare IGF-1-loaded PLGA microspheres. The specific process was as follows: 1 mg of rhIGF-1 freeze-dried powder was dissolved in 100 μl of deionized water to prepare an aqueous solution with a concentration of 10 mg / ml as The inner aqueous phase (W1 phase). Take 500mg of PLGA and 140mg of Span-80 dissolved in 10ml of dichloromethane, as the oil phase (O phase). Add the W1 phase to the O phase, and ultrasonically emulsify for 1 min with an ultrasonic cell pulverizer under ice bath to form the primary emulsion W1 / O. Slowly and uniformly add W1 / O primary emulsion into 100ml of 2% (w / v) PVA aqueous solution containing 150mg tween-80 (outer water phase W2) under continuous stirring, and stir magnetically at a constant speed of 3000rpm under ice bath for 10min to form W1 / O / W2 double layer complex emulsion. Then magnetically stir at a constant ...

Embodiment 2

[0049] Example 2. Preparation of TGF-ß3-loaded PLGA microspheres

[0050] The W / O / W emulsification-solvent evaporation method was used to prepare TGF-ß3-loaded PLGA microspheres. The specific process was as follows: 1 mg of rhTGF-ß3 lyophilized powder was dissolved in 100 μl of deionized water to prepare an aqueous solution with a concentration of 10 mg / ml as The inner aqueous phase (W1 phase). Take 500mg of PLGA and 140mg of Span-80 dissolved in 10ml of dichloromethane, as the oil phase (O phase). Add the W1 phase to the O phase, and ultrasonically emulsify for 1 min with an ultrasonic cell pulverizer under ice bath to form the primary emulsion W1 / O. Slowly and uniformly add W1 / O primary emulsion into 100ml of 2% (w / v) PVA aqueous solution containing 150mg tween-80 (outer water phase W2) under continuous stirring, and stir magnetically at a constant speed of 3000rpm under ice bath for 10min to form W1 / O / W2 double layer complex emulsion. Then magnetically stir at a constan...

Embodiment 3

[0051] Example 3. Preparation of PLGA-PEG-PLGA hydrogel

[0052] The PLGA-PEG-PLGA block copolymer hydrogel was prepared by the ring-opening polymerization method. The specific method is: weigh a certain amount of DLLA, GA and PEG1500 according to the ratio of DLLA:GA:PEG=6:1:3 and put them in the oven After drying in medium for 2 hours, mix it and add it to the vacuum polymerization reaction bottle, place it at room temperature for 2 hours to cool, then add the catalyst stannous isooctanoate (0.02%, W / W), repeat nitrogen and vacuum, remove trace moisture and oxygen, Vacuum seal the tube, heat to 150°C and react for 10 hours to obtain PLGA-PEG copolymer. Afterwards, the polymer was dissolved in dichloromethane, and ethanol was precipitated out to obtain a purified polymer, which was dried in vacuo to constant weight to obtain a viscous transparent product, which was stored at -20°C for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com