Wear protection assembly for an agitator mill

An agitated ball milling, anti-wear technology, applied in grain processing and other directions, can solve the problem of insufficient wear protection, achieve good dimensional deviation, prevent contact, and reduce the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

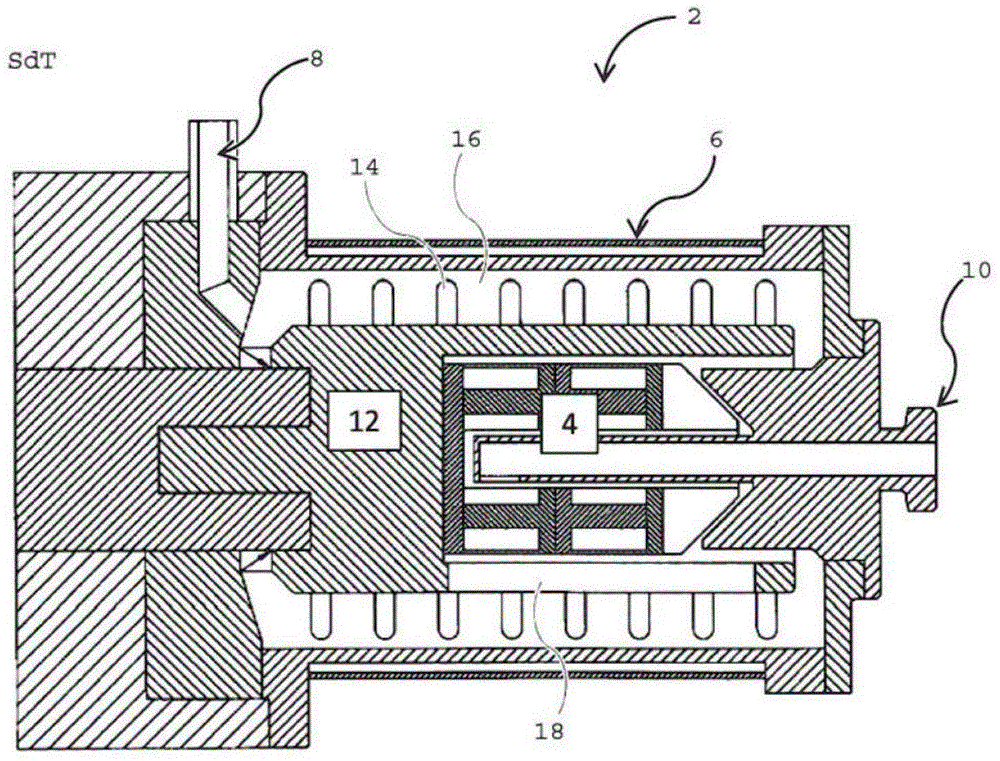

[0061] figure 1 The configuration of a known agitator ball mill 2 with a separating device 4 is shown schematically. The shown agitator ball mill 2 comprises a milling vessel 6 provided with a milling substance inlet 8 and a milling substance outlet 10 . A stirrer in the form of a stirrer shaft 12 is arranged centrally in the grinding container 6 . The stirring shaft 12 is provided with pin-shaped stirring bodies 14 which protrude into the grinding space 16 . The separating device 4 is provided inside the stirring shaft 12 . During operation of the grinder 2 , the medium to be ground is fed through the grinding material inlet 8 and conveyed in the direction of the grinding material outlet 10 . A grinding aid (not shown) is located in the grinding space 16 between the stirring shaft 12 and the grinding container 6 . The grinding substance-grinding auxiliary body-mixture is separated in the end region of the grinder 2 by means of the separating device 4, so that only the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com