Portable differential reaming device and using method thereof

A portable and reaming technology, which is applied in reaming devices, reaming devices, metal processing equipment, etc., can solve problems such as reaming space limitations, and achieve assembly accuracy, improve dimensional accuracy and surface processing quality, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

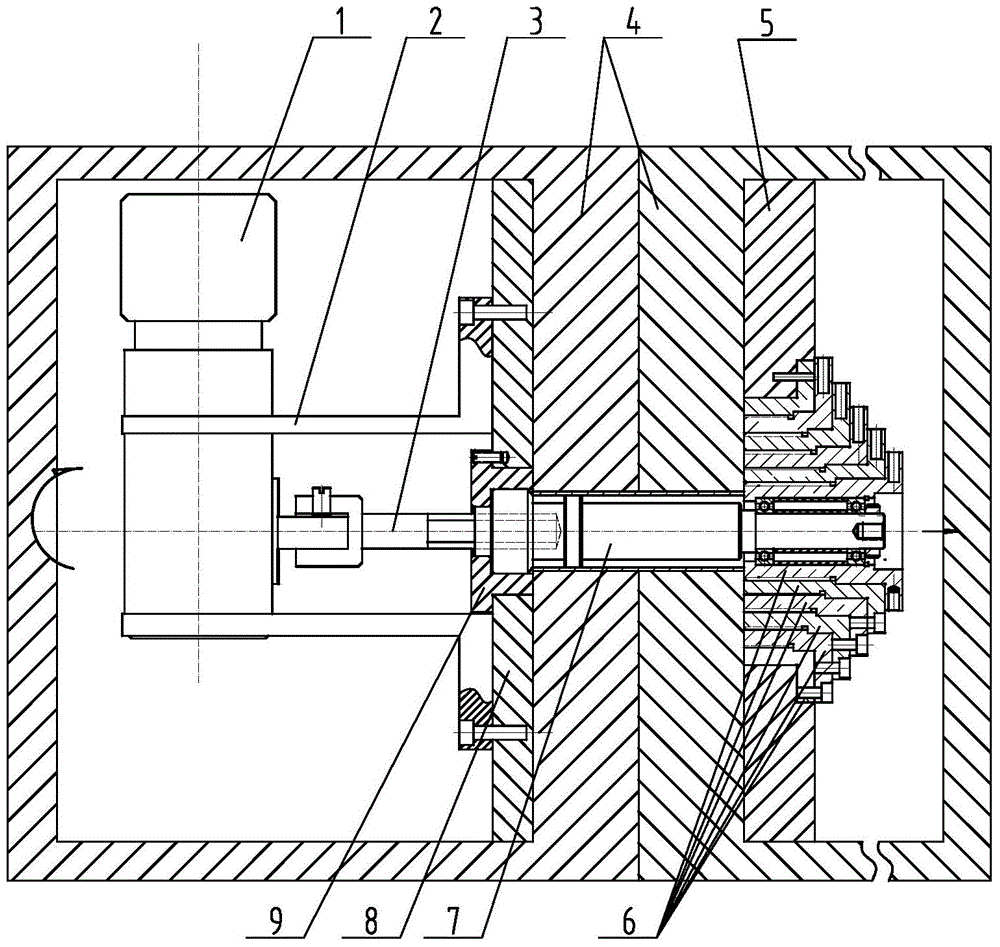

[0017] Such as figure 1 As shown, a portable differential reaming device includes a motor 1, a first positioning plate 8, a second positioning plate 5, a differential feed mechanism 6, a reamer 7, a coupling 3 and a guide sleeve 9. The motor 1 uses a micro motor with a planetary reducer, which is relatively small in size and meets the installation requirements in a limited space. The motor 1 is fixed to the first positioning plate 8 through the motor guide bracket 2 to fix the position of the motor 1. The output shaft of the motor 1 is connected to the reamer 7 through the coupling 3 to realize torque transmission. The guide sleeve 9 is sleeved at one end of the reamer 7 connected with the coupling 3, which can play a certain guiding role when inserting the knife to avoid the position of the machining aperture due to the end deflection during machining deviation. The differential feed mechanism 6 is composed of a set of sleeves with threads both inside and outside. The diffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com