Spherical box bottom circumferential seam welding method for 5M-grade thin wall storage box

A circular seam welding and super-thin-walled technology, which is applied in the field of circular seam welding at the bottom of spherical tanks with 5M thin-walled storage tanks, can solve the problems of scrapping the bottom of the tank, the inability to guarantee the stability of welding quality, and the inability to apply larger diameter storage tanks, etc. Achieve the effect of avoiding wrong seams and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

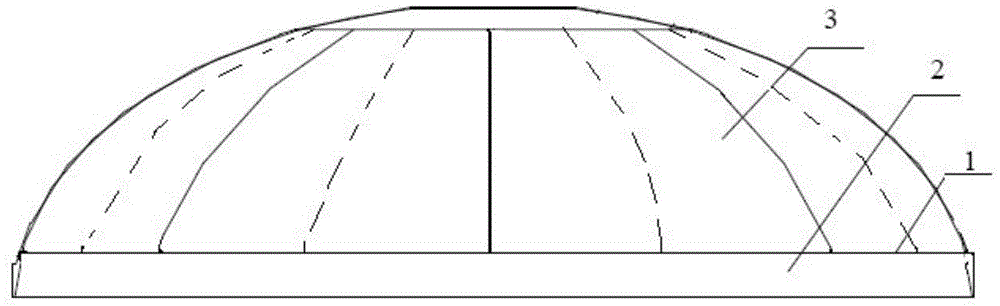

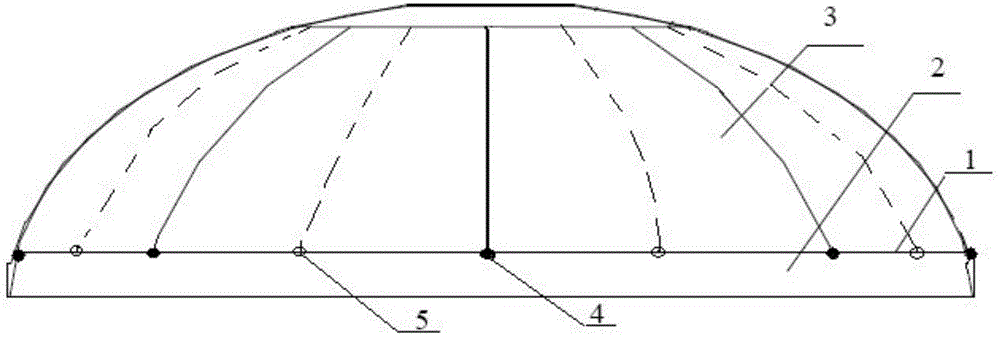

[0015] figure 1 Shown is a schematic structural view of the spherical tank bottom of the tank provided by the embodiment of the present invention. Such as figure 1 As shown, the upper end of the box bottom is composed of a plurality of melon petals of the same size that are tailor-welded to form a circular ring 3, the lower end of the box bottom is composed of a transition ring 2, and a circular seam 1 is formed between the circular ring 3 and the transition ring 2. By welding the ring seam 1, an integral box bottom is formed.

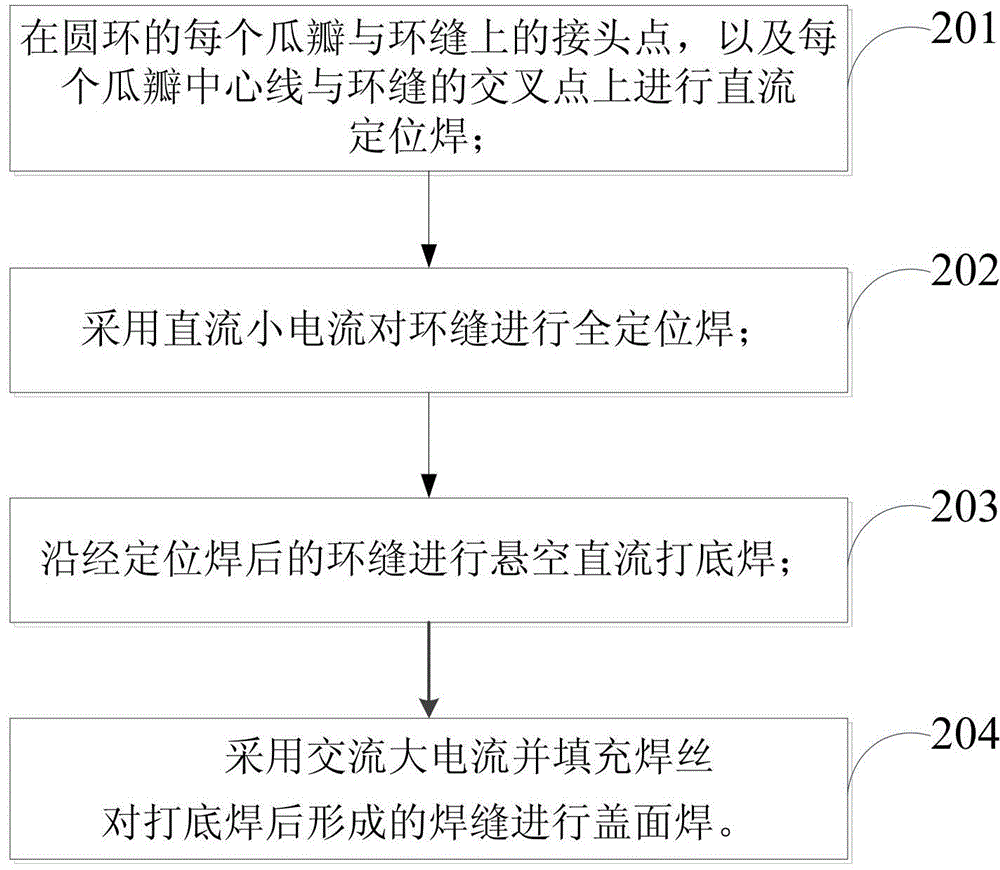

[0016] figure 2 Shown is a schematic flow chart of the welding method for the girth seam of the spherical bottom of the tank provided by an embodiment of the present invention. Such as figure 2 As shown, the metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com