TIG welding head with multi-axis servo movement mechanism and welding method

A technology of welding head and servo motion, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of inability to realize remote monitoring and control, inability to meet the welding of small-pitch pipe rows, technical level and performance gap, etc. Achieve the effect of realizing single-pass multi-layer welding, reducing the probability of occurrence of macro-defects in welds, and reducing welding line energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

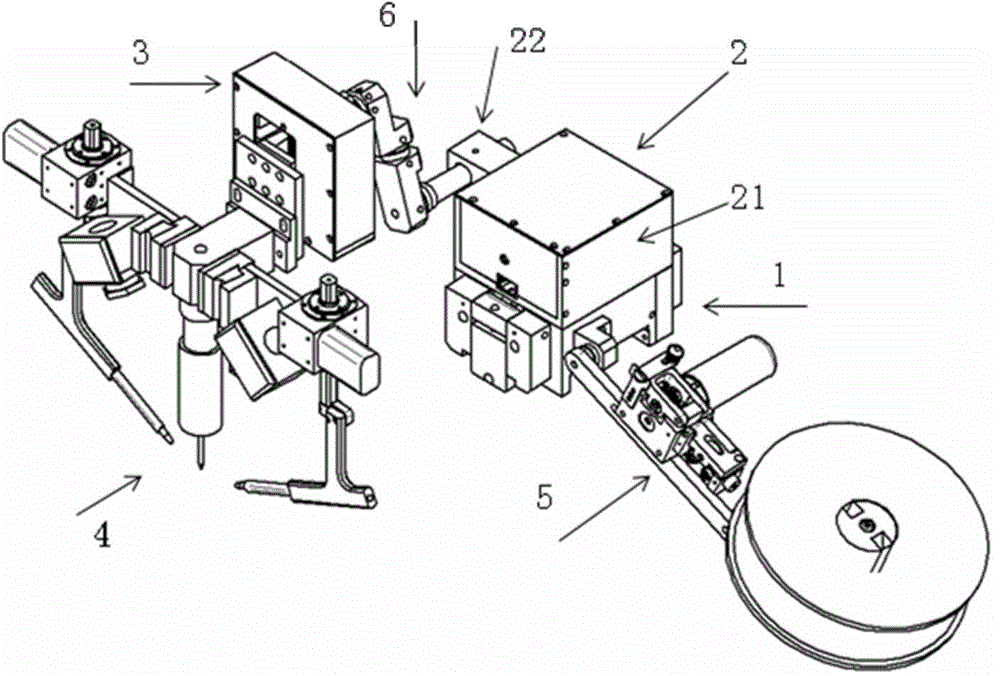

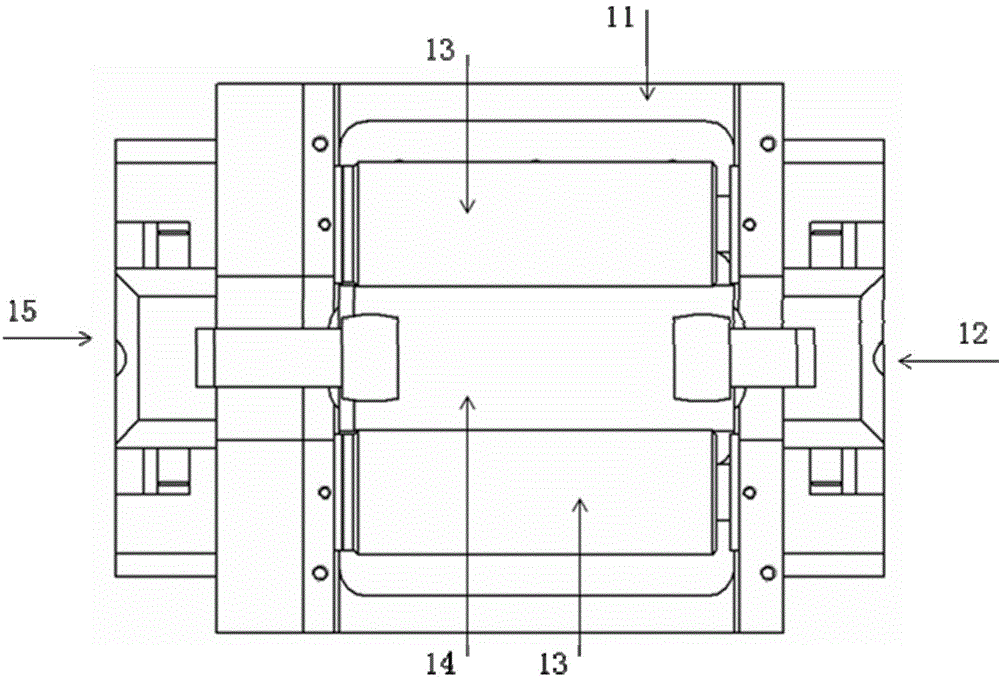

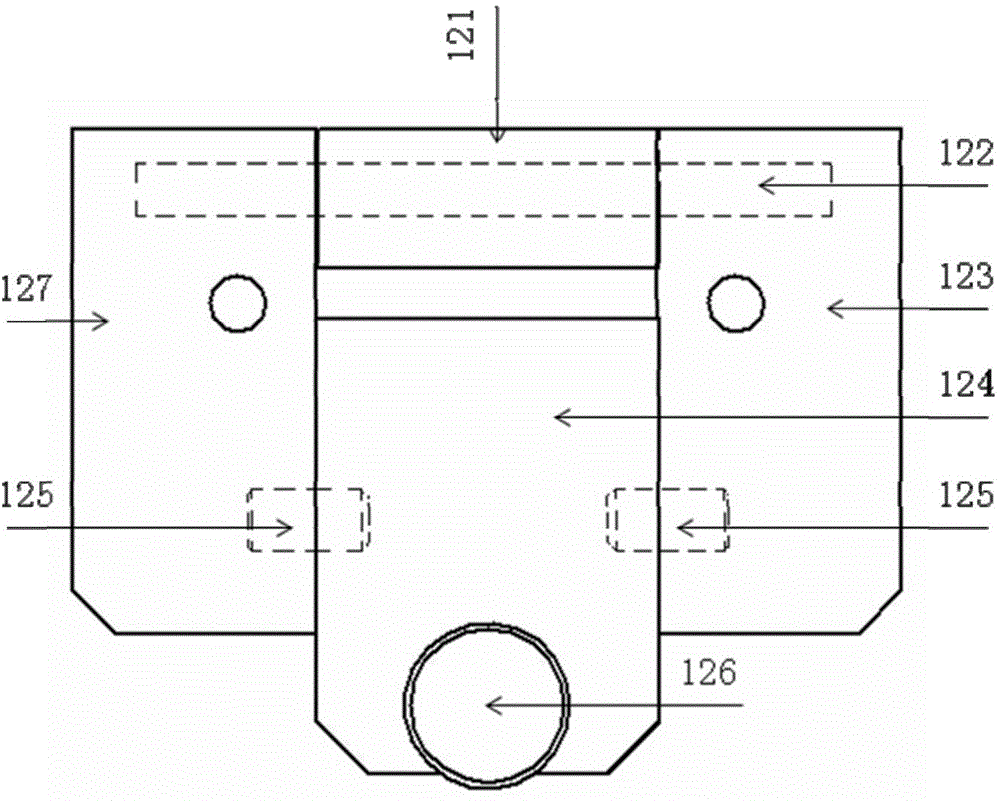

[0049] like figure 1 As shown, the present invention provides a TIG welding head with a multi-axis servo motion mechanism, especially a TIG welding head with an 8-axis servo motion mechanism, including: a traveling mechanism 1, a swing mechanism 2, an up and down Adjusting mechanism 3, front-end welding mechanism 4, wire feeding mechanism 5 and welding torch angle adjusting arm 6;

[0050] The traveling mechanism 1 matches the traveling track installed on the surface of the workpiece to be welded, so that the TIG welding head moves along the traveling track, and the traveling track corresponds to the welding seam. The wire feeding mechanism 5 is installed on the side of the traveling mechanism 1, and For the supply of welding wire when the TIG welding head is welding, the swing mechanism 2 is fixed above the traveling mechanism 1, and the swing mechanism 2 is connected to one side of the up and down adjustment mechanism 3 through the welding torch angle adjustment arm 6, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com