Dual-purpose tool for screwing studs through interference threads or unthreaded hole and use method thereof

A threaded hole and screw pile technology is applied in the field of assembly tooling for interference thread and smooth hole upper screw pile. It can solve the problems of production preparation and arrangement influence, thread hole damage, and long production preparation cycle, so as to achieve flexible use and reduce tooling. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

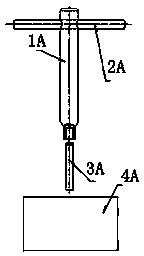

[0062] Example 1: A screw pile with an interference thread with a specification of AG6×1

[0063] 1) Check the screw pile hole and the screw pile, they should be clean and free of foreign matter, and check the group of the screw pile hole with a thread measuring tool;

[0064] 2) Select the corresponding group of screw piles, and screw the ordinary threaded end of the screw pile into the threaded hole of the tooling;

[0065] 3) Lubricate with a good lubricant as needed during assembly. When lubricating blind holes, it is necessary to prevent excessive lubricant from producing hydraulic resistance in blind holes, hindering assembly or causing metal extrusion and cracks in parts. Apply a thin layer of lubricating oil on the interference thread end and screw it into the workpiece for about 2 buckles. After a good hand feel, screw the stud into the shell with tooling to ensure that the height of the stud protruding out of the shell should meet the requirements of the drawing.

Embodiment 2

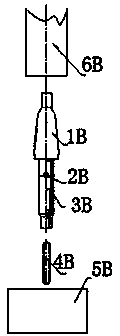

[0066] Example 2: Screw piles with a specification of M5 on the light hole

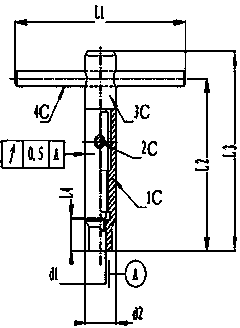

[0067] 1) Check that the runout of the dual-purpose tooling should be within 0.4, the surface roughness of the clamping part should not be higher than Ra3.2, and remove the handle of the dual-purpose tooling;

[0068] 2) Use the Z5625 4C row drilling machine, put the standard drill chuck into the spindle hole of the drilling machine, put the dual-purpose tooling into the drill chuck and lock the drill chuck.

[0069] 3) Due to the large torque when screwing on the pile, flat-nose pliers should be used to clamp and fix the workpiece. The material of the workpiece is cast aluminum such as ZL101, and the workpiece should be avoided from being pinched. There should be no burrs and foreign objects in the workpiece hole, and the wall thickness at the threaded hole should not be less than 2.5.

[0070] 4) Screw the screw pile into the tooling until the bottom of the threaded hole. The material of the screw p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com