Automatic production equipment for manufacturing tubular aluminum containers and application method of equipment

A technology of automatic production and container manufacturing, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of reducing production efficiency, reducing product qualification rate, and increasing production costs, so as to shorten the production cycle, improve quality effects, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

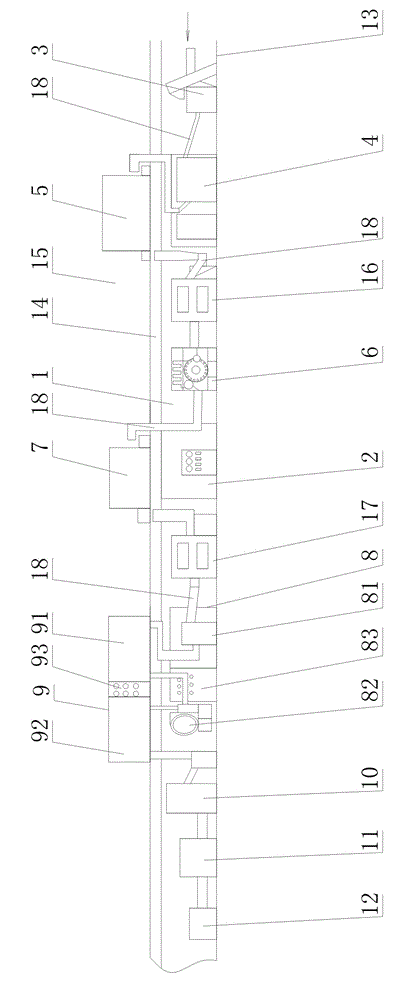

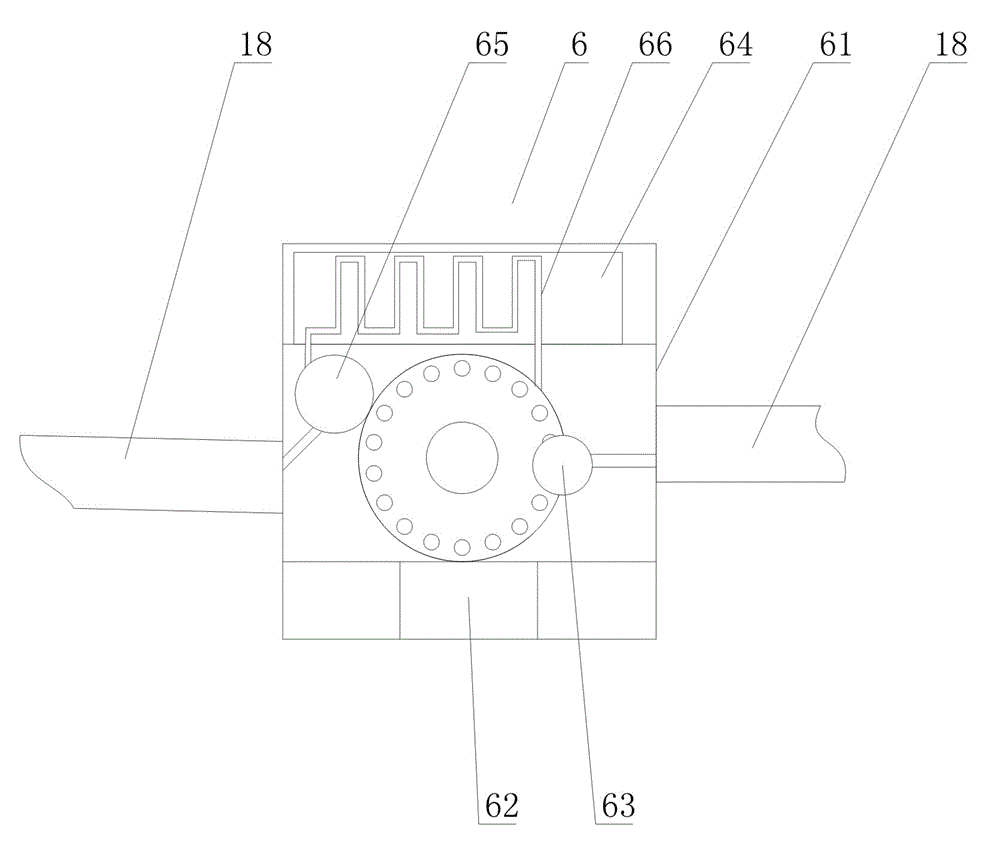

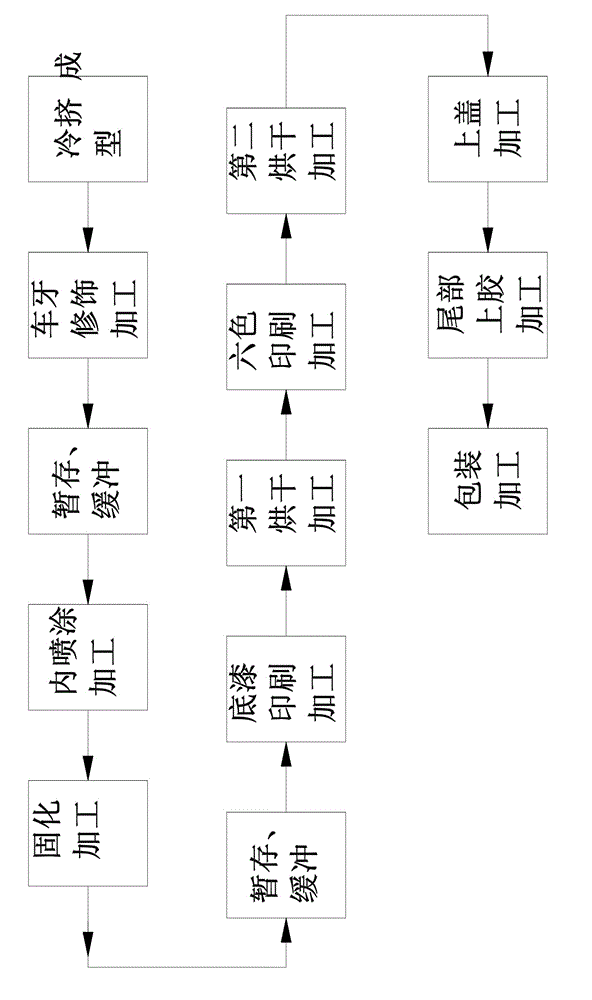

[0029] Below in conjunction with accompanying drawing, the present invention will be further described, Figure 1 to Figure 3Showing an embodiment of the present invention, the automatic production equipment includes an operating room 1, a monitoring drive device 2, a cold extrusion stamping device 3, a tooth modification device 4, an annealing device 5, an internal spraying device 6, a curing device 7, and a printing device 8. Drying device 9, automatic capping device 10, tail coating device 11 and packaging device 12. The cold extrusion stamping device 3, the tooth modification device 4, the annealing device 5, the internal spraying device 6, the curing device 7, the printing device 8, the drying device 9, the automatic capping device 10, the tail coating glue device 11 and the packaging device 12 are sequentially connected by workpiece conveying parts 18 respectively. The monitoring driving device 2 and the cold extrusion stamping device 3, the tooth modification device 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com