Elastic fixture for bellows sleeve

A bellows sleeve and fixture technology, used in clamping, clamping devices, manufacturing tools, etc., can solve the problems of sensitive cutting heat, difficult to guarantee manufacturing accuracy, and damage to fixtures, so as to achieve convenient manufacturing and installation, and little influence of cutting heat , The effect of uniform clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

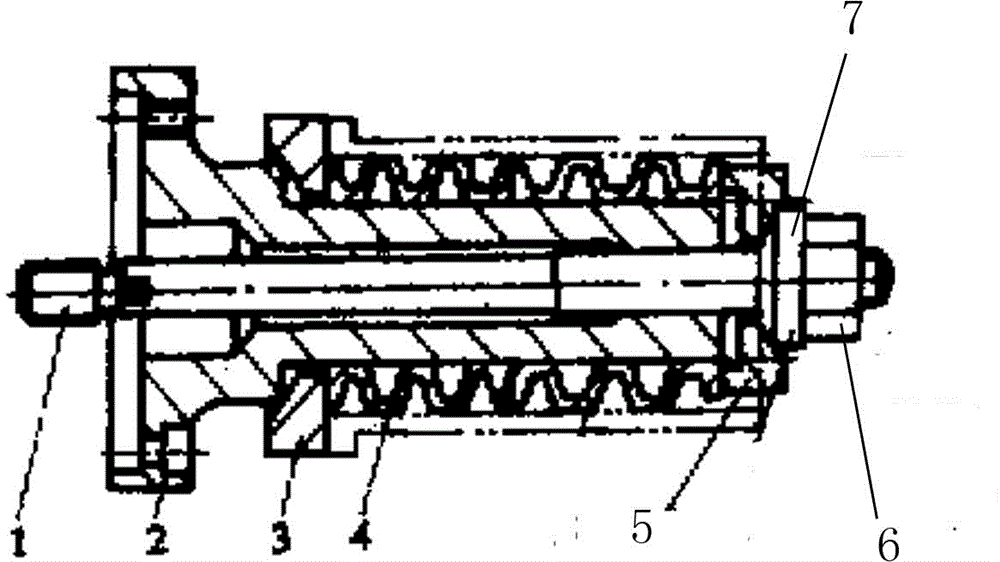

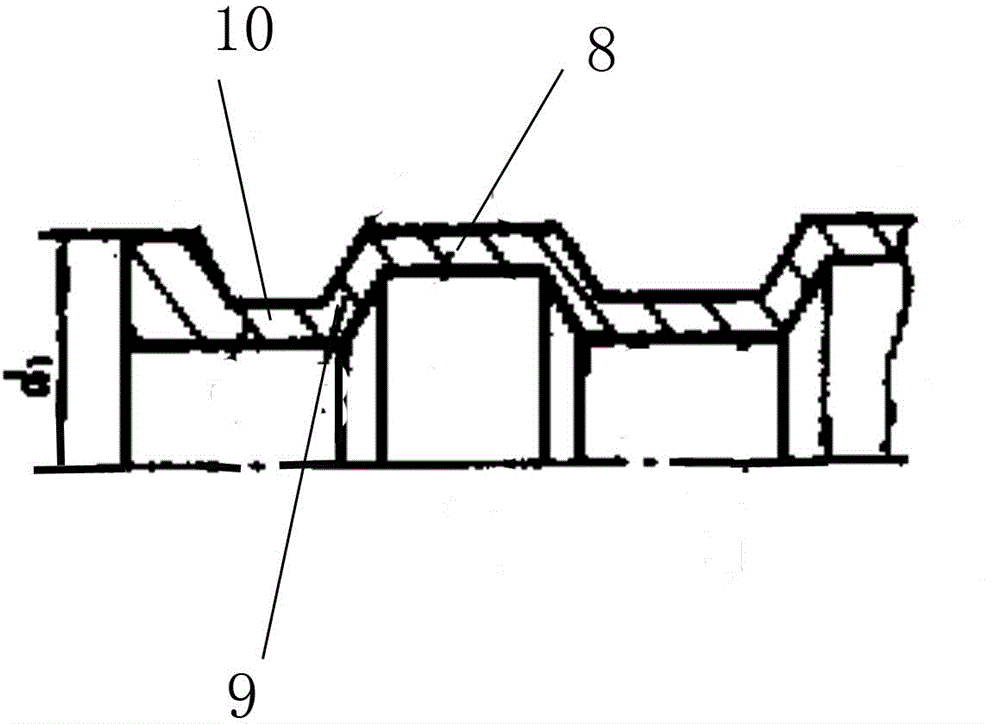

[0013] The accordion sleeve elastic clamp of the present invention includes a clamp body 2 fixedly connected to the workbench, the clamp body 2 is stepped cylindrical, and an axial central step through hole is opened on the clamp body 2, and a clamp body 2 is installed in the clamp body 2 The pull rod 1 protrudes from the through hole of the clamp body 2, and a pressure plate 7 is connected to one end through a lock nut 6, and a bellows sleeve 4 is sleeved on the step at the end of the clamp body 2. A spherical pad is respectively connected to the left and right sides of the bellows cover 4, which are the left spherical pad 3 and the right spherical pad 5 respectively. The spherical surfaces of the left and right spherical pads 3 and 5 deviate from each other. The bellows 4 includes a thin-walled annular belt part 8, a bellows locking part 9 and a concertina positioning part 10, the two bellows locking parts 9 and the concertina positioning part 10 are connected to form a U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com