Process for producing ceramic lamp

A production process and ceramic technology, which is applied in the field of ceramic lamp production process, can solve the problems of monotonous visual effect, monotonous structure and shape, complicated and complicated production process, etc., and achieve flexible and diverse styles, bold and novel designs, and expand the limit length. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

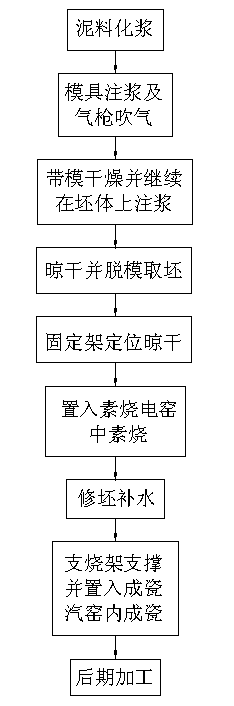

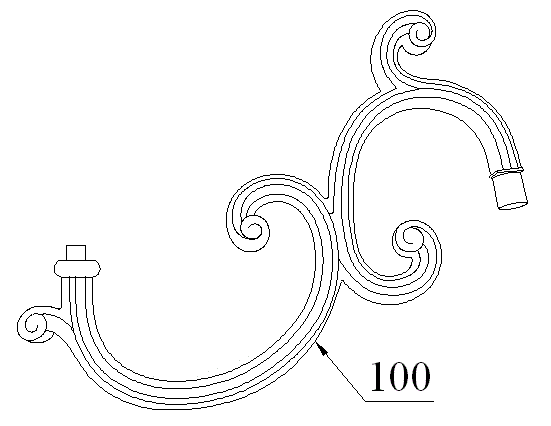

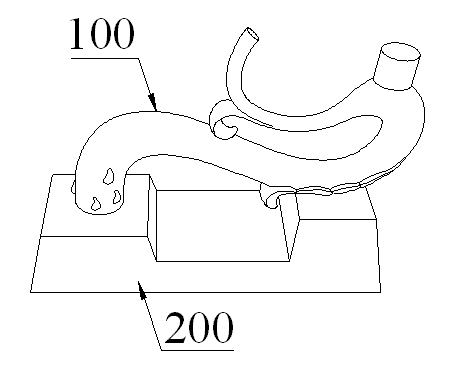

[0023] refer to Figure 1 to Figure 3 , an embodiment of the production process of a ceramic lamp of the present invention is proposed. The ceramic lamp includes a ceramic central axis, a lamp arm mounting plate arranged on the ceramic central axis, and a ceramic lamp arm mounting plate fixed on the lamp arm mounting plate and extending outward. The lamp arm 100, the light source tray located on the upper end of the ceramic lamp arm 100, the luminous body installed on the light source tray, the ceramic central axis, the lamp arm mounting plate, the ceramic lamp arm 100, and the light source tray are all ceramic structures made of ceramics.

[0024] The production process of the ceramic structure is as follows:

[0025] A. Mud slurry: The weight ratio formula of porcelain clay raw materials is as follows: 89% kaolin, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap