Mining anti-explosion coal bunker gas automatic emission control device

A mine explosion-proof and automatic discharge technology, applied in gas discharge, mining equipment, pump control and other directions, can solve the problems of low safety, economic loss, personnel suffocation, etc., to reduce hidden safety hazards, good energy saving effect, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

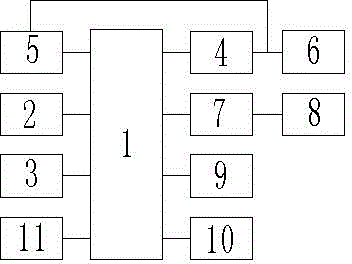

[0013] Such as figure 1 As shown, the mine explosion-proof coal bunker gas automatic emission control device includes: a processor unit 1, a gas concentration acquisition unit 2 and a power supply unit 3, and the device also includes: a fan operation state control unit 4, and a fan operation state monitoring unit 5 , fan control equipment 6, non-intrinsically safe electrical equipment control unit 7 and non-intrinsically safe electrical switch unit 8; The signal input end of the processor unit 1 is also electrically connected with: an alarm unit 9 and a display unit 10; the signal output end of the processor unit 1 is connected with the fan operating state control unit 4 and the non-local The signal input end of the electric equipment control unit 9 is electrically connected, and the output end of the fan operation state control unit 4 is respectively electrically connected with the signal input end of the fan operation state monitoring unit 5 and the fan control device 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com