Stepping mechanism hydraulic station

A technology of stepping mechanism and hydraulic station, applied in the field of hydraulic station, can solve the problems of non-adjustable movement speed, unstable movement, large space occupation, etc., and achieve the effect of compact structure, stable movement and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

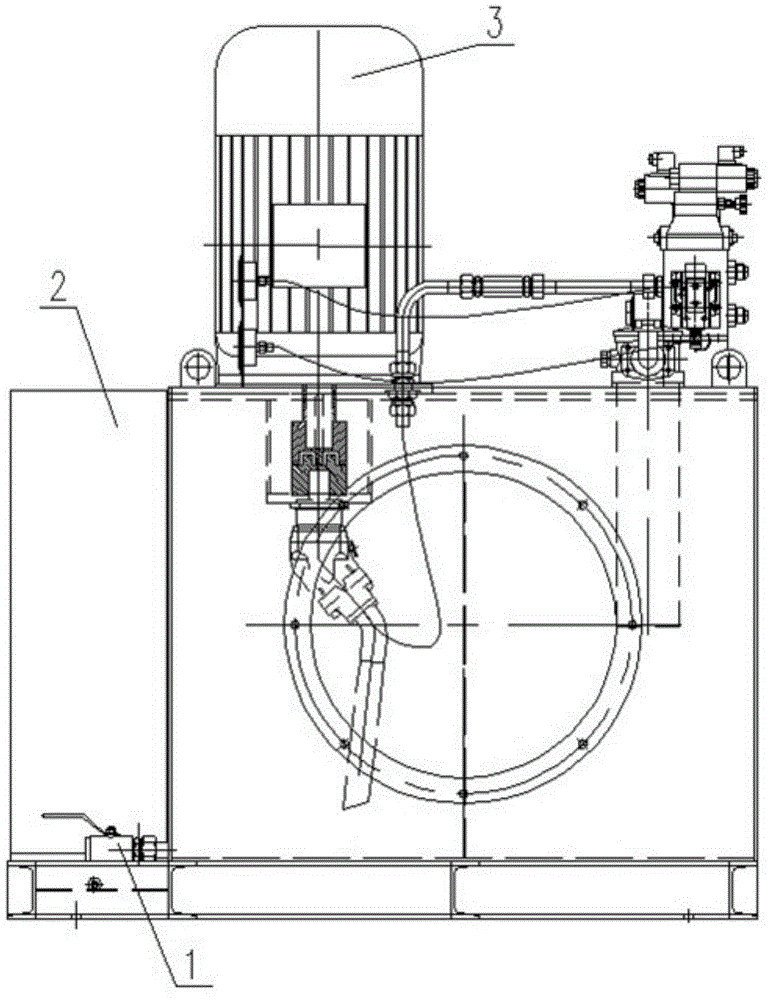

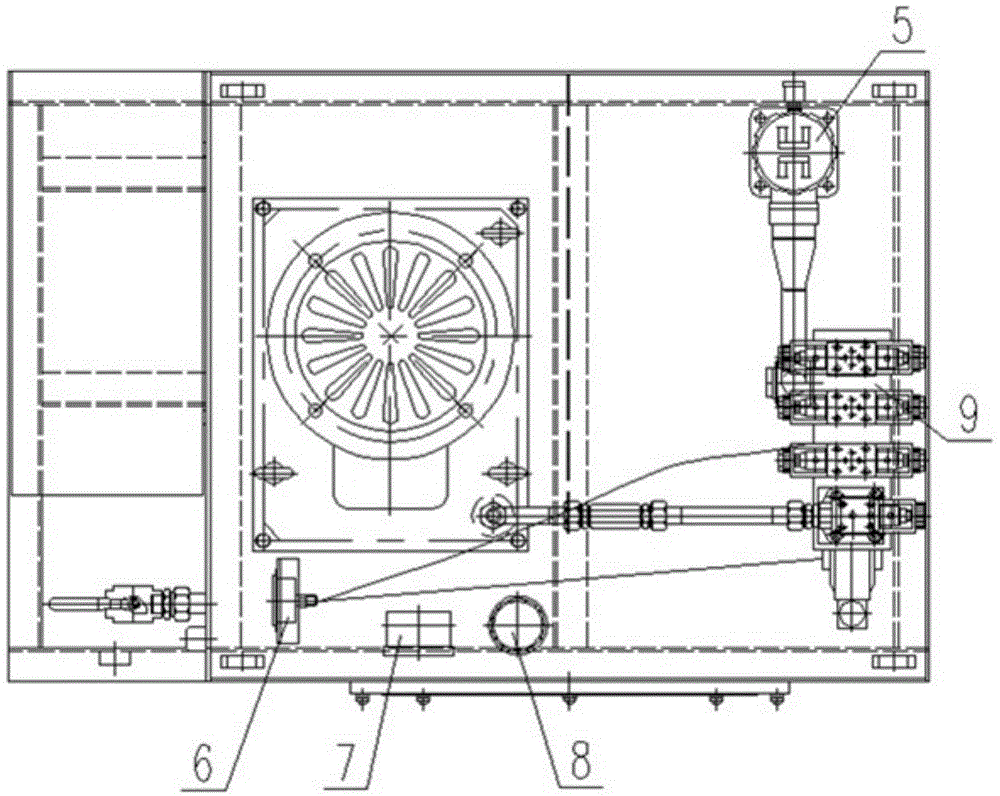

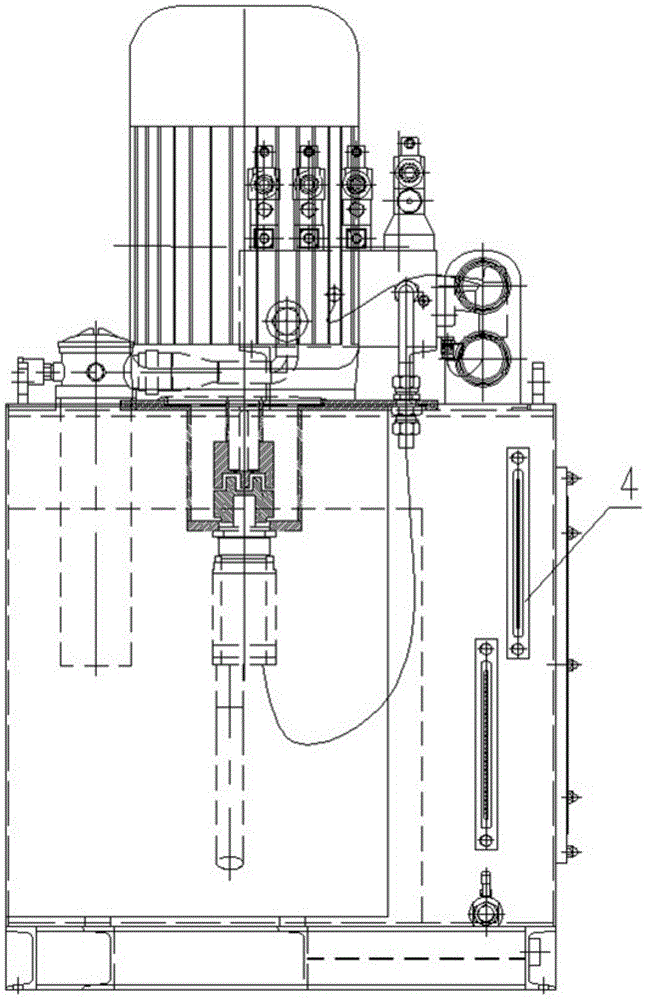

[0015] Such as Figure 1-Figure 8 As shown, the hydraulic station of the stepping mechanism includes an electric control cabinet 2, a motor pump group 3, an oil return filter 5, an air filter 8, a hydraulic valve group 9 and a fuel tank 10, and the motor pump group 3, Oil return filter 5, pressure gauge assembly 6, bimetallic thermometer 7, air filter 8, hydraulic valve group 9, motor pump group 3 includes motor and quantitative plunger pump, motor pump group 3 is connected with hydraulic valve group 9 , the hydraulic valve group 9 is connected to the oil return filter 5, and the pressure gauge assembly 6 includes a pressure measuring joint 11, a pressure measuring hose 12, and a pressure gauge 13 connected in sequence; an oil drain ball valve 1 and an electric control cabinet 2 are installed on the side of the oil tank 10 , liquid level liquid thermometer 4; Hydraulic valve group 9 comprises low-pressure ball valve 14, one-way valve 15, electromagnetic overflow valve 16, one-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com