Microwave thermal excitation system used for detecting or repairing damages of composite material and thermal excitation method of microwave thermal excitation system

A composite material and damage detection technology, which is applied in the direction of material defect testing, etc., can solve the problems of affecting the detection and repair rate, generating sparks, and inability to implement microwave in-situ heating, etc., achieving high uniformity, high heating efficiency, and avoiding direct effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

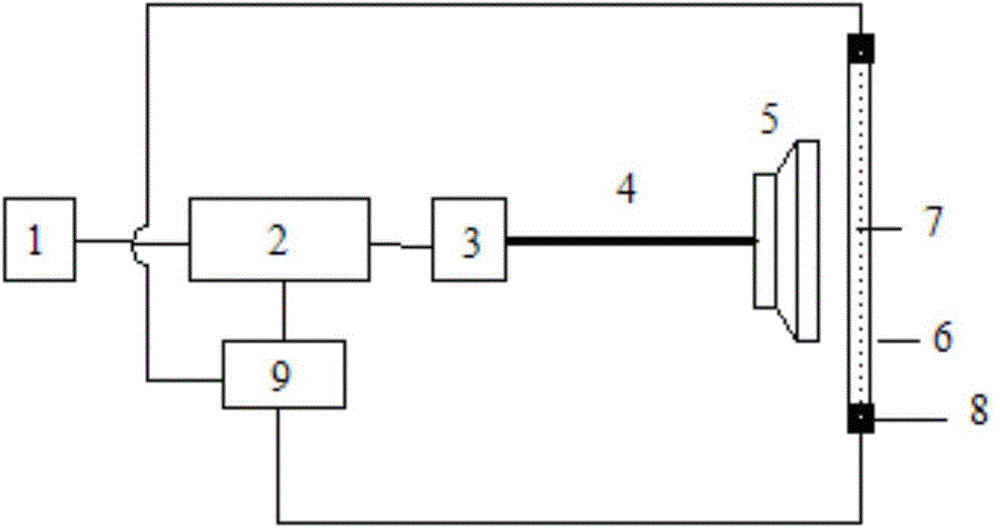

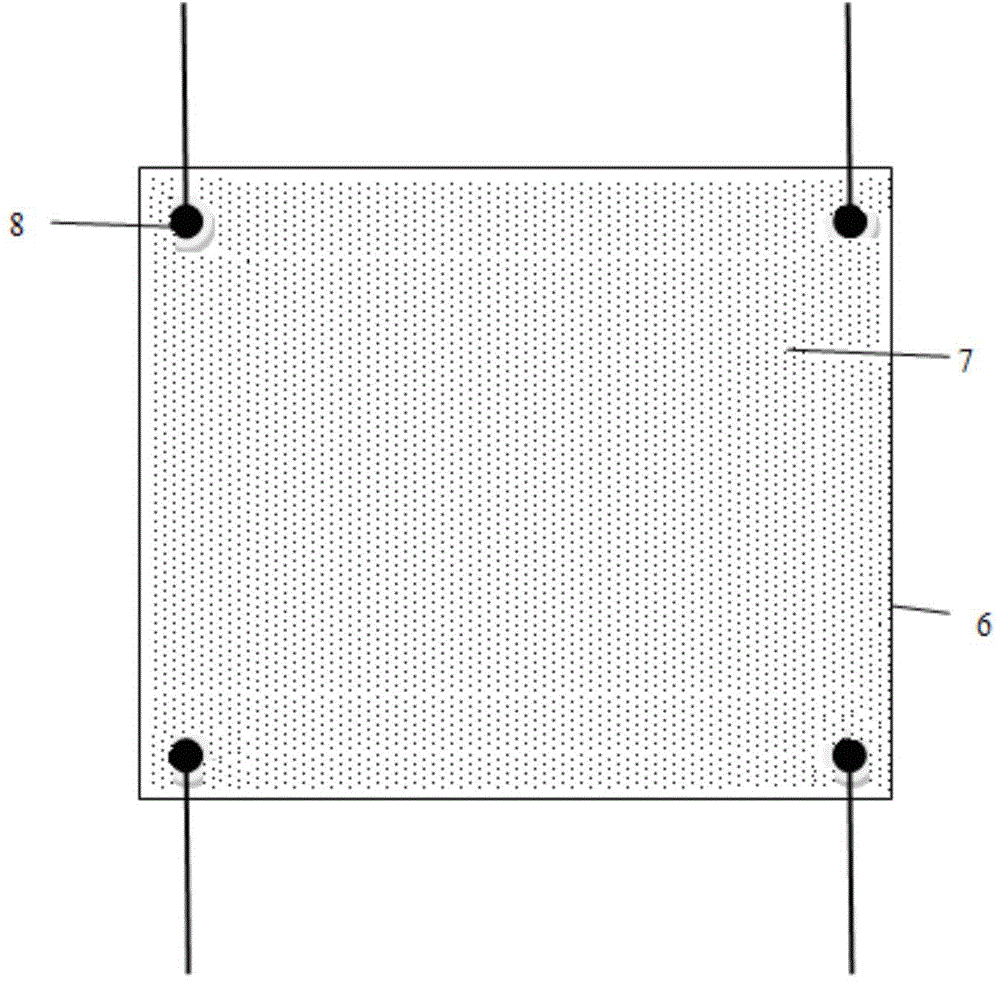

[0024] Such as Figure 1-2 As shown, a microwave thermal excitation system for damage detection or repair of composite materials, including a microwave power supply 1, a current controller 2, a magnetron 3, a waveguide 4, a microwave radiation antenna 5, and a microwave radiation The microwave energy converter provided by the antenna 5, the current controller 2 and the microwave controller 9 are connected by wires, the microwave energy converter is provided with several temperature sensors 8, and the temperature sensors 8 are connected to the microwave controller 9 by wires. The microwave energy converter includes a silicone rubber matrix 6 and microwave absorbing materials 7 uniformly distributed in the silicone rubber matrix 6 .

[0025] The method for thermally actuating composite materials with the above-mentioned microwave thermal actuation system comprises the following steps:

[0026] Step (1), cleaning the surface of the area to be excited on the excited composite mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com