Creeping wave detection method for crack defects of austenitic stainless steel pipe for power station boiler

A technology for austenitic stainless steel and power plant boilers, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, which can solve the problems of large initial wave occupation and difficulty of shear wave oblique probes, and achieve the effect of convenient operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

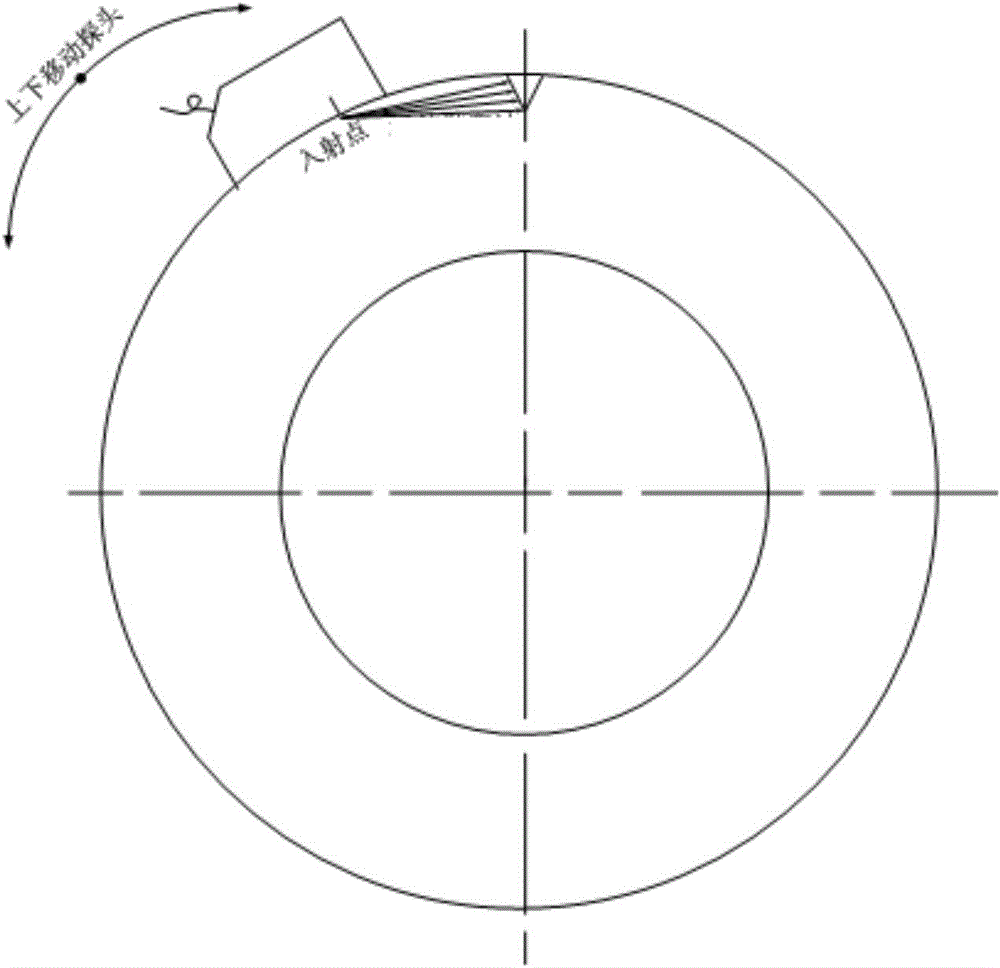

[0018] refer to figure 1 , the creeping wave detection method of the austenitic stainless steel pipe crack defect of the utility boiler of the present invention comprises the following steps:

[0019] 1) Select the climbing frequency emitted by the climbing wave probe, and then grind the bottom of the wedge into an arc surface that matches the position to be measured of the austenitic stainless steel pipe used in the utility boiler;

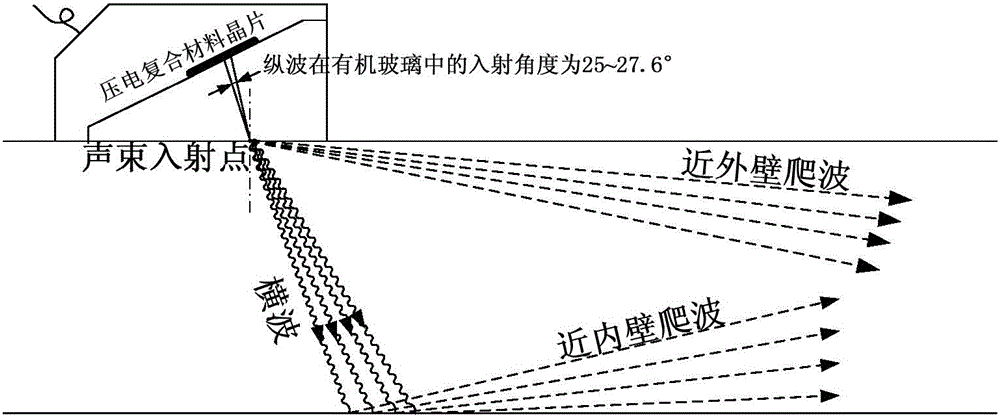

[0020] 2) The climbing wave probe emits climbing waves, glue the climbing wave probe to the wedge, adjust the climbing wave probe so that the incident angle of the longitudinal wave emitted by the climbing wave probe in the wedge is 25-27.6°;

[0021] 3) Fit the curved surface at the bottom of the wedge bonded with the creeping wave probe to the position to be tested of the austenitic stainless steel pipe used for the power plant boiler,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com