Stator winding structure of brushless coreless disk permanent magnetic motor and motor with the stator winding structure

A permanent magnet motor and stator winding technology, applied in the shape/style/structure of winding conductors, etc., can solve the problems of difficult to accurately design motor power, low utilization rate of magnetic field, and high utilization rate of magnetic field, and achieve high utilization rate of electromagnetic field, The effect of maximizing the sweep area and increasing the strength of the main shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

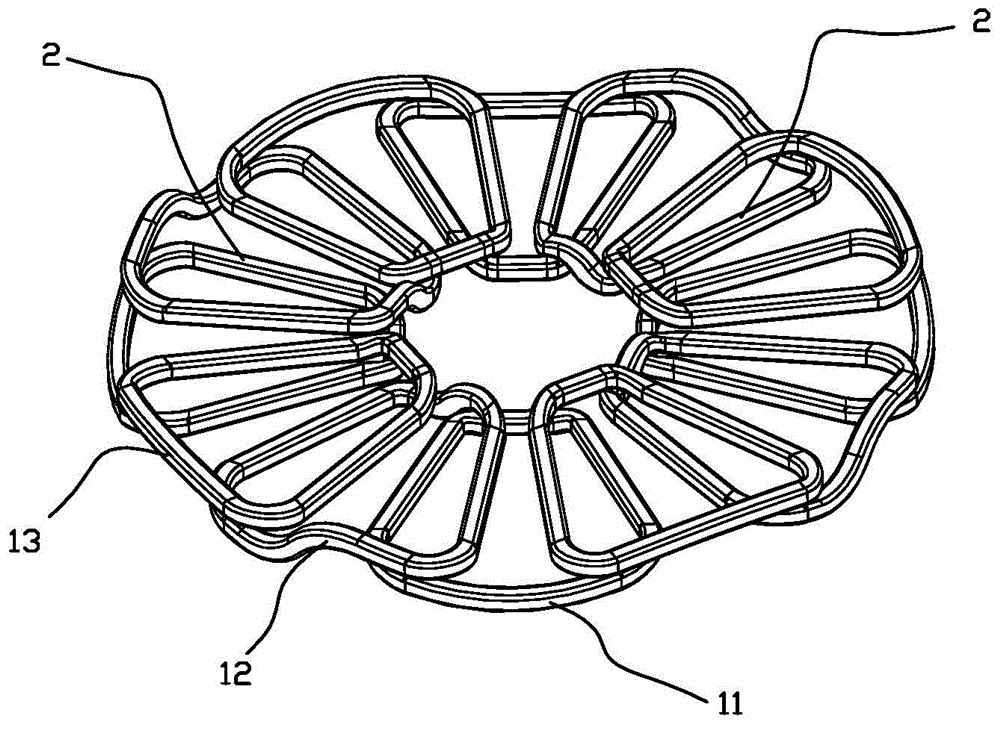

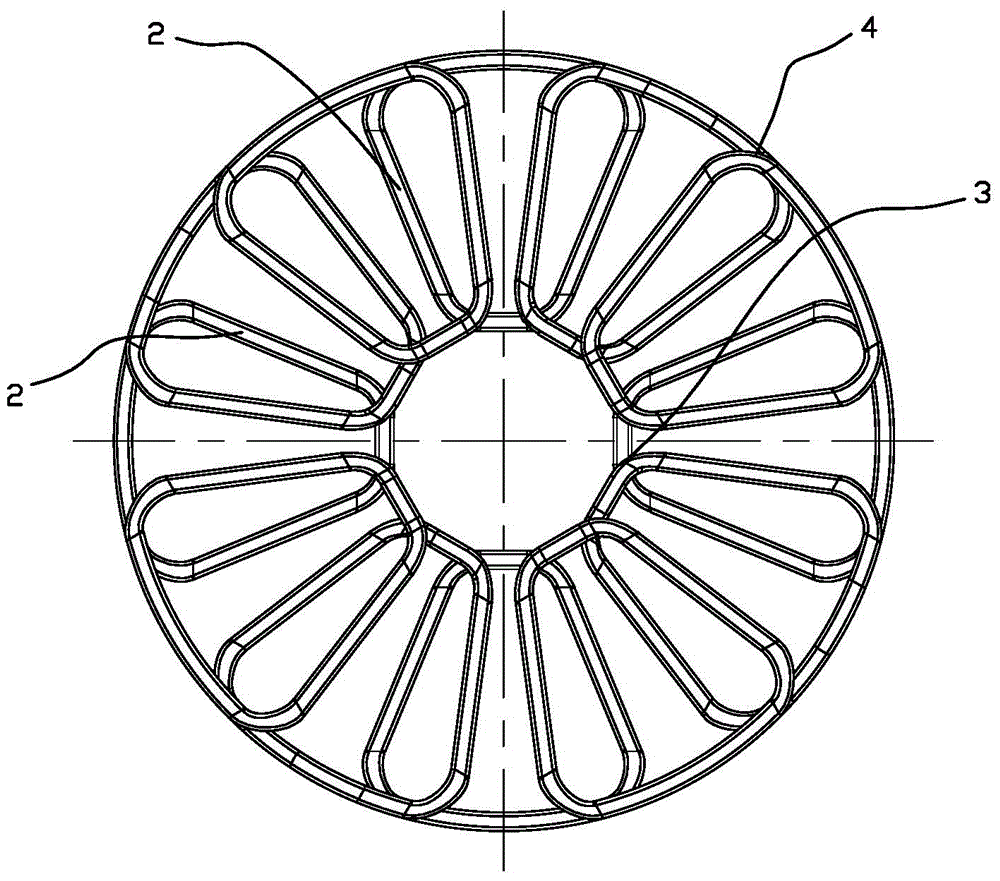

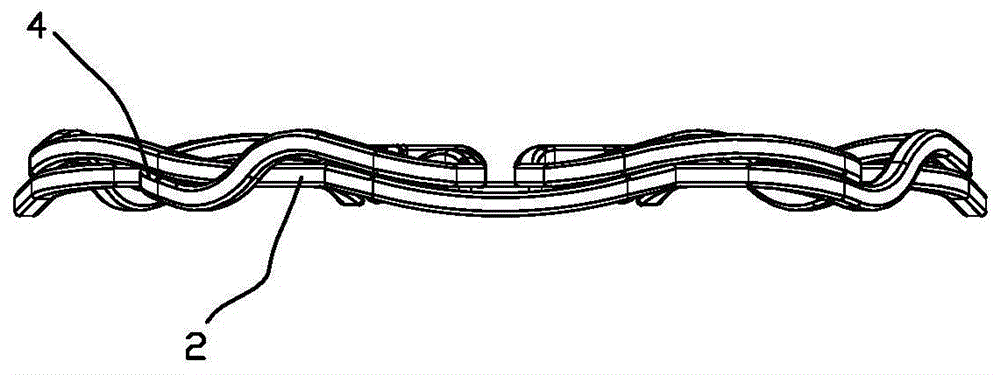

[0036] Embodiment 1: as figure 1 , Figure 4 As shown, a stator winding structure of a brushless iron-coreless disc permanent magnet motor, the winding structure includes four sets of unit coil groups 1 with staggered angles and sequentially stacked downwards in the clockwise direction to form a closed ring structure, Each unit coil group 1 includes three coils with staggered angles and sequentially stacked upwards in the clockwise direction, as shown in Figure 5 As shown, the three coils are sequentially the first coil 11, the second coil 12 and the third coil 13 from bottom to top. The ends make the coils constitute the inner and outer invalid sides of the closed ring structure, and the included angles formed by the two magnet scanning sides of each coil are set to be the same. Such as Figure 6 , Figure 7 , Figure 8 As shown, the outer invalid edge on the first coil 11 corresponds to the first outer invalid edge 111, the inner invalid edge on the first coil 11 corre...

Embodiment 2

[0043] Embodiment 2: as Figure 17 As shown, each coil includes four pairs of magnet scanning sides 2 that are straight segments and inner and outer ineffective sides connected to the inner and outer ends of the magnet scanning sides 2 so that the coil forms a closed ring structure, and the outer ineffective sides are arranged on each pair of magnet scanning sides. The outer end of the side is used for the connection of the outer end of the pair of magnet scanning sides, and the inner invalid side is arranged on the inner end of the magnet scanning side, and is used for the connection of the inner end of the adjacent magnet scanning side. In this embodiment, only Three coils with four pairs of magnet scanning sides are required to be stacked. These three coils are the first coil 11, the second coil 12 and the third coil 13 from bottom to top, as Figure 18 , Figure 19 , Figure 20 , Figure 21 As shown, the angle formed by each pair of magnet scanning sides on the first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com