Sugarcane Tail Cutting Machine

A sugarcane and tail machine technology, applied in cutters, harvesters, agricultural machinery and implements, etc., can solve the problem of not being able to cut the tail of the sugarcane stem one by one, and achieve the effect of ensuring the quality of cutting tips, high cutting rate and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with accompanying drawing implementation:

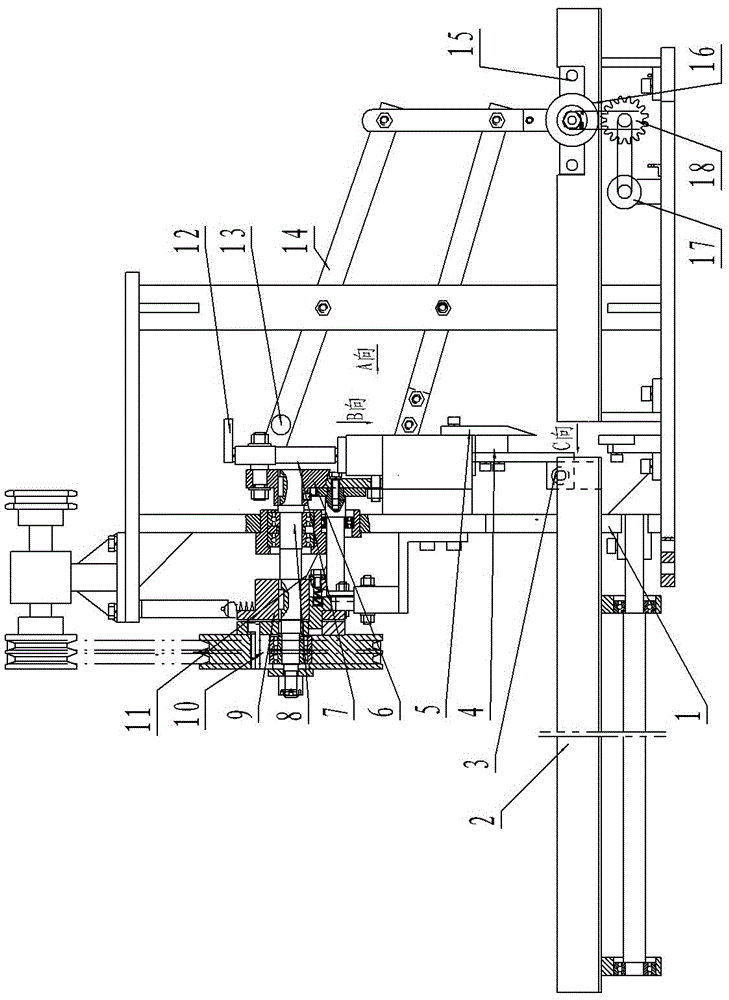

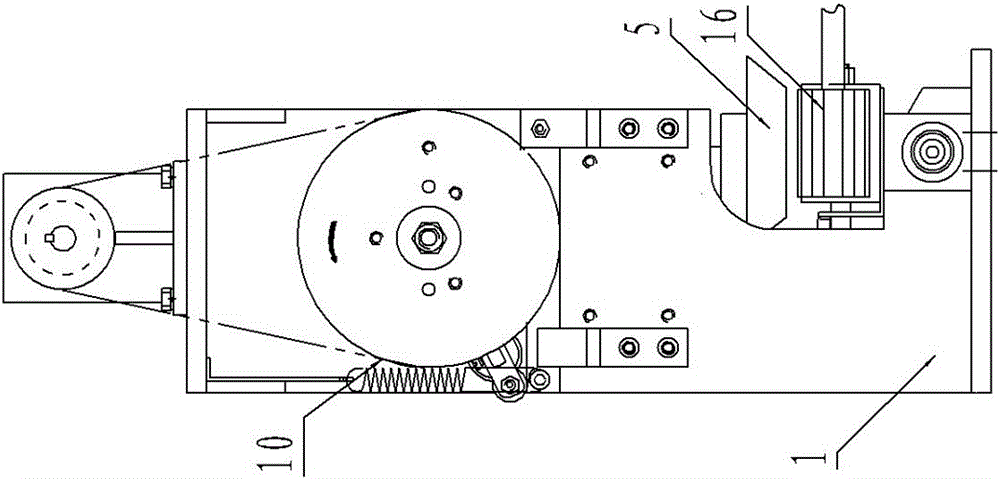

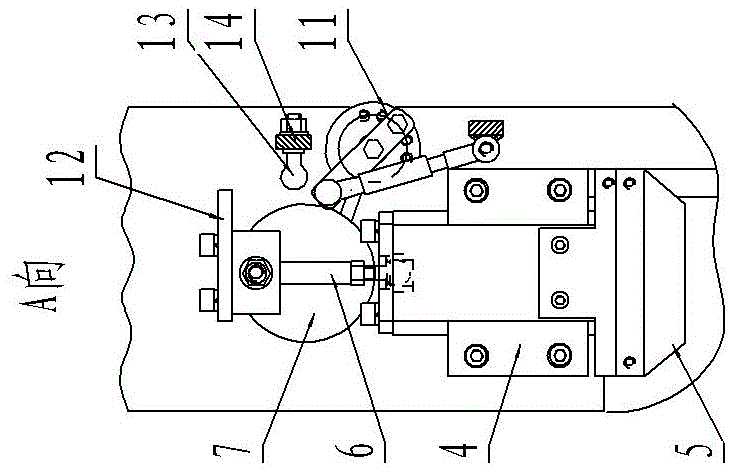

[0022] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The sugarcane tail cutting machine shown is composed of frame 1, cane stalk bearing groove 2, spring protrusion 3, knife rest 4, cutting knife 5, crank 6, connecting rod 7, rotating shaft 8, clutch 9, power transmission mechanism 10, Clutch control parts 11, pressing plate 12, roller 13, linkage 14, pressing wheel mounting plate 15, pressing wheel 16, power machine 17, conveying driving wheel 18, inclined block 19, extension spring 20, hinge shaft 21 etc. constitute. The frame 1 is provided with a sugarcane conveying passage, and is provided with a conveying drive wheel 18 on the sugarcane conveying passage; a blade stroke is arranged to pass through the cutting knife 5 of the sugarcane conveying passage, and the knife rest 4 of the cutting knife 5 is installed on the machine On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com