Processing method of tea lozenge

A processing method and technology of tea lozenges, which are applied in the processing field of tea lozenges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

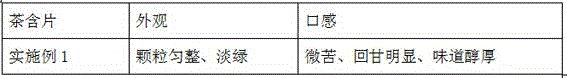

Embodiment 1

[0023] Raw materials: 6 kg of green tea and 2 kg of rattan tea are fully mixed, crushed and sieved to obtain 16 meshes of broken tea, and the hygienic indicators such as pesticide residues, heavy metals and microorganisms meet the relevant provisions of the national standards of the People's Republic of China.

[0024] Extraction: The tea-water ratio was 1:12, the extraction temperature was 45°C, and the extraction time was 35 min, and the extraction was carried out twice. The two extractions were mixed and filtered to obtain 150 L of tea extract with better flavor.

[0025] Compound enzyme treatment: The obtained extract was subjected to compound enzyme treatment, the amount of tannase added was 20 g (accounting for 1.10% of the solid content of the extract), and the amount of amylase added was 12 g (accounting for 0.66% of the solid content of the extract). %), the compound enzyme treatment temperature was 47°C, and the enzymolysis was carried out for 120 min to obtain 145 L ...

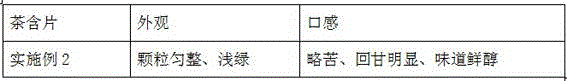

Embodiment 2

[0033] Raw materials: 6 kg of green tea, 2 kg of yellow tea and 2 kg of rattan tea are fully mixed, crushed and sieved to obtain 20 meshes of broken tea, and the hygienic indicators such as pesticide residues, heavy metals and microorganisms meet the relevant provisions of the national standards of the People's Republic of China.

[0034] Extraction: The tea-water ratio was 1:10, the extraction temperature was 65°C, and the extraction time was 30 min, and the extraction was carried out twice. The obtained two extracts were mixed and filtered to obtain 172 L of tea extract with better flavor.

[0035] Compound enzyme treatment: The obtained extract was subjected to compound enzyme treatment, the amount of tannase added was 23 g (accounting for 0.92% of the solid content of the extract), and the amount of amylase added was 20 g (accounting for 0.80% of the solid content of the extract). %), the compound enzyme treatment temperature was 40°C, and the enzymolysis was carried out fo...

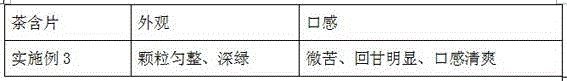

Embodiment 3

[0043] Raw materials: 2 kg of green tea, 2 kg of oolong tea, 2 kg of yellow tea, 2 kg of black tea and 2 kg of rattan tea are fully mixed, crushed and sieved to obtain 40 meshes of crushed tea, and the hygienic indicators such as pesticide residues, heavy metals and microorganisms meet the standards of the Chinese people Relevant provisions of the national standards of the Republic.

[0044] Extraction: The tea-water ratio was 1:30, the extraction temperature was 50°C, and the extraction time was 28 min, and the extraction was carried out twice. The obtained two extracts were mixed and filtered to obtain 265 L of tea extract with better flavor.

[0045] Compound enzyme treatment: The obtained extract was subjected to compound enzyme treatment, the amount of tannase added was 29 g (accounting for 1.16% of the solid content of the extract), and the amount of amylase added was 12 g (accounting for 0.48% of the solid content of the extract). %), the compound enzyme treatment tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com