Control method of bulk density of abc dry powder fire extinguishing agent

A technology of dry powder fire extinguishing agent and control method, applied in fire protection equipment and other directions, can solve the problems of difficult filling, unfavorable quality management of ABC dry powder fire extinguishing agent, and decreased capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

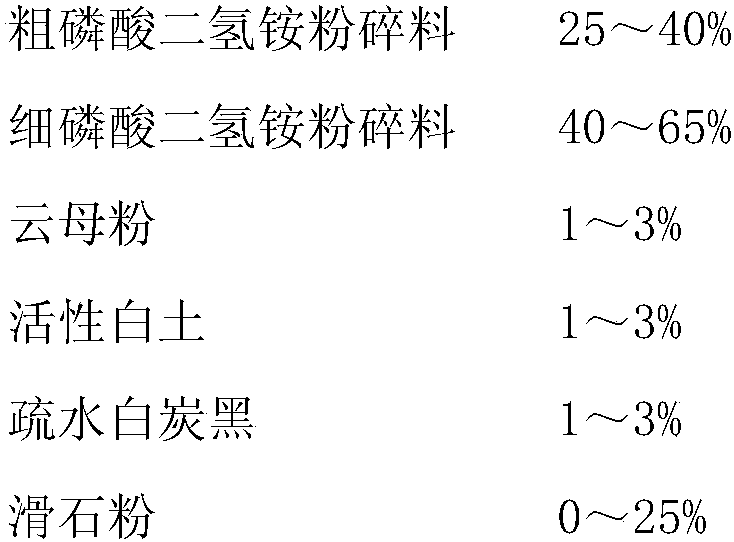

[0029] Bulk density control method of 90% ABC dry powder fire extinguishing agent

[0030] 1) Divide the raw materials of ammonium dihydrogen phosphate into two groups, and use LF-60 built-in graded ultrafine pulverizer to pulverize the two groups of raw materials to control the "particle size distribution". A group of pulverization to obtain fine ammonium dihydrogen phosphate pulverized material; among them, the host machine adopts stepless speed change, and the classifier and feeder adopt electromagnetic speed change, as follows:

[0031] ① "Particle size distribution" control of crude ammonium dihydrogen phosphate pulverized material: grind the raw material of ammonium dihydrogen phosphate according to the host frequency of 38Hz, classifier speed of 150r / min, and feeder speed of 1200r / min to obtain crude ammonium dihydrogen phosphate pulverized material, and then press National standard GB4066.1-2004 article 5.7 method, test the "particle size distribution" of crude ammoniu...

Embodiment 2-3

[0049] The detection method of embodiment 2-3 " particle size distribution " and product bulk density is also the same.

[0050] Table 1: Test results of raw material particle size distribution and crushed weight, taking one ton of product as an example (the 0.250mm part has been removed)

[0051]

[0052]

[0053] According to the national standard GB4066.1-2004 clause 5.2 method, the 90% ABC dry powder fire extinguishing agent prepared above was tested for bulk density, and the bulk density was 0.93g / ml.

Embodiment 2

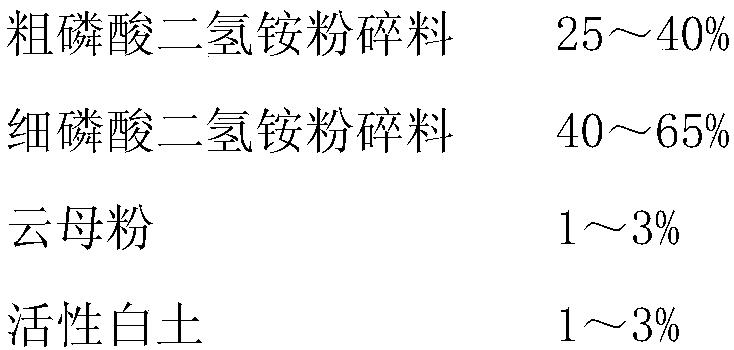

[0055] Bulk density control method of 80% ABC dry powder fire extinguishing agent

[0056] 1) Divide the raw materials of ammonium dihydrogen phosphate into two groups, and use LF-60 built-in graded ultrafine pulverizer to pulverize the two groups of raw materials to control the "particle size distribution". A group of pulverization to obtain fine ammonium dihydrogen phosphate pulverized material; among them, the host machine adopts stepless speed change, and the classifier and feeder adopt electromagnetic speed change, as follows:

[0057] ① "Particle size distribution" control of crude ammonium dihydrogen phosphate pulverized material: grind the raw material of ammonium dihydrogen phosphate according to the host frequency of 37Hz, classifier speed of 125r / min, and feeder speed of 1200r / min to obtain crude ammonium dihydrogen phosphate pulverized material, and then press National standard GB4066.1-2004 article 5.7 method, test the "particle size distribution" of crude ammoniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com