Acoustic vibration brush and cleaning method adopting acoustic vibration brush

A technology of sonic vibration and vibrating rod, which is applied in the cleaning method using liquid, cleaning method using tools, cleaning method and utensils, etc. It can solve the problem of easily damaged ceramic substrates or radar electronic components, unclean cleaning, poor consistency, etc. problems, to prevent uneven cleaning, improve brushing efficiency, and reduce operational fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

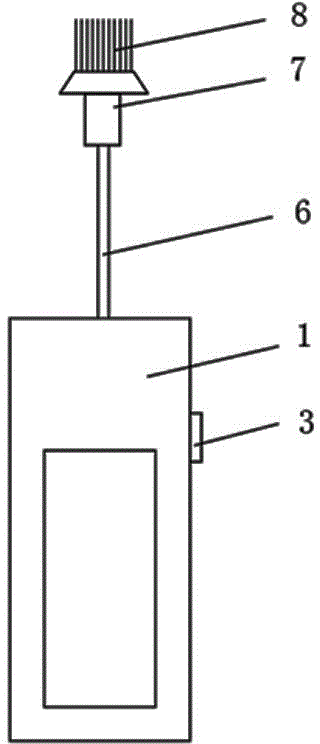

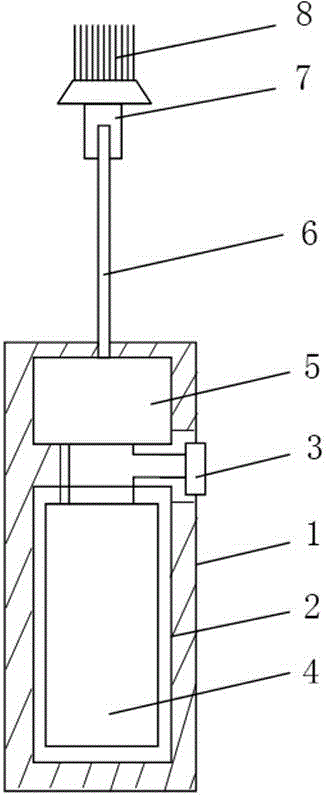

[0027] see figure 1 , a sonic vibration brush, including a handle 1, a rechargeable battery compartment 2, a switch 3, a rechargeable battery 4, a sonic transducer 5, a vibrating rod 6, a brush head sleeve 7 and bristles 8.

[0028] Among them: see figure 2 , the handle 1 is a hollow cylinder. One end of the cavity of the handle 1 is provided with a rechargeable battery compartment 2 , and a rechargeable battery 4 is arranged in the rechargeable battery compartment 2 .

[0029] see figure 2 , the other end of the cavity of the handle 1 is provided with an acoustic wave transducer 5 . The ultrasonic transducer 5 is responsible for converting the electrical energy provided by the rechargeable battery 4 into sound wave vibration energy. The vibration frequency of the acoustic wave transducer 5 is 200 Hz-700 Hz.

[0030] see figure 1 A switch 3 is provided on the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com