Balance supporting auto-alignment device of machine tool

A balanced and automatic technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of increased assembly cycle and production cost, poor machine tool accuracy, large shape and position tolerance, etc., to achieve good cost performance, Improved reliability and wide versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

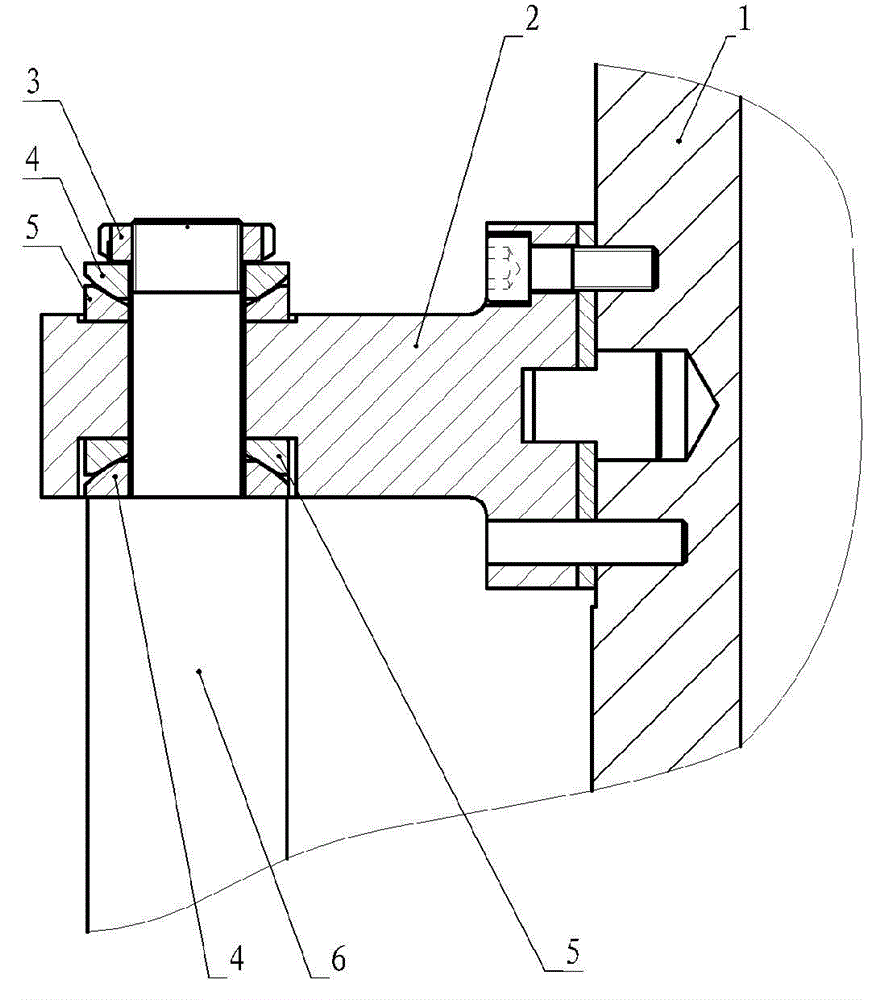

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0013] figure 1 The machine tool balance support automatic alignment device; includes a support seat 2; one end of the support seat 2 is connected with the lifting headstock 1 of the machine tool through bolts and pins, and the other end is connected with the boss at the end of the piston rod 6 in the oil cylinder. The cylinder body of the oil cylinder is fixedly installed on the sliding seat of the lifting headstock 1; the connection between the boss at the end of the piston rod 6 and the support seat 2 is set with an upper self-aligning spherical washer 4 and a lower self-aligning spherical washer 5; One side of the upper self-aligning spherical washer 4 is a plane, and the other side is a convex spherical surface; one side of the lower self-aligning spherical washer 5 is a plane, and the other side is a concave spherical surface; the lower self-aligning spherical w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com