Grinding head mechanism of a vertical glass edging machine

A glass edging and grinding head technology, which is applied to the parts, grinding heads, and grinding driving devices of grinding machine tools, can solve the problems of inability to achieve grinding, burst glass, and inaccurate positioning, and achieve structural design. The effect of compactness, smooth grinding surface and improved grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

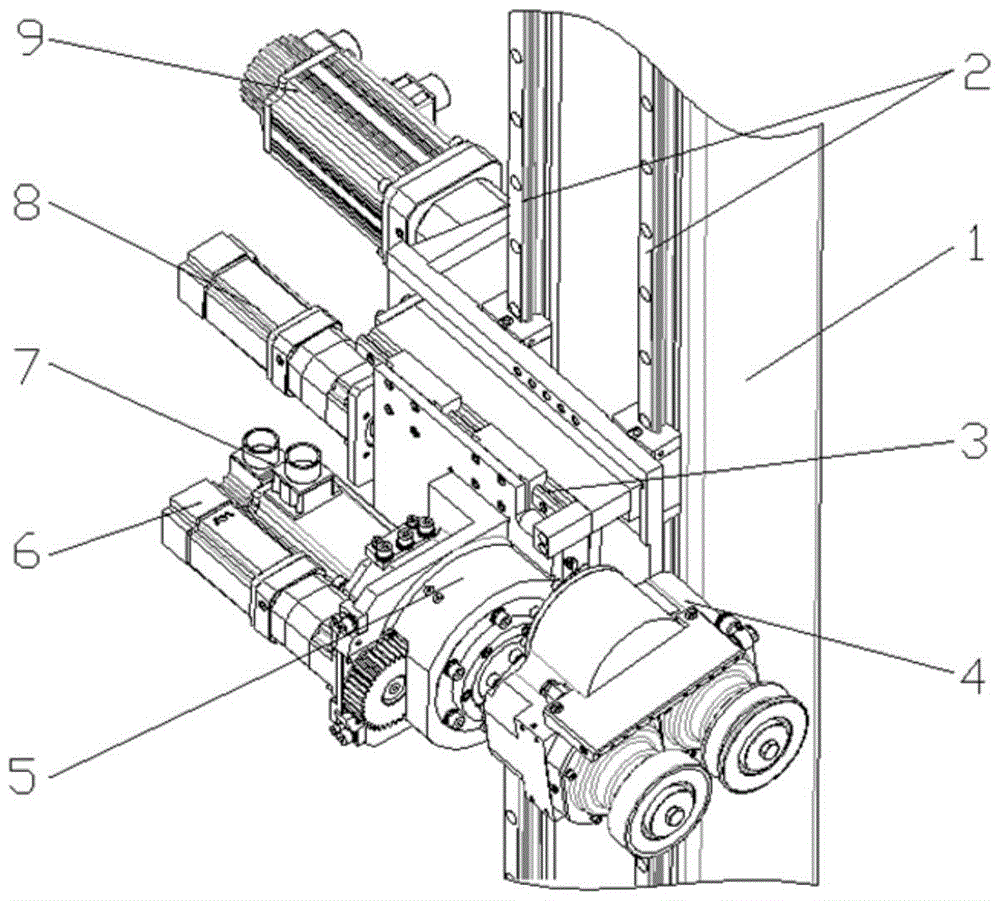

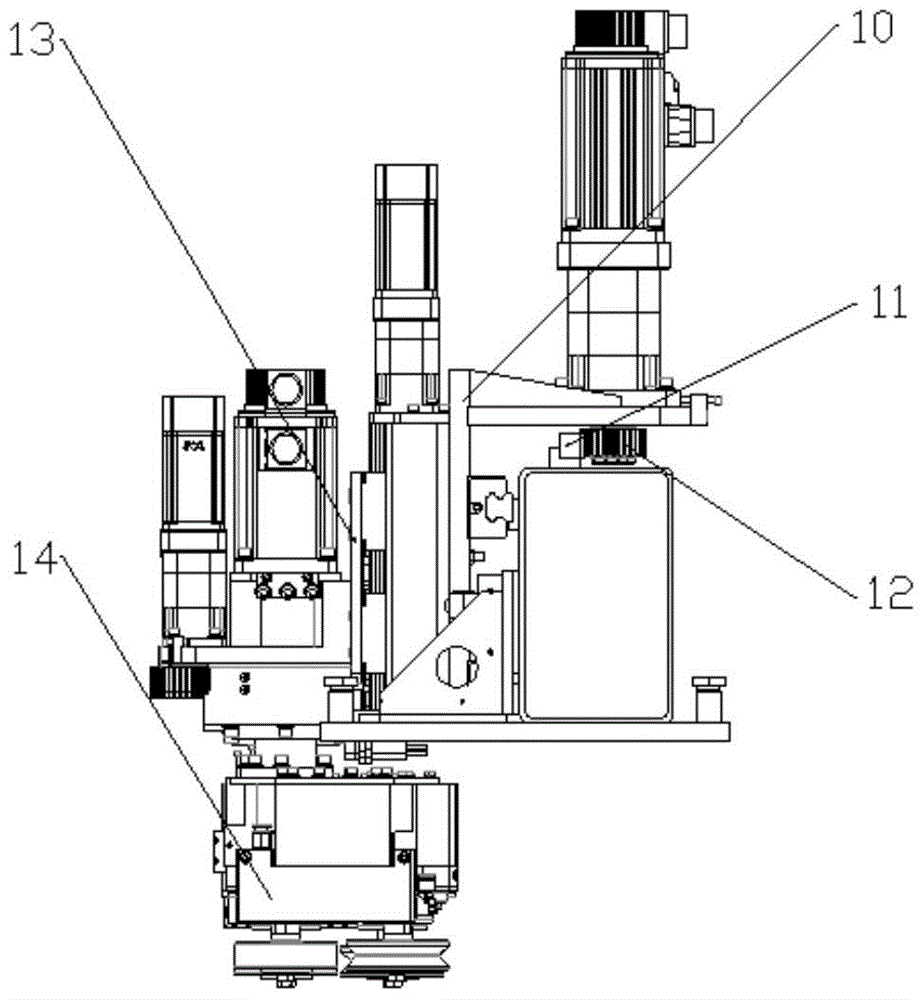

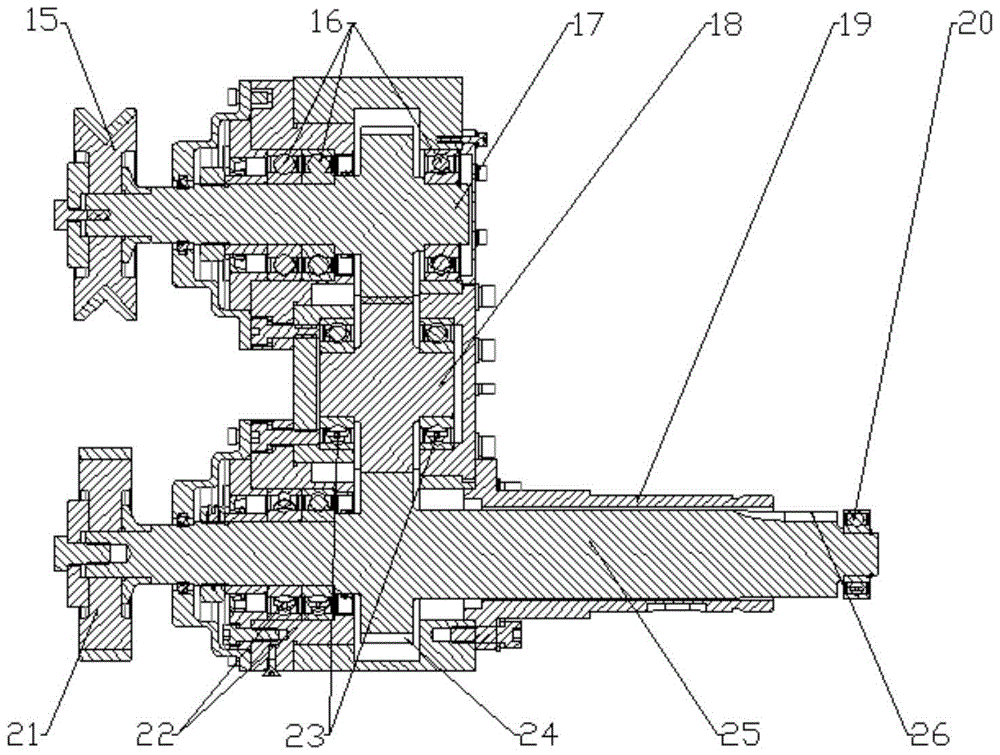

[0027] A grinding head mechanism of a vertical glass edging machine mainly includes a grinding wheel gear box 4, a grinding wheel group, a grinding wheel group rotation mechanism, a grinding head spindle gear box 5, a grinding head telescopic mechanism and a grinding head moving mechanism. The grinding wheel set is used for grinding the bottom edge and chamfer of the glass, including the bottom edge grinding wheel 21, the chamfering grinding wheel 15, the long gear shaft 25, the short gear shaft 17, the intermediate gear shaft 18, the driving gear 29 of the grinding wheel set and the high-speed rotation of the grinding wheel set servo motor7. The grinding wheel group rotation mechanism is used for the rotation of the grinding wheel group to adapt to the horizontal and vertical sides of the glass, including the grinding head rotating base plate 13, the rotating shaft sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com