Carbonitriding process for medium-large thin-wall bearing in high-carbon chromium bearing steel

A high-carbon chromium bearing steel, carbonitriding technology, applied in the direction of metal material coating process, manufacturing tools, furnace types, etc., can solve problems such as large heat treatment deformation, achieve small deformation, reduce grinding amount, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] s1. Carbonitriding: Put a batch of 25 bearing outer ring products in 25 stations of the rotary hearth furnace at the same time, set the pushing cycle to 504s, heat to 820°C, set the methanol flow rate to 2.5L / h, Nitrogen flow rate 2.0m 3 / h, natural gas flow rate 0.3m 3 / h, ammonia gas flow rate 0.2m 3 / h, carbon potential 1.05%.

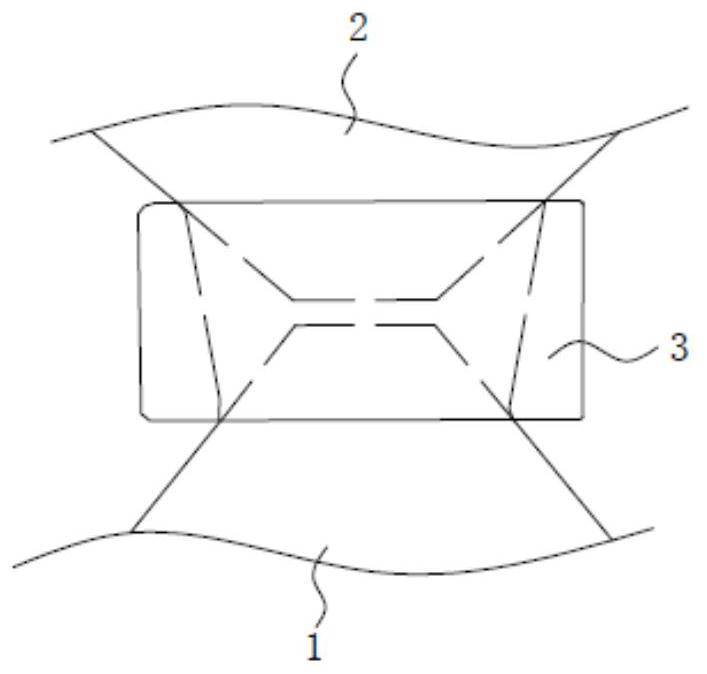

[0045] s2. Die quenching: After the carbonitriding heating of the product, the furnace door is automatically pushed out and transferred to the lower mold 1, then the upper mold 2 is pressed down by the cylinder, and the upper mold 2 presses the inner chamfer of the upper end surface of the product 3 and enters the oil tank for quenching ,Such as image 3 shown. The upper mold 2 has a taper of 45° and a size of 280mm, and the lower mold 1 has a taper of 45° and a size of 260mm. The controlled quenching pressure is 0.50MPa, the quenching oil temperature is 60°C, and the quenching time is 180s.

Embodiment 2

[0048] The difference from Example 1 is: s1, carbonitriding: set the pushing cycle to 648s, and heat to 830°C, the methanol flow rate is 3L / h, and the nitrogen flow rate is 2.5m 3 / h, natural gas flow rate 0.5m 3 / h, ammonia gas flow rate 0.3m 3 / h, carbon potential 1.15%.

[0049] s3. Tempering: Control the tempering temperature to 220°C and the tempering time to 4h.

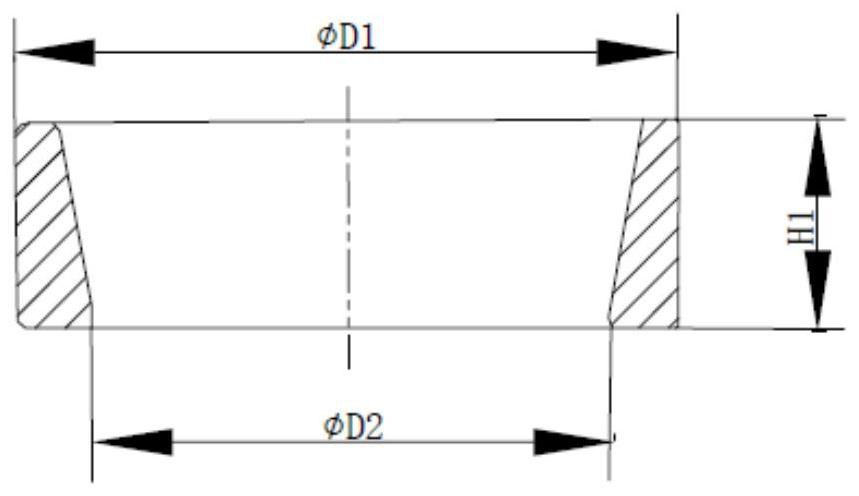

[0050] get as figure 1 Bearing outer ring products shown.

Embodiment 3

[0052] The difference from Example 2 is that the taper of the upper mold is 45°, the size of the upper mold is 210mm, the taper of the lower mold is 30°, and the size of the lower mold is 210mm.

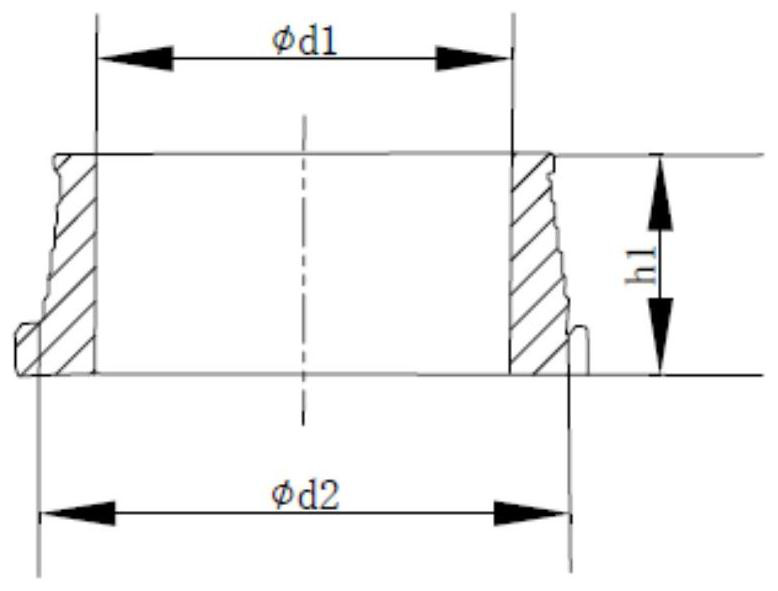

[0053] get as figure 2 Bearing inner ring products shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com