Magnetorheological fluid curved surface polishing system

A magnetorheological fluid and curved surface technology, which is applied in the field of magnetorheological fluid curved surface polishing system, to achieve the effect of expanding the application range, uniform surface and uniform processing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0026] Embodiment 1 Polishing of the inner cylindrical surface.

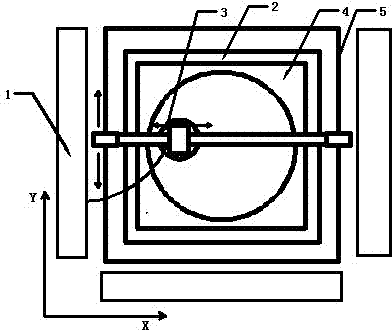

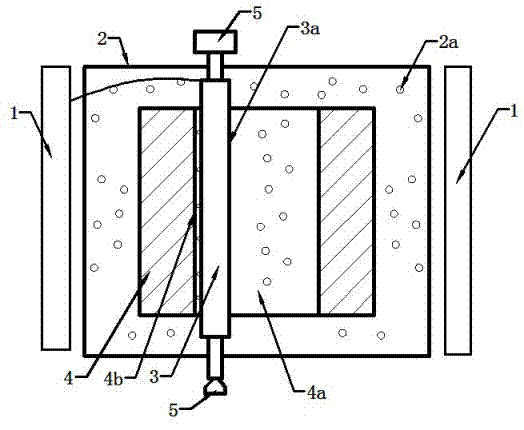

[0027] combine figure 1 , figure 2 , image 3 , when polishing the inner cylindrical surface, first fix the polishing workpiece (4) on the inner cylindrical surface in the polishing pool (2); then add an appropriate amount of magnetorheological fluid mixed with abrasives into the polishing pool (2); Then install the cylindrical polishing axis (3) on the two-coordinate control device (5), and adjust the distance between the polishing axis busbar (3a) and the polishing curved surface busbar (4b) by controlling the movement of the two-coordinate control device (5) in the XY direction Then turn on the magnetic field generating device (1), use the polishing axis (3) as one pole of the magnetic field, and arrange the other pole of the magnetic field evenly in the circumferential direction of the polished workpiece (4) to adjust the magnetic field force. Ensure that each point on the busbar (4b) of the polished cur...

Embodiment approach 2

[0028] Embodiment 2 Polishing of non-revolved surfaces.

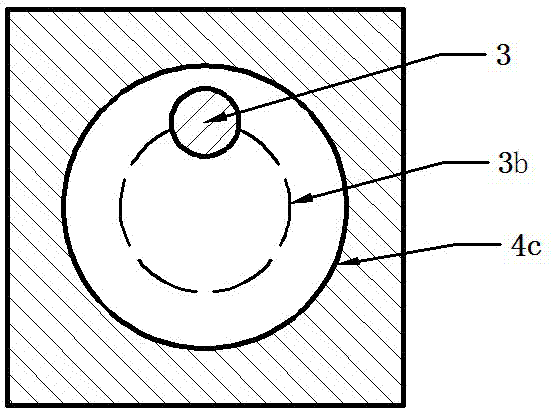

[0029] combine figure 1 , figure 2 , Figure 4 , Figure 5 , the polishing axis (3) whose generatrix is a straight line in Embodiment 1 is replaced with a special polishing axis whose generatrix function curve is consistent with the function curve of the polishing curved surface generatrix (3b). Since the linear velocity of each point of the polishing axis busbar is different, the magnetic field force at each point of the polishing curved surface busbar (4c) needs to be adjusted through the magnetic field generator (1), so that the grinding amount of each point of the polishing curved surface busbar (4c) is consistent. This ensures that the polished curved surface (4a) is uniformly polished, and the rest of the steps are exactly the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com