Connected system of mining vehicle engine and gearbox

A technology for connecting systems and engines, which is applied to vehicle parts, control devices, transportation and packaging, etc., can solve the problems of damage to the engine, transmission system waste of engine output power, transmission shaft shaft weight, etc., to prevent erosion and damage, The effect of reducing the cost of the whole vehicle and improving the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

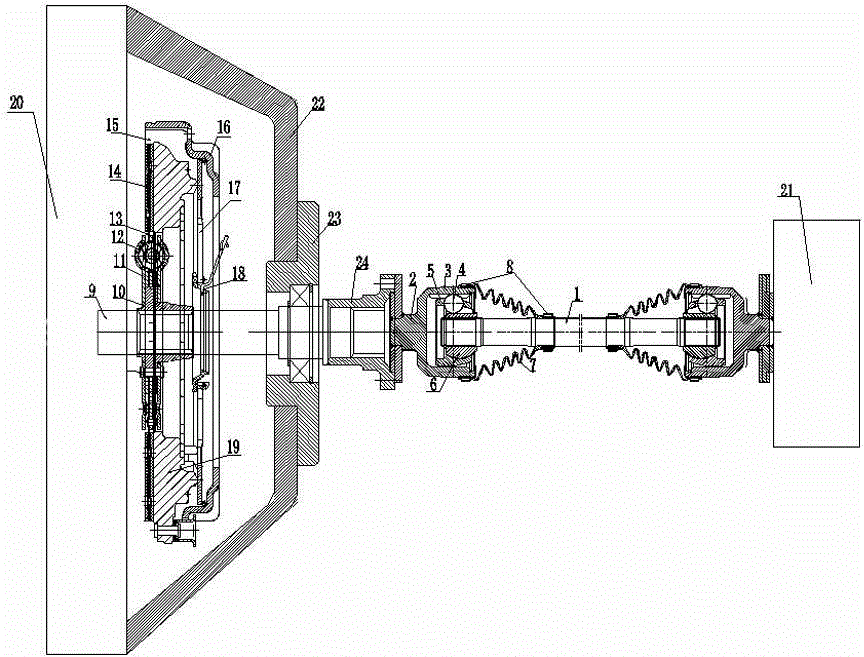

[0025] The present invention as figure 1 , 2 , 3 shown.

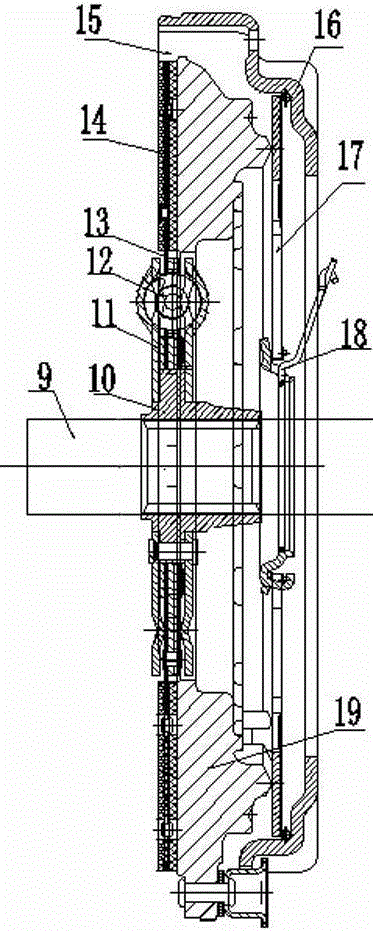

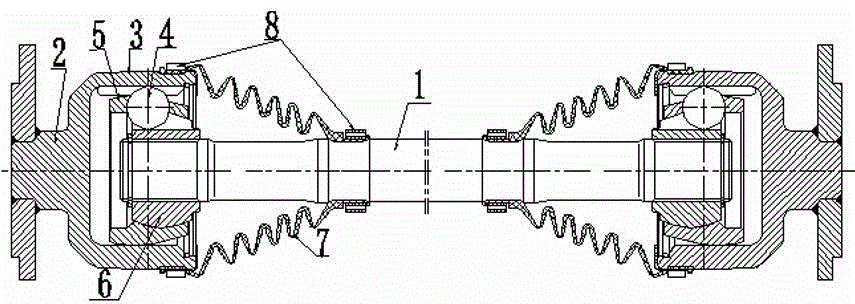

[0026] The connection system between the mining vehicle engine and the gearbox includes the engine 20 and the gearbox 21, the engine 21 is provided with a bearing housing 22, the engine output shaft 9 extends in the bearing housing 22, and the bearing housing 22 is provided with There is a driven plate assembly, and the clutch pressure plate assembly is correspondingly arranged outside the driven plate assembly; the engine output shaft 9 runs through the driven plate assembly and the clutch pressure plate assembly and extends out of the housing 22 of the bearing housing. On the bearing seat 23; the outer bearing seat 23 is connected with a first transmission shaft 24, and between the first transmission shaft 24 and the gearbox 21 is connected with a constant speed transmission system.

[0027] The center of the driven disc assembly is a spline sleeve 10, the spline sleeve 10 is connected with a driven disc hub 11, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com