Device and method for mine car mechanized dumping

A mine car and ore dumping technology, which is applied in the field of mechanization and automatic mine dumping, to achieve the effects of low equipment failure rate and maintenance cost, cost saving, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

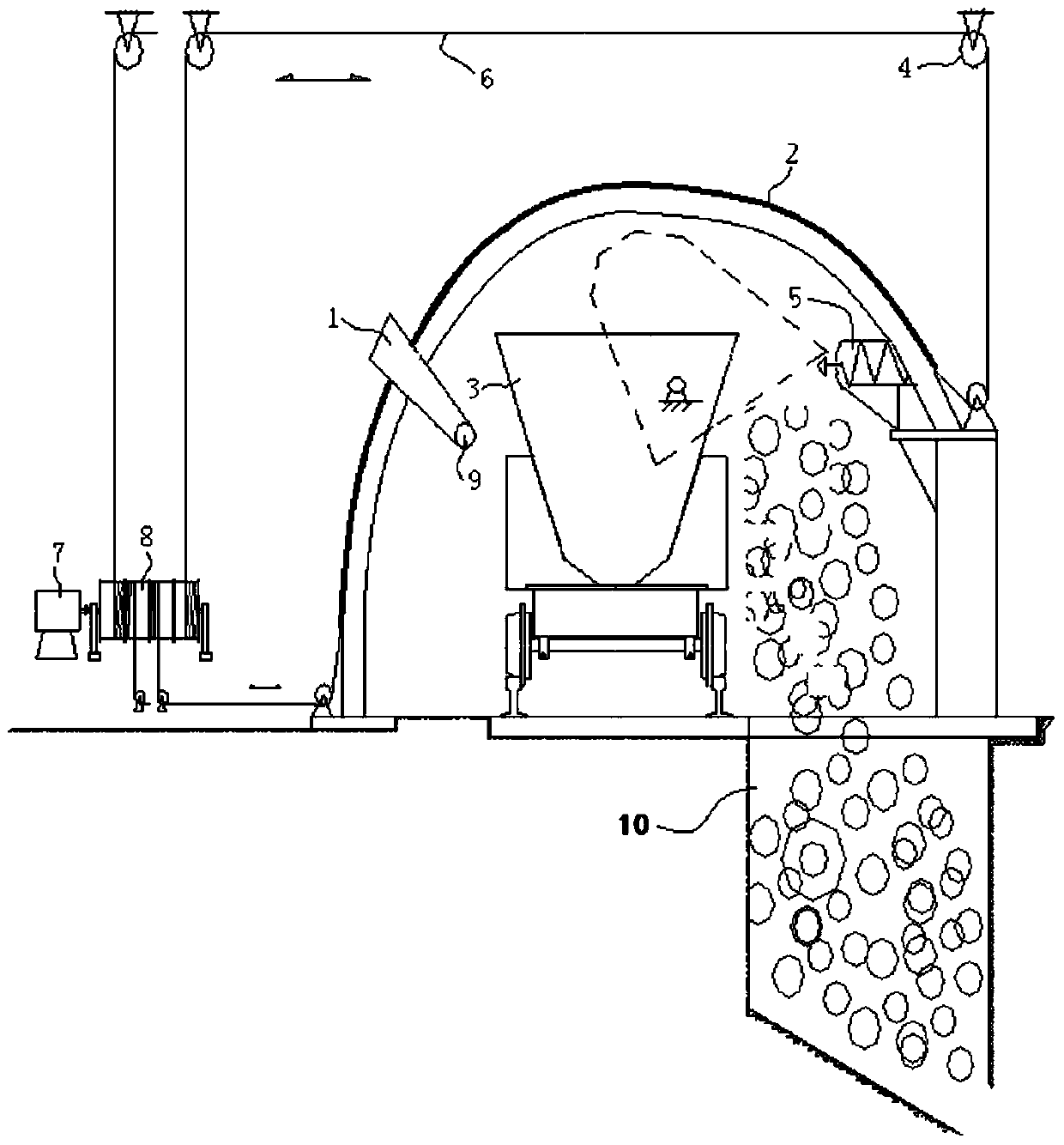

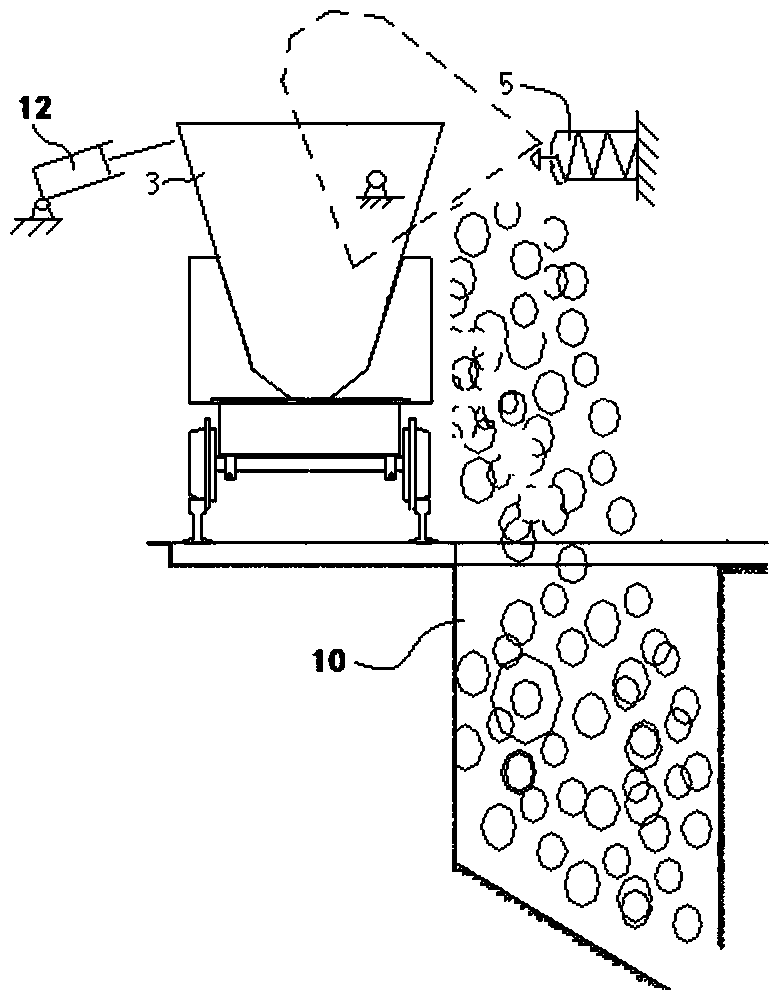

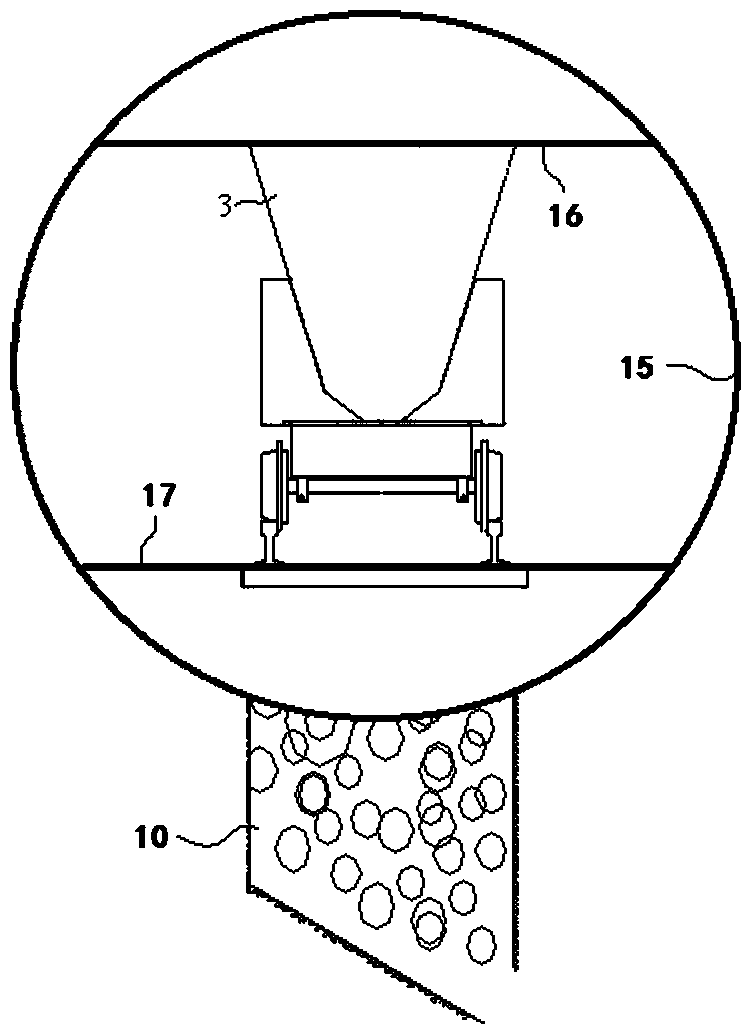

[0029] According to an embodiment of the present invention, such as figure 1 As shown, the mine car mechanical dumping device includes two pullers 1, two I-shaped steel arch rails 2, 5 mine car groups 3, two sets of pulley blocks 4, a set of car stop reset device 5, 4 steel wire ropes 6, A motor 7, a 4-group reel 8, a push rod 9, etc., can realize the mechanized ore dumping operation.

[0030] Working principle and operation method:

[0031] A. Ore dumping operation: run 5 mine carts 3 to the designated position, start the forward rotation button of motor 7, and under the pull of wire rope 6, puller 1 drives push rod 9 to push 5 mine carts 3 along the arch rail 2. Rise up and make a circular motion. When the mine car 3 presses the car stopper 5, the mine car 3 reaches the ore unloading position, press the stop button of the motor 7, the mine car 3 starts to unload the ore, and completes the ore dumping operation.

[0032] B. Reset operation: Press the reverse button of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com