Assembled concrete traffic pavement and construction method thereof

A concrete and prefabricated technology, which is applied in the direction of roads, roads, pavement details, etc., can solve the problems of large amount of concrete and broken joints, and achieve the effect of tight connection, convenient transportation and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

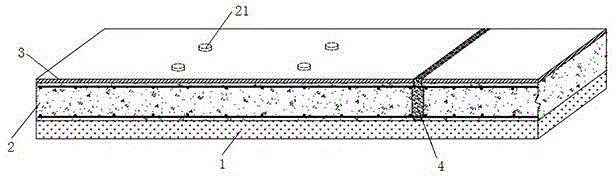

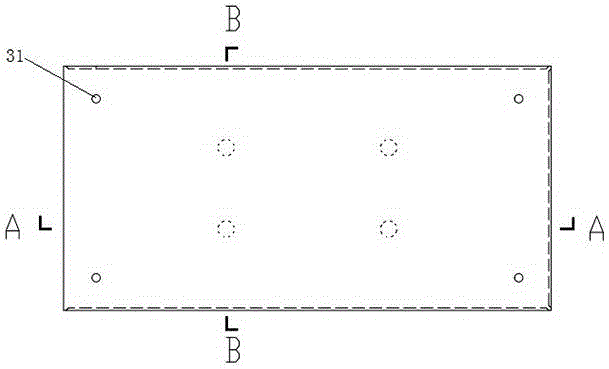

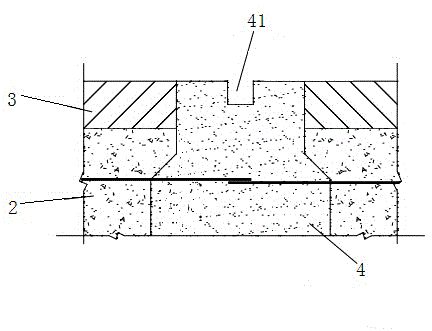

[0062] Such as figure 1 As shown, a prefabricated concrete traffic pavement is formed by splicing pavement prefabricated parts. The pavement prefabricated parts include an upper layer of wear-resistant layer 3 and a lower layer of stressed structure layer 2. The wear-resistant layer 3 and the stressed structure Layer 2 is fixedly connected, and there is a gap at the joint of the pavement prefabricated parts that are spliced with each other, and concrete is poured in the gap to form a gap stress layer 4. The thickness of the wear-resistant layer 3 is 20mm, and the thickness of the structural stress layer is 80mm.

[0063] The wear-resistant layer is cast from modified ECC ductile ultra-high performance concrete, and the modified ECC ductile ultra-high performance concrete includes the following raw material components in parts by weight:

[0064] Strength not less than 42.5 grade Portland cement or 750 parts of ordinary Portland cement;

[0065] 32 parts of silica fume with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com